High tensile strength steel wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

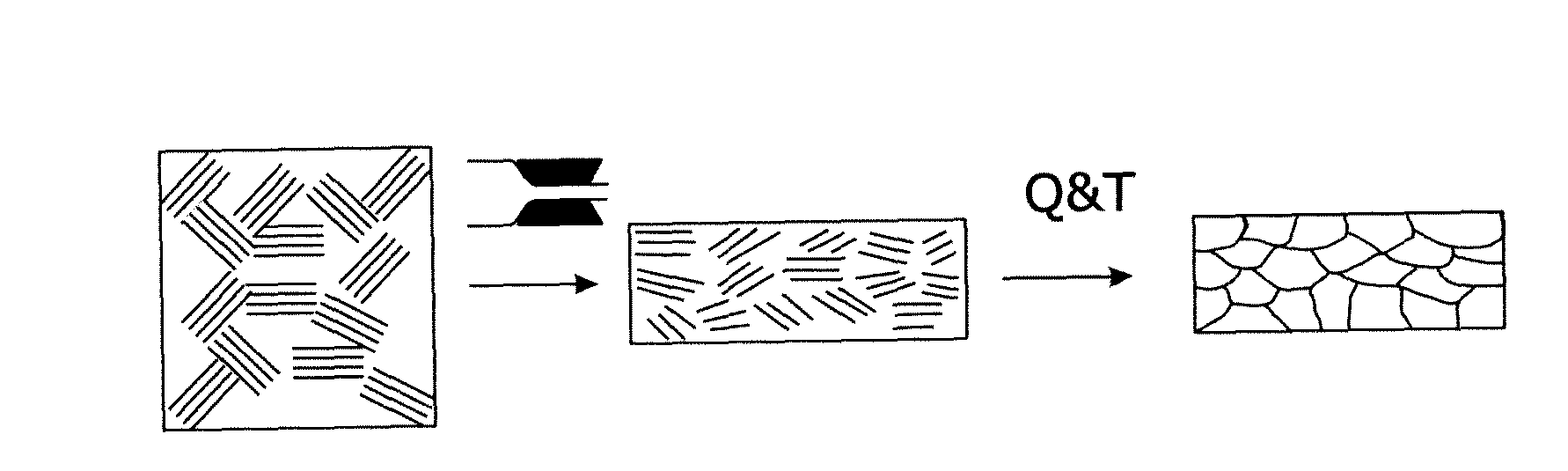

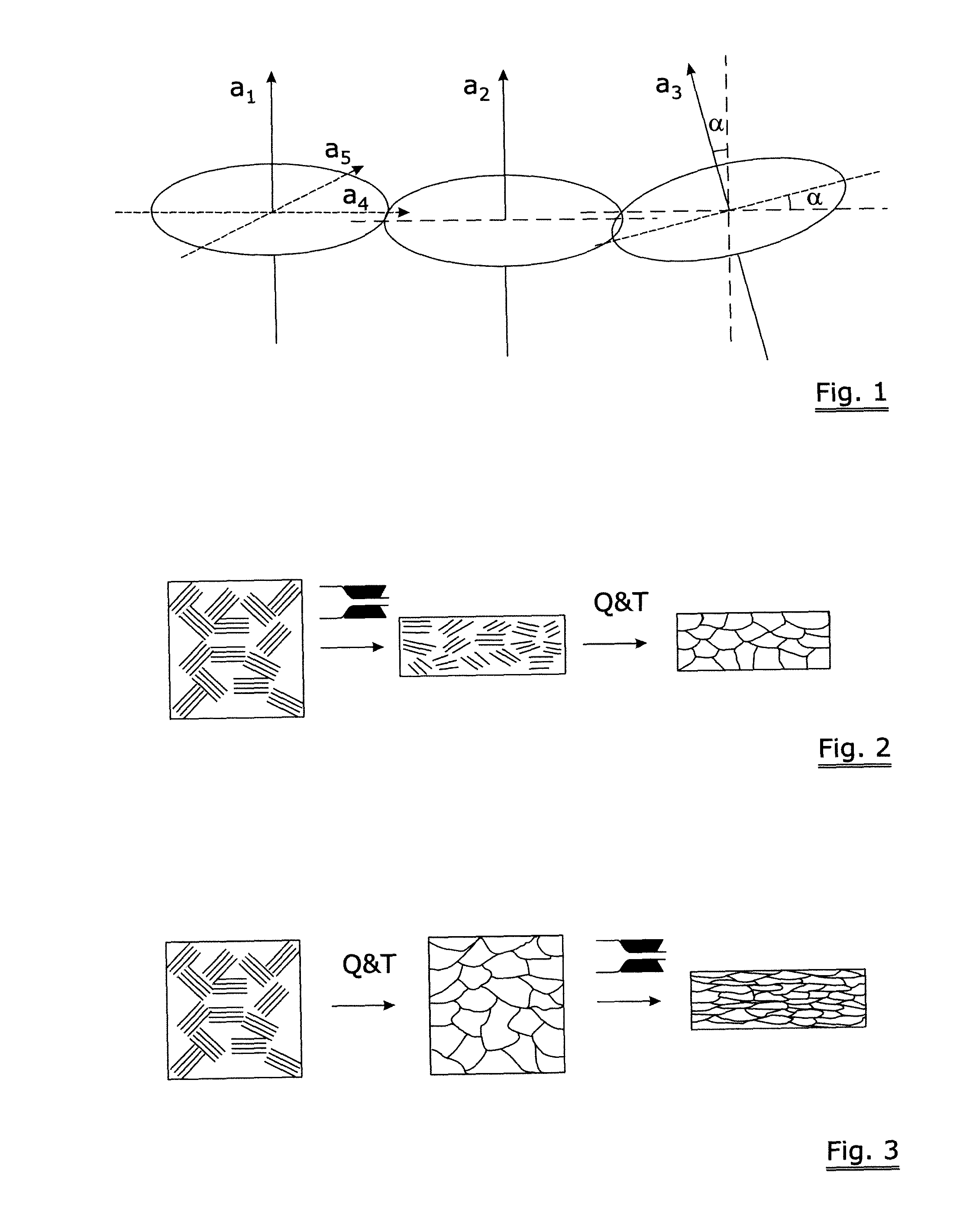

Method used

Image

Examples

embodiment 1

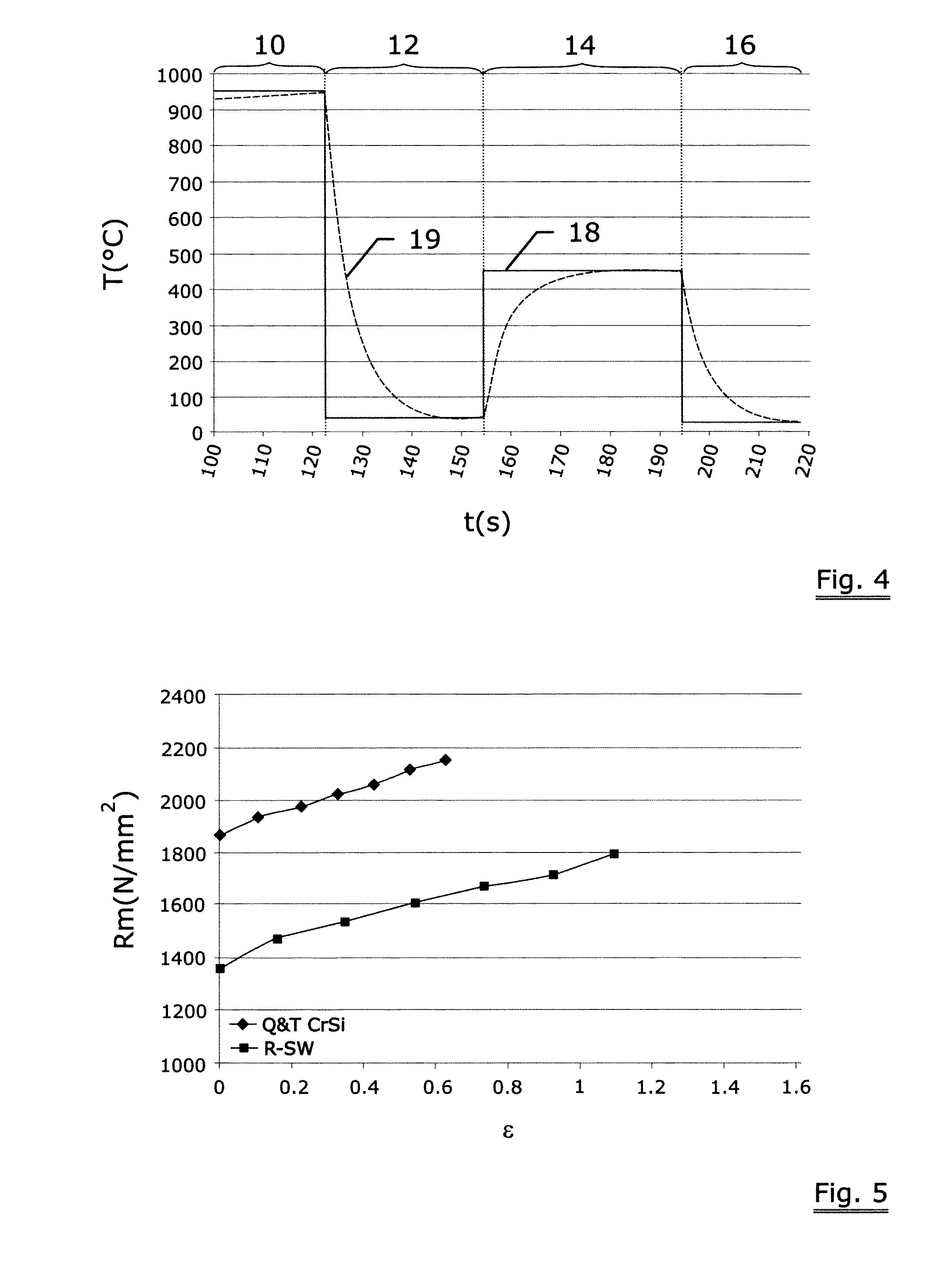

[0049]FIG. 4 illustrates a suitable temperature versus time curve applied to a steel wire or wire rod with a diameter of 5.29 mm and with following steel composition:[0050]% wt C=0.55[0051]% wt Si=1.4[0052]% wt Cr=0.6[0053]% wt Mn=0.7

the balance being iron and unavoidable impurities.

[0054]The starting temperature of martensite transformation Ms of this steel is about 280° C. and the temperature Mf, at which martensite formation ends is about 100° C.

[0055]The various steps of the process are as follows:[0056]a first austenitizing step (10) during which the steel wire stays in a furnace at about 950° C. during 120 seconds,[0057]a second quenching step (12) for martensite transformation in oil at a temperature below 100° C. during at least 20 seconds;[0058]a third tempering step (14) for increase the toughness at a temperature above 320° C. during less than 60 seconds; and[0059]a fourth cooling step (16) at room temperature during 20 or more seconds.

