Thin film for package of alkaline battery and thin air battery using the same

a technology of alkaline batteries and thin film, which is applied in the direction of cell components, cell components, jackets/cases materials, etc., can solve the problems of inability to accommodate the battery in the volume allotted to the battery in a small electronic device, the inability to output small amounts, and the inability to use as the main power source for portable electronic devices or small audio systems. , to achieve the effect of preventing degradation of electrolyte, suppressing the expansion of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

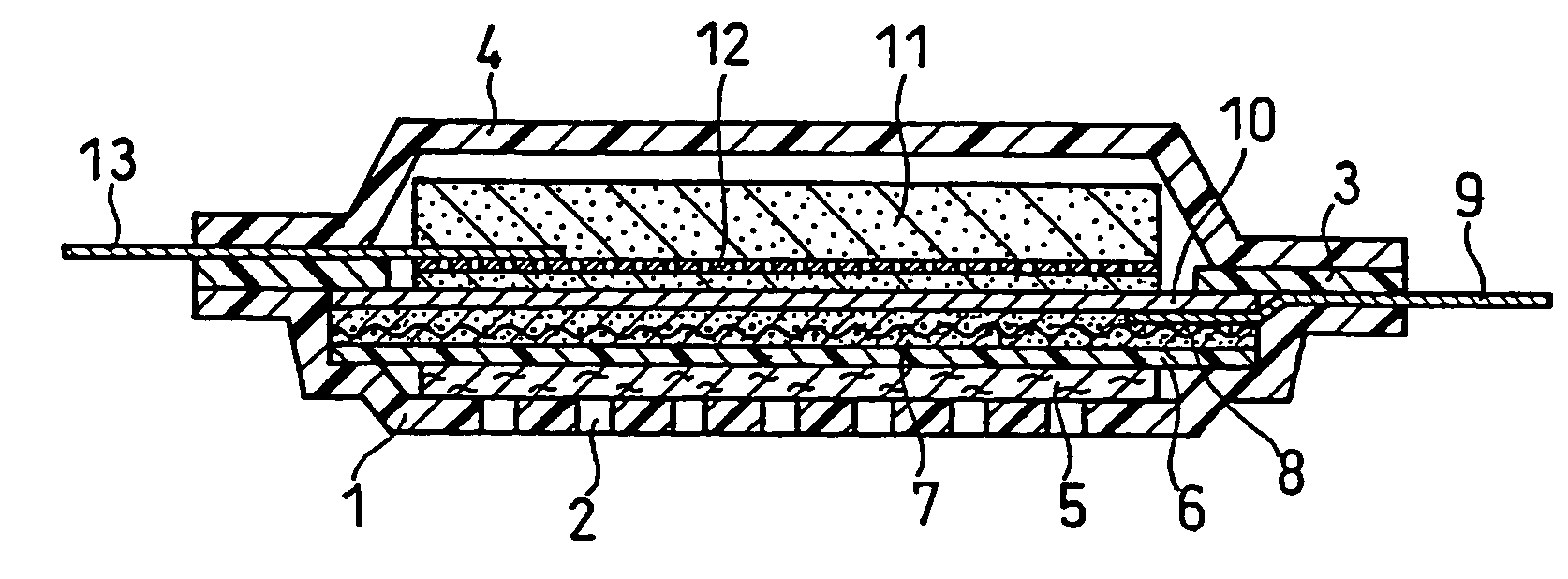

[0048] For sheet layers 1, 3 and 4 of a package, an acid-modified polypropylene (PPa) having a thickness of 0.02 mm was used as a hydrogen gas permeating material, PEN having a thickness of 0.035 mm was used as a gas barrier material, and a sheet constituted to be a three-layer structure of a total thickness of 0.075 mm wherein the both surfaces of the PEN was coated with PPa was used (tab-film (PPa—N), manufactured by Dai Nippon Printing Co. Ltd.).

[0049] The first sheet layer 1 was drawn using a hot press to have a depth of 0.6 mm. In the depression, vinylon fiber paper (thickness: 0.1 mm) as air diffusion paper 5 was placed so as to cover over an air inlet hole 2, and spot bonded with pitch to fix. On the vinylon fiber paper, a fine porous film of polytetrafluoroethylene (PTFE) (thickness: 0.1 mm) as a water repellent film 6, an air electrode 7 (thickness: 0.3 mm), and a fine porous film of polypropylene (PP) (thickness: 0.05 mm) as a separator 10 were sequentially stacked. Over ...

examples 2 to 14

[0056] Hydrogen gas permeating materials, gas barrier materials, and metal materials, the thicknesses thereof, and the compositions and thicknesses of packages composed of these materials are shown in Table 1. The hydrogen gas permeating materials and the gas barrier materials were adhered together by evenly roll-coating modified polybutadiene as an anchor coating agent with a substantially negligible thickness on the surface of the gas barrier material sheets, and bonding the hydrogen gas permeating material sheets thereto. Except using these, thin air batteries were fabricated in the same configurations as in Example 1.

TABLE 1Hydrogen gas permeatingGas barrier materialMetal materialComposition andmaterial and thicknessand thicknessand thicknessthickness ofthereof (mm)thereof (mm)thereof (mm)package (mm)Example 1PPa 0.02PEN 0.035—PPa / PEN / PPa 0.075Example 2PPa 0.02PET 0.035—PPa / PET / PPa 0.075Example 3PPa 0.02PPS 0.035—PPa / PPS / PPa 0.075Example 4PE 0.02PEN 0.035—PE / PEN / PE 0.075Exampl...

examples 15 to 18

[0057] Acid-modified polypropylene (PPa) having a thickness of 0.02 mm was used as hydrogen gas permeating materials, fluorine-containing polymer materials were used as gas barrier materials, and the combinations of the configuration and thicknesses thereof are shown in Table 1. The hydrogen gas permeating materials were adhered to the fluorine-containing polymer materials by surface-modifying the surfaces of the fluorine-containing polymer material sheets by corona discharge, roll-coating modified polybutadiene, which was an anchor coating agent, on the surface of the fluorine-containing polymer material sheets, and bonding the hydrogen gas permeating material sheets on the coating surface. Except using these, thin air batteries were fabricated in the same configurations as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com