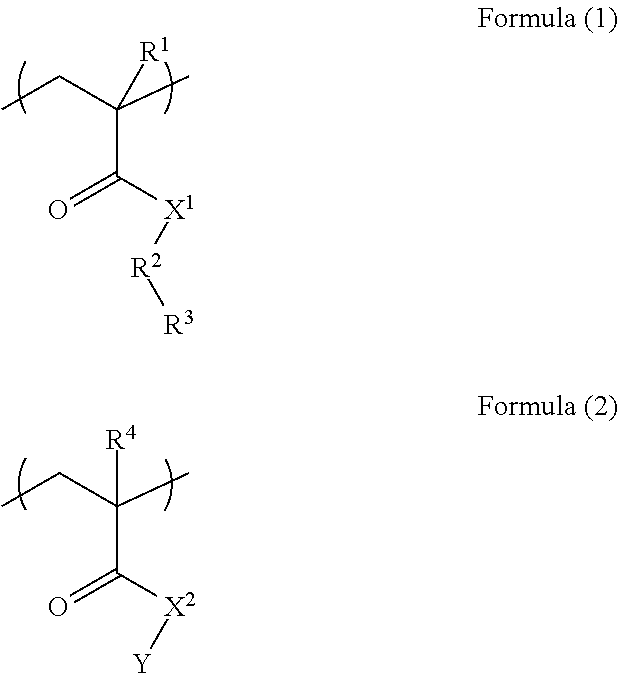

Resist underlayer film-forming composition for lithography containing polymer having acrylamide structure and acrylic acid ester structure

a technology of acrylic acid ester and resist, which is applied in the direction of photomechanical equipment, photosensitive material processing, instruments, etc., can solve the problems of reducing the film thickness of the resist, the influence of standing waves, and the diffuse reflection of active rays on the substrate, etc., and achieves good resist pattern shape, high thermal stability, and easy and accurate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

