Electronic Device Module Comprising an Ethylene Multi-Block Copolymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific embodiments

Example A

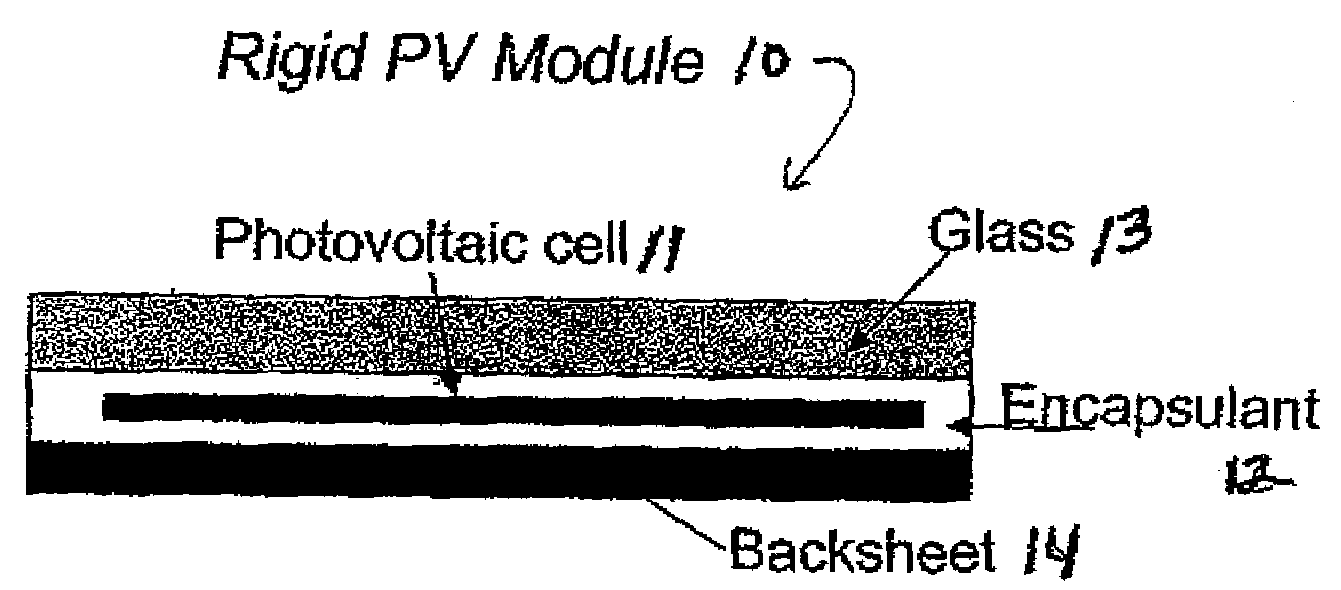

[0085]A monolayer 15 mil thick protective cast film is made from a blend comprising 80 wt % ethylene / 1-octene multi-block copolymer (5 MI, 0.87 g / cc overall density; 30% hard segment, 70% soft segment having a density of about 0.85 g / cc), 20 wt % maleic anhydride (MAH) modified ethylene / 1-octene (ENGAGE® polyolefin grafted at a level of about 1 wt % MAH and having a post-modified MI of about 1.25 g / 10 min and a density of about 0.87 g / cc), 0.1 wt % of Chimassorb® 944, 0.2 wt % of Naugard® P, and 0.3 wt % of Cyasorb® UV 531. A Solar cell module is prepared using a solar cell lamination process at 150 C. in which the protective film is located between a transparent superstrate (usually glass) and the solar cell, and between the solar cell and a backskin material.

example b

[0086]A monolayer 15 mil thick protective cast film is made from a blend comprising 90 wt % ethylene / 1-octene multi-block copolymer (5 MI, 0.87 g / cc overall density; 30% hard segment, 70% soft segment having a density of about 0.85 g / cc), 10 wt % maleic anhydride (MAH) modified ethylene / 1-octene (ENGAGE® polyolefin grafted at a level of about 1 wt % MAH and having a post-modified MI of about 1.25 g / 10 min and a density of about 0.87 g / cc), 0.1 wt % of Chimassorb® 944, 0.2 wt % of Naugard® P, and 0.3 wt % of Cyasorb® UV 531. A Solar cell module is prepared using a solar cell lamination process at 150 C in which the protective film is located between a transparent superstrate (usually glass) and the solar cell, and between the solar cell and a backskin material.

Formulation and Processing Procedures:

[0087]Step 1: Use ZSK-30 extruder with Adhere Screw to compound resin and additive package with Amplify.

[0088]Step 2: Dry the material from Step 2 for 4 hour at 100 F maximum (use W&C canis...

example c

Block Copolymer Polyolefin-Based Encapsulant Film

[0096]An ethylene / 1-octene block copolymer developed by The Dow Chemical Company is used for this example. The density of this resin is 0.877 g / cm3 and melt index is 5 g / 10 min (measured based on standard ASTM D1238, condition 190 C / 2.16 kg). The resin contains 1000 ppm of antioxidant Irganox-168. Several additives are selected to add functionality or improve the long term stability of the resin. The additives are UV-absorbent Cyasorb UV 531, UV-stabilizer Chimassorb 944 LD, antioxidant Tinuvin 622 LD, vinyltrimethoxysilane (VTMS), and peroxide Luperox-101. The formulation (by weight) is listed in Table 3.

TABLE 3Film FormulationFormulation ComponentWeight percentEthylene / 1-octene block copolymer98.45(MI 5, 0.877 den.)Cyasorb UV 5310.3Chimassorb 944 LD0.1Tinuvin 622 LD0.1Irganox-168Silane (Dow Corning Z-6300)1Luperox-1010.05Total100

TABLE 4Ethylene / 1-Octene Block Copolymer CompositionOverallOcteneOcteneOverallOcteneOcteneOctenein softin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com