Biaxially Oriented Polyarylene Sulfide Film and Laminated Polyarylene Sulfide Sheets Comprising the Same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

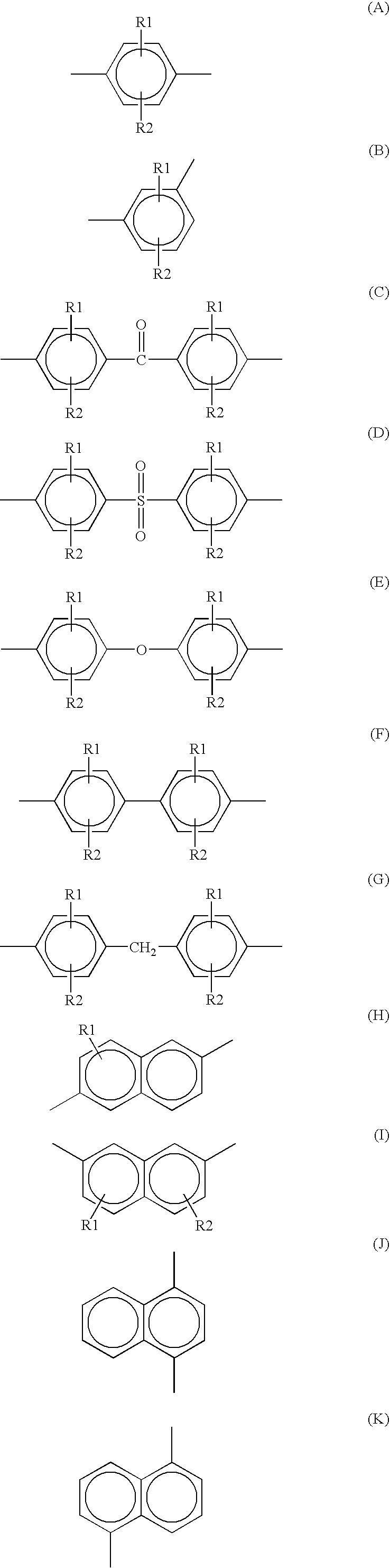

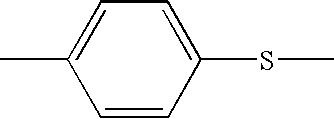

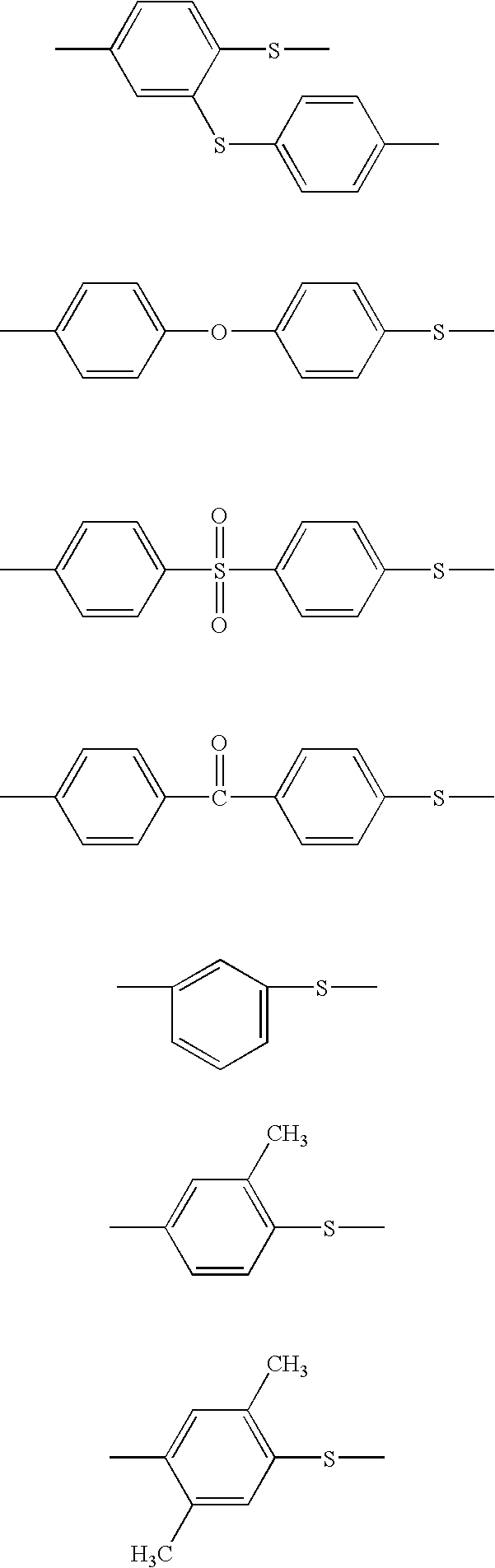

Method used

Image

Examples

reference example 1

Polymerization of PPS (PPS-1)

[0166] A 70-L autoclave equipped with a stirrer was charged with 8,267.37 g (70.00 moles) of 47.5% sodium hydrosulfide, 2,957.21 g (70.97 moles) of 96% sodium hydroxide, 11,434.50 g (115.50 moles) of N-methyl-2-pyrrolidone (NMP), 2,583.00 g (31.50 moles) of sodium acetate and 10,500 g deionized water, and the mixture was gradually heated to 245° C. over about 3 hours at normal pressures with nitrogen passing into it, and after 14,780.1 g water and 280 g NMP were distilled away, the reaction container was cooled to 160° C. The amount of water remaining in the system, including water consumed in hydrolysis of NMP, was 1.06 moles per mole of the alkali metal sulfide charged. The amount of hydrogen sulfide scattered was 0.02 mol per mol of the alkali metal sulfide charged.

[0167] Then, 10,235.46 g (69.63 moles) of p-dichlorobenzene and 9,009.00 g (91.00 moles) of NMP were added, and the reaction container was sealed under a nitrogen gas and heated to 238° C...

reference example 2

Preparation of Copolymerized PPS Composition (PPS-2)

[0169] An autoclave was charged with 100 moles of sodium sulfide.9H2O, 45 moles of sodium hydroxide and 25-L N-methyl-2-pyrrolidone (referred to hereinafter as NMP), and the mixture was gradually heated to 220° C. under stirring to remove the contained water by distillation.

