Method of manufacturing electrode for electrochemical device

a manufacturing method and electrochemical technology, applied in the manufacturing process of electrodes, cell components, electrolytic capacitors, etc., can solve the problems of inability to endure long-term use, easy cracking or collapse, uneven surfaces can be easily formed, etc., and achieve the effect of efficient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

