High-performance easy-to-process nickel-based deformation high-temperature alloy and preparation method thereof

A deformed superalloy and easy-to-process technology, which is applied in the field of high-performance and easy-to-process nickel-based deformed superalloy and its preparation, and can solve problems such as being unsuitable for complex-shaped parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

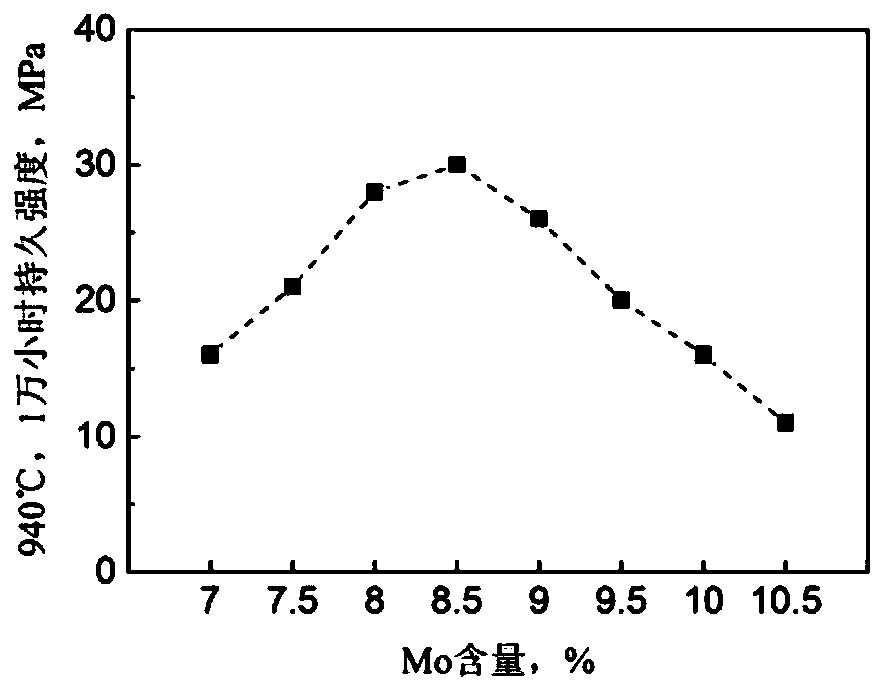

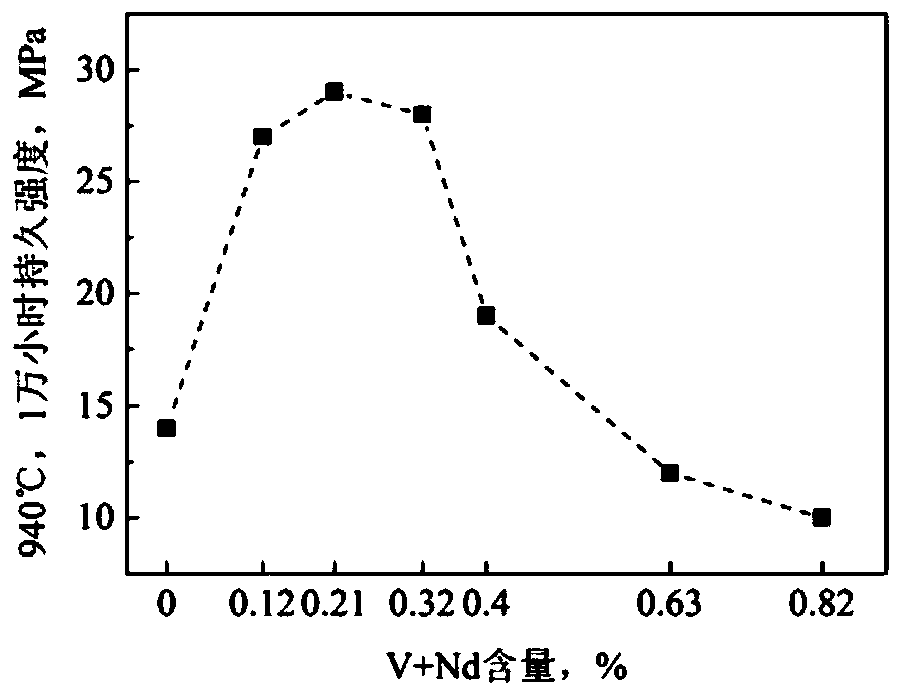

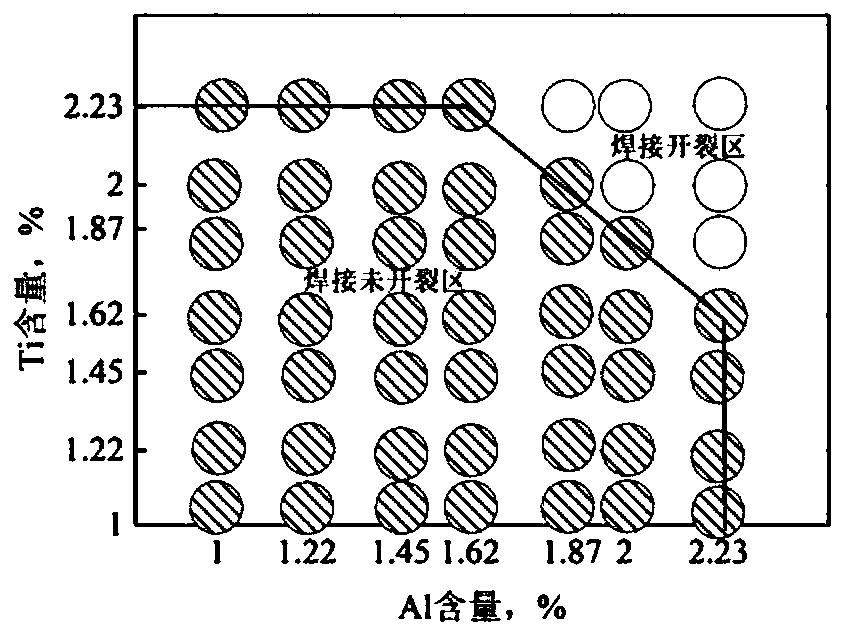

Method used

Image

Examples

Embodiment 1

[0058] A high-performance easy-to-process nickel-based deformed superalloy and its preparation method, including C, Cr, Co, Mo, Al, Ti, B, V, Nd, Nb, Fe, Zr, Ni and unavoidable impurities, obtained by actual measurement See Table 1 for the mass percentages of each element and the mass percentages of impurity elements.

[0059] The preparation method of the above-mentioned high-temperature-resistant, long-life and easy-to-process nickel-based deformable superalloy is as follows:

[0060] Raw materials C, Si, Mn, Cr, Co, Mo, Al, Ti, B, V, Nd, Nb, Fe, Zr, Ni are carefully selected and the purity meets the requirements, and the mass percentages are C0.03%, Cr20%, Co10 .5%, Mo9%, Al 1.5%, Ti2.0%, B0.004%, Si0.15%, Mn0.3%, V0.03%, Nd 0.06%, Nb0.1%, Fe1%, Zr0 .01%, the balance being Ni and unavoidable impurities. Put it into a vacuum induction melting furnace, and melt in the vacuum induction melting furnace under the vacuum condition of 0.1-0.6Pa; after all the raw materials are m...

Embodiment 2

[0063] A high-performance easy-to-process nickel-based deformed superalloy and its preparation method, including C, Cr, Co, Mo, Al, Ti, B, V, Nd, Nb, Fe, Zr, Ni and unavoidable impurities, obtained by actual measurement See Table 1 for the mass percentages of each element and the mass percentages of impurity elements.