[0170] The system after conclusion of dehydration was charged with 86 moles of p-dichlorobenzene as a main monomer, 15 moles of m-dichlorobenzene as a minor monomer and 0.2 mole of 1,2,4-trichlorobenzene, together with 5-L NMP, then filled at 170° C. with 3 kg / cm2 nitrogen under pressurization, and heated to polymerize the mixture at 260° C. for 4 hours. After the polymerization was finished, the reaction mixture was cooled to precipitate the polymer in distilled water, which was then passed thorough a gauze having 150-mesh openings to recover a small massive polymer.

[0171] This polymer was washed 5 times with distilled water at 90° C. and dried at 120° C. un...

reference example 3

Preparation of Copolymerized PPS Composition (PPS-3)

[0172] An autoclave was charged with 100 moles of sodium sulfide.9H2O, 45 moles of sodium hydroxide and 25-L NMP, and the mixture was gradually heated to 220° C. under stirring to remove the contained water by distillation.

[0173] The system after conclusion of dehydration was charged with 94.8 moles of p-dichlorobenzene as a main monomer, 5 moles of m-dichlorobenzene as a minor monomer and 0.2 mole of 1,2,4-trichlorobenzene, together with 5-L NMP, then filled at 170° C. with 3 kg / cm2 nitrogen under pressurization, and heated to polymerize the mixture at 260° C. for 4 hours. After the polymerization was finished, the reaction mixture was cooled to precipitate the polymer in distilled water, which was then passed thorough a gauze having 150-mesh openings to recover a small massive polymer.

[0174] This polymer was washed 5 times with distilled water at 90° C. and dried at 120° C. under reduced pressure to give a white particulate co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com