Light-regulation membrane

a technology of light regulation membrane and light-regulating film, which is applied in the direction of thin material processing, instruments, chemistry apparatus and processes, etc., can solve the problems of inability to effectively block ultraviolet light, and inability to achieve perfect heat insulation effect of conventional heat insulation films, etc., to achieve excellent support effect, easy installation, repair and replacement of light-regulating membran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

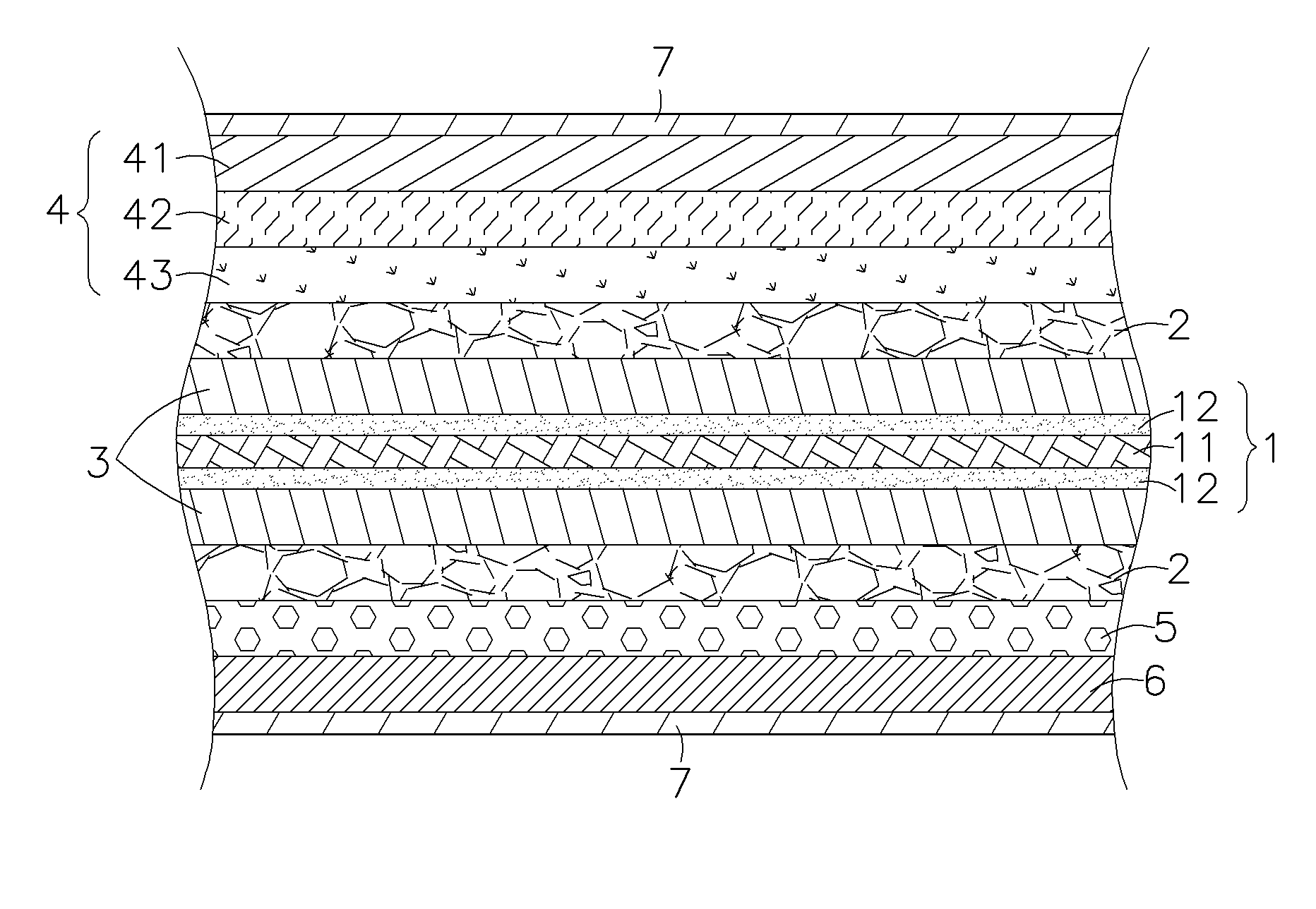

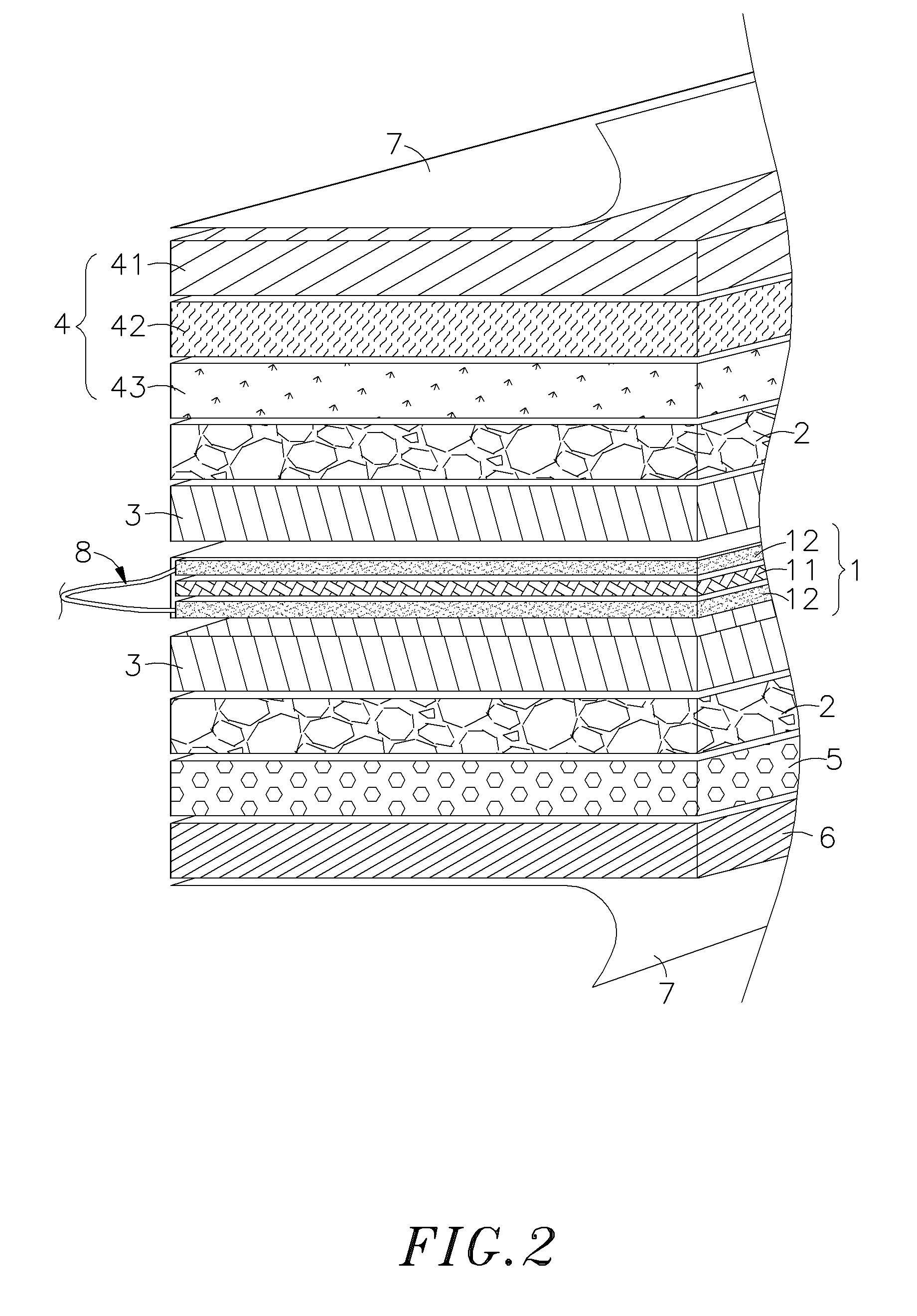

[0019]Referring to FIGS. 1-3, a light-regulation membrane in accordance with the present invention is shown comprising a PDLC (polymer dispersed liquid crystal) film 1, two polymer compound layers 2, a plurality of PSA (pressure sensitive adhesive) layers 3, a surface structure 4, an anti-radiation layer 5, an adhesion layer 6, and two protective films 7.

[0020]The PDLC film 1 comprises a liquid crystal layer 11 and two conducting layers 12. The liquid crystal layer 11 is sandwiched between the two conducting layers 12. The liquid crystal layer 11 can be prepared from a compound of hydroxyl polyfunctional (meth) acrylates and nematic liquid crystal cured with a polyisocyanate compound crosslinking agent. The conducting layers 12 are made by means of depositing ITO (indium tin oxide) on a base layer of PET (polyethylene terephthalate by means of spattering deposition.

[0021]The polymer compound layers 2 are respectively formed on the two conducting layers 12. Further, the polymer compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface structure | aaaaa | aaaaa |

| adhesion | aaaaa | aaaaa |

| pressure sensitive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com