[0060]Curve 18 is the temperature cu...

embodiment 2

[0067]In this embodiment, a similar thermal treatment of embodiment 1 was applied to a steel wire with a diameter of 3.75 mm and with the following steel composition:[0068]% wt C=0.55[0069]% wt Si=1.4[0070]% wt Cr=0.6[0071]% wt Mn=0.7

the balance being iron and unavoidable impurities.

[0072]The steel wire after thermal treatment mainly has martensitic microstructure. The steel wire further undergoes six passes drawing steps with a diameter reduction to 2.8 mm. The properties of the steel wire after each pass are shown in table 2. Although an extreme high tensile strength is obtained after six passes, the steel wire still has sufficient ductility as indicated by a reduction in area of 52.8%. Moreover, the ductility of the steel wire is ensured during the whole drawing process, which can be verified by the reductions in area of the steel wires after one to six passes all being above 52.8% as shown in table 2.

TABLE 2Properties of a steel wire with an initial diameter of 3.75 mmdrawn in s...

embodiment 3

[0073]Different from the samples of embodiment 2, in this example, after a similar thermal treatment, the martensitic steel wire with 3.75 mm diameter is drawn by three passes.

[0074]The diameter, diameter reduction, section reduction, cumulative section reduction, tensile strength, tensile strength variation and reduction in area after each pass of the steel wire drawn by this three passes process are summarized in table 3.

[0075]The average diameter reduction of each pass is about 9.5% for three passes process which is almost a double of that of six passes process as shown in embodiment 1 and 2. The tensile strength (Rm) of three passes drawn wire (SW3) as a function of section reduction (Δs) is plot in FIG. 6 in comparison with the tensile strength of six passes drawn wires of embodiment 1 (SW1) and embodiment 2 (SW2). As shown in FIG. 6, the increase of tensile strength is almost proportional to the increase of section reduction for both the three and the six passes drawn steel wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com