Magnetic recording medium, production method thereof and magnetic disc apparatus

a technology of magnetic disc and recording medium, which is applied in the direction of instruments, nanoinformatics, patterned record carriers, etc., can solve the problems of increasing production costs, surface properties of the medium deteriorating, and difficulty in coping with density increas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

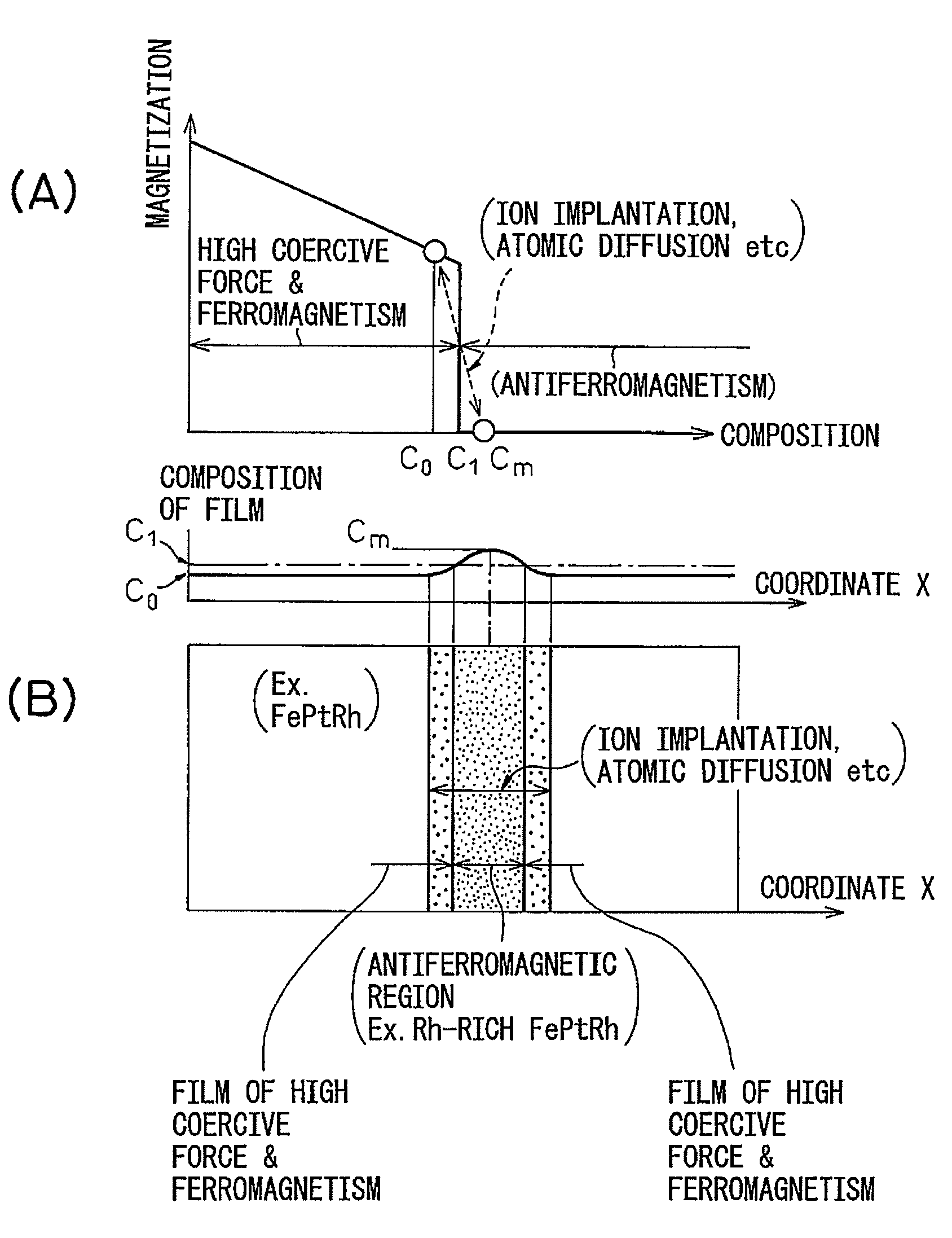

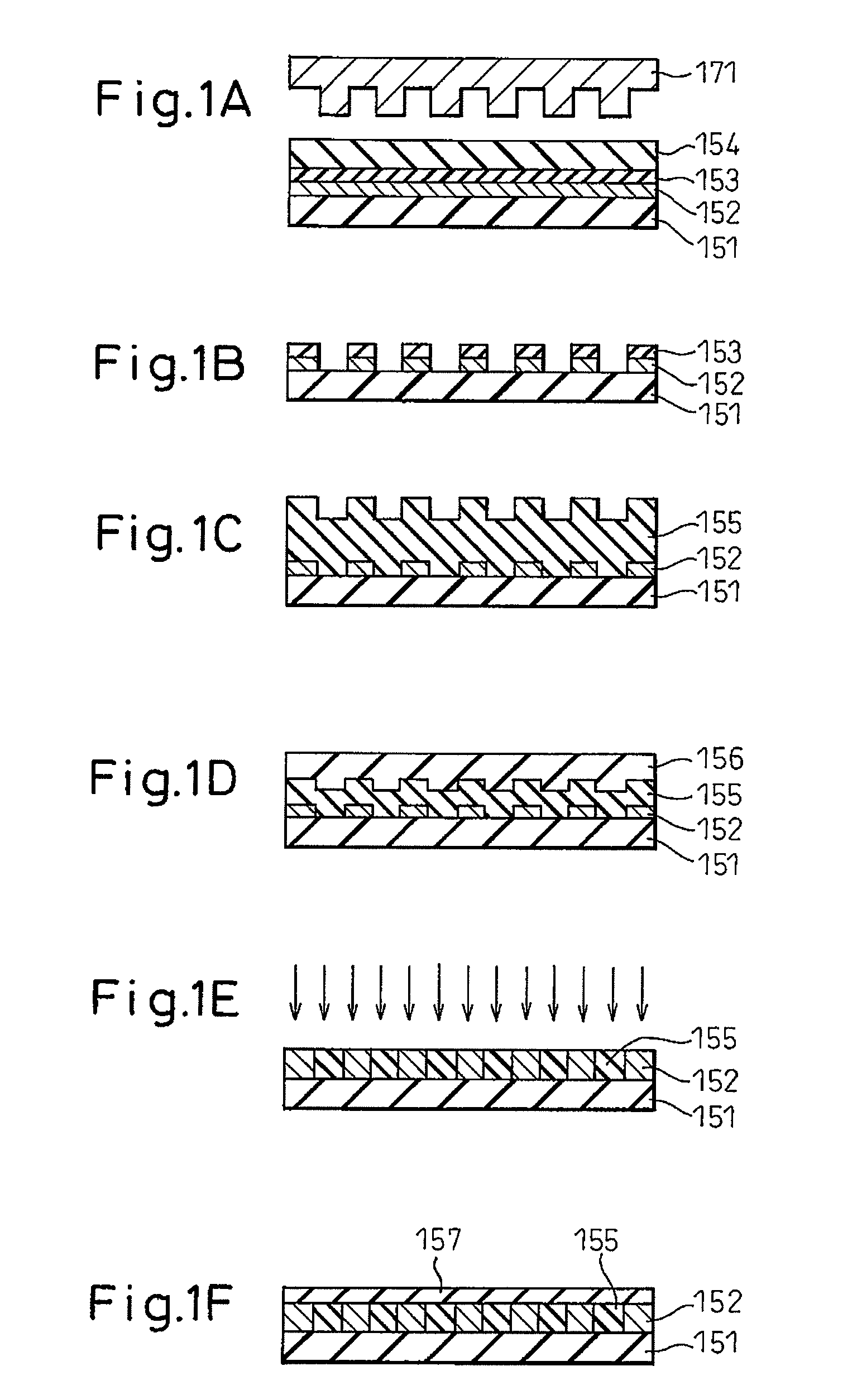

[0047]Preferred embodiments of the present invention are described below by referring to the attached drawings. In the following, a discrete track medium is recited as the medium and an embodiment of implanting or diffusing rhodium (Rh) in an FePt-based alloy for forming a magnetic recording layer is recited, but the present invention is not limited to these embodiments.