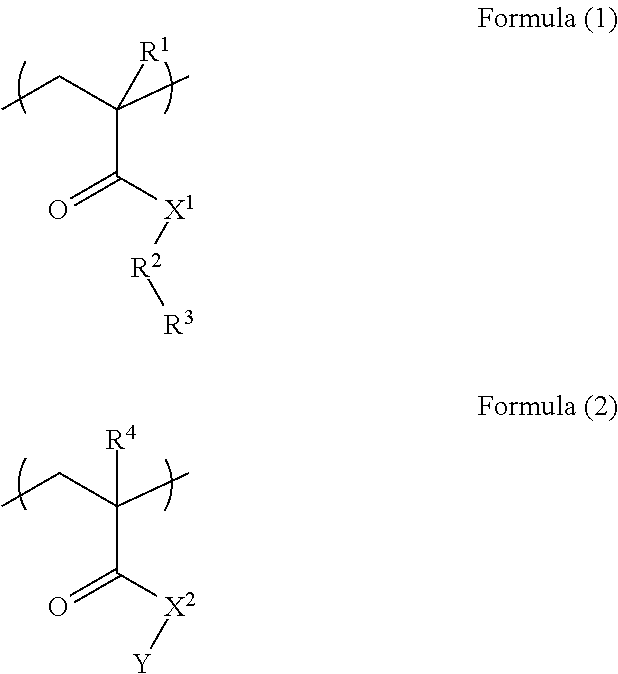

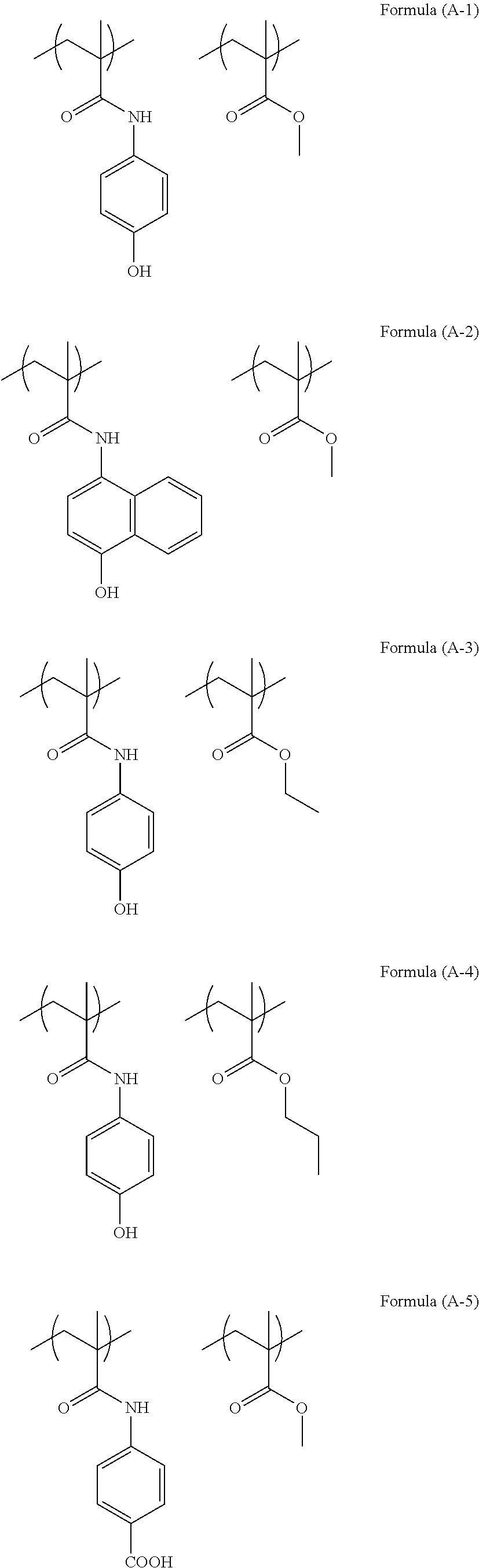

[0088]20.0 g of N-(4-hydroxyphenyl)methacrylamide (manufactured by Osaka Organic Chemical Industry Ltd.), 11.3 g of methyl methacrylate (manufactured by Tokyo Chemical Industry Co., Ltd.), and 3.7 g of 2,2-azobis(isobutylnitrile) (manufactured by Tokyo Chemical Industry Co., Ltd.) were added to 140.2 g of propylene glycol monomethyl ether, and dissolved therein. This solution was added dropwise to a 300 mL flask containing 58.5 g of propylene glycol monomethyl ether heated to 85° C., and after the completion of the dropwise addition, the mixture was stirred for approximately 15 hours. After the completion of the reaction, to this solution, 45 g of a cation exchange resin (trade name: DOWEX [registered trademark] 550A, manufactured by Muromachi Technos Co., Ltd.) and 45 g of an anion exchange resin (trade name: Amberlite [registered trademark] 15JWET, manufactured by Organo Corporation) were added, and the mixture was subjected to ion exchange treatment at room temperature for 4 hour...

synthesis example 2

[0089]16.0 g of N-(4-hydroxyphenyl)methacrylamide (manufactured by Osaka Organic Chemical Industry Ltd.), 21.1 g of methyl methacrylate (manufactured by Tokyo Chemical Industry Co., Ltd.), and 4.3 g of 2,2-azobis(isobutylnitrile) (manufactured by Tokyo Chemical Industry Co., Ltd.) were added to 165.5 g of propylene glycol monomethyl ether, and dissolved therein. This solution was added dropwise to a 300 mL flask containing 68.9 g of propylene glycol monomethyl ether heated to 85° C., and after the completion of the dropwise addition, the mixture was stirred for approximately 15 hours. After the completion of the reaction, to this solution, 42.0 g of a cation exchange resin (trade name: DOWEX [registered trademark] 550A, manufactured by Muromachi Technos Co., Ltd.) and 42.0 g of an anion exchange resin (trade name: Amberlite [registered trademark] 15JWET, manufactured by Organo Corporation) were added, and the mixture was subjected to ion exchange treatment at room temperature for 4 ...

example 1

[0092]52.7 g of the polymer solution obtained in Synthesis Example 1 (the solution of a polymer containing N-(4-hydroxyphenyl) methacrylamide unit and methyl methacrylate unit at 50 mol %:50 mol %), 1.6 g of a blocked isocyanate-based crosslinking agent (blocked polyisocyanate protected with an oxime group based on an isophorone diisocyanate structure, trade name: VESTANAT [registered trademark] B1358, manufactured by Degussa Japan Co., Ltd.), and 0.06 g of a surfactant (trade name: MEGAFACE [registered trademark] R-40, manufactured by DIC Corporation) were dissolved in 22.4 g of propylene glycol monomethyl ether acetate, 31.5 g of propylene glycol monomethyl ether, and 11.2 g of gamma butyllactone to prepare a solution of a resist underlayer film-forming composition for use in a lithography process using a multilayer film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com