[0064] The preparation method of the above-mentioned high-temperature-resistant, long-life and easy-to-process nickel-based deformable superalloy is as follows:

[0065] Raw materials C, Si, Mn, Cr, Co, Mo, Al, Ti, B, V, Nd, Nb, Fe, Zr, Ni are selected and the purity meets the requirements, and the mass percentages are C0.06%, Cr19%, Co10 %, Mo8.5%, Al 1.55%, Ti2.0%, B0.0045%, Si0.15%, Mn0.22%, V0.05%, Nd 0.05%, Nb0.26%, Fe1.5% , Zr0.03%, the balance being Ni and unavoidable impurities. Put it into a vacuum induction melting furnace, and melt in the vacuum induction melting furnace under the vacuum condition of 0.1-0.6Pa; after all the raw materials are melte...

Embodiment 3

[0068] A high-performance easy-to-process nickel-based deformed superalloy and its preparation method, including C, Cr, Co, Mo, Al, Ti, B, V, Nd, Nb, Fe, Zr, Ni and unavoidable impurities, obtained by actual measurement See Table 1 for the mass percentages of each element and the mass percentages of impurity elements.

[0069] The preparation method of the above-mentioned high-temperature-resistant, long-life and easy-to-process nickel-based deformable superalloy is as follows:

[0070] Raw materials C, Si, Mn, Cr, Co, Mo, Al, Ti, B, V, Nd, Nb, Fe, Zr, Ni are carefully selected and the purity meets the requirements, and the mass percentages are C0.04%, Cr19%, Co10 %, Mo8.8%, Al 1.65%, Ti2.2%, B0.0045%, Si0.15%, Mn0.15%, V0.12%, Nd 0.1%, Nb0.26%, Fe1.5% , Zr0.03%, the balance being Ni and unavoidable impurities. Put it into a vacuum induction melting furnace, and melt in the vacuum induction melting furnace under the vacuum condition of 0.1-0.6Pa; after all the raw materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com