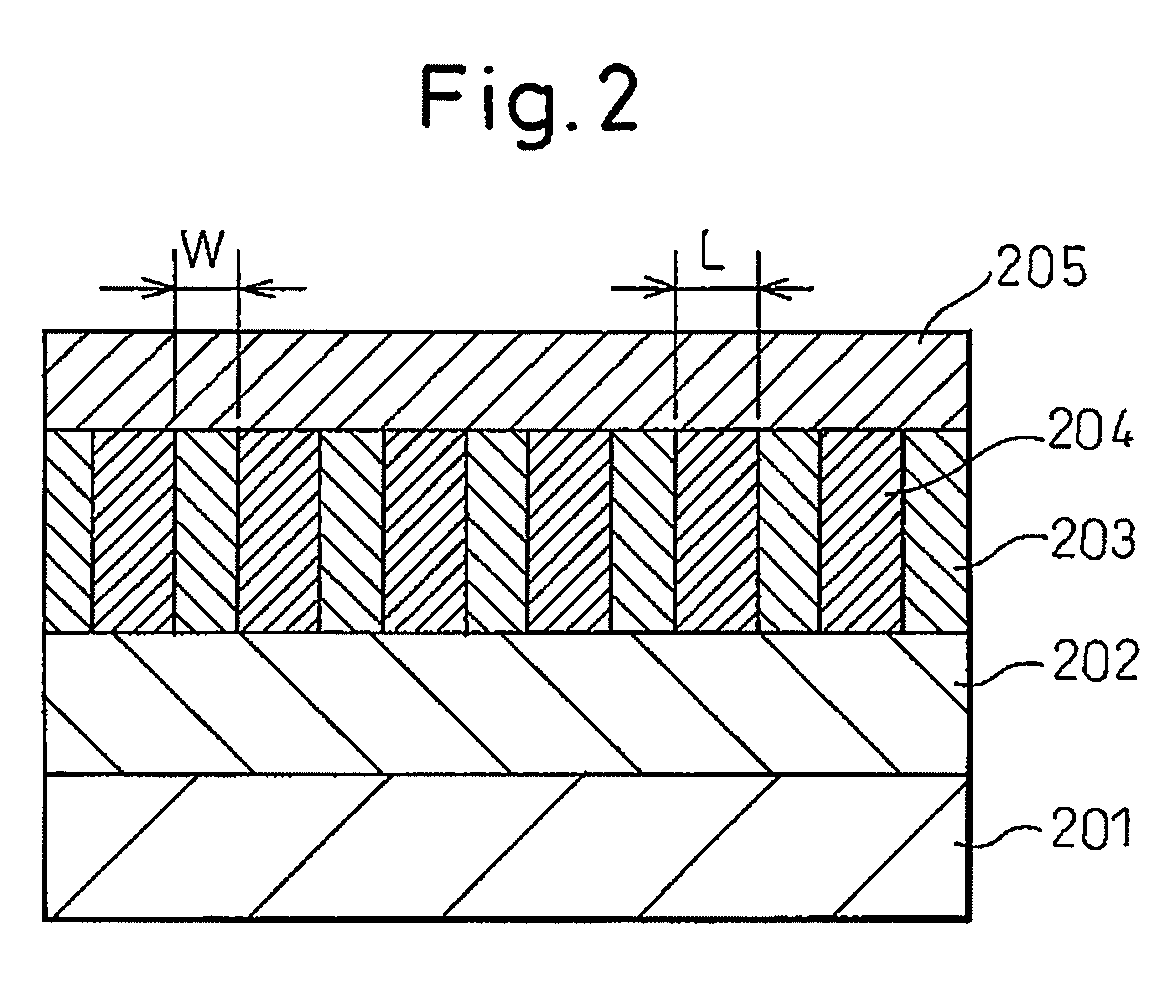

[0048]The magnetic recording medium of the present invention is used in digital magnetic recording and as described above, the magnetic recording layer deposited on a nonmagnetic substrate contains a plurality of recording track regions extending in the circumferential direction, each composed of a plurality of continuous or isolated bits and formed of a ferromagnetic material, and a track-to-track separation region located between the recording track regions adjacent to each other and formed of an antiferromagnetic material.

[0049]FIGS. 4A and 4B show a magnetic disk as a typical example of the magnetic recording med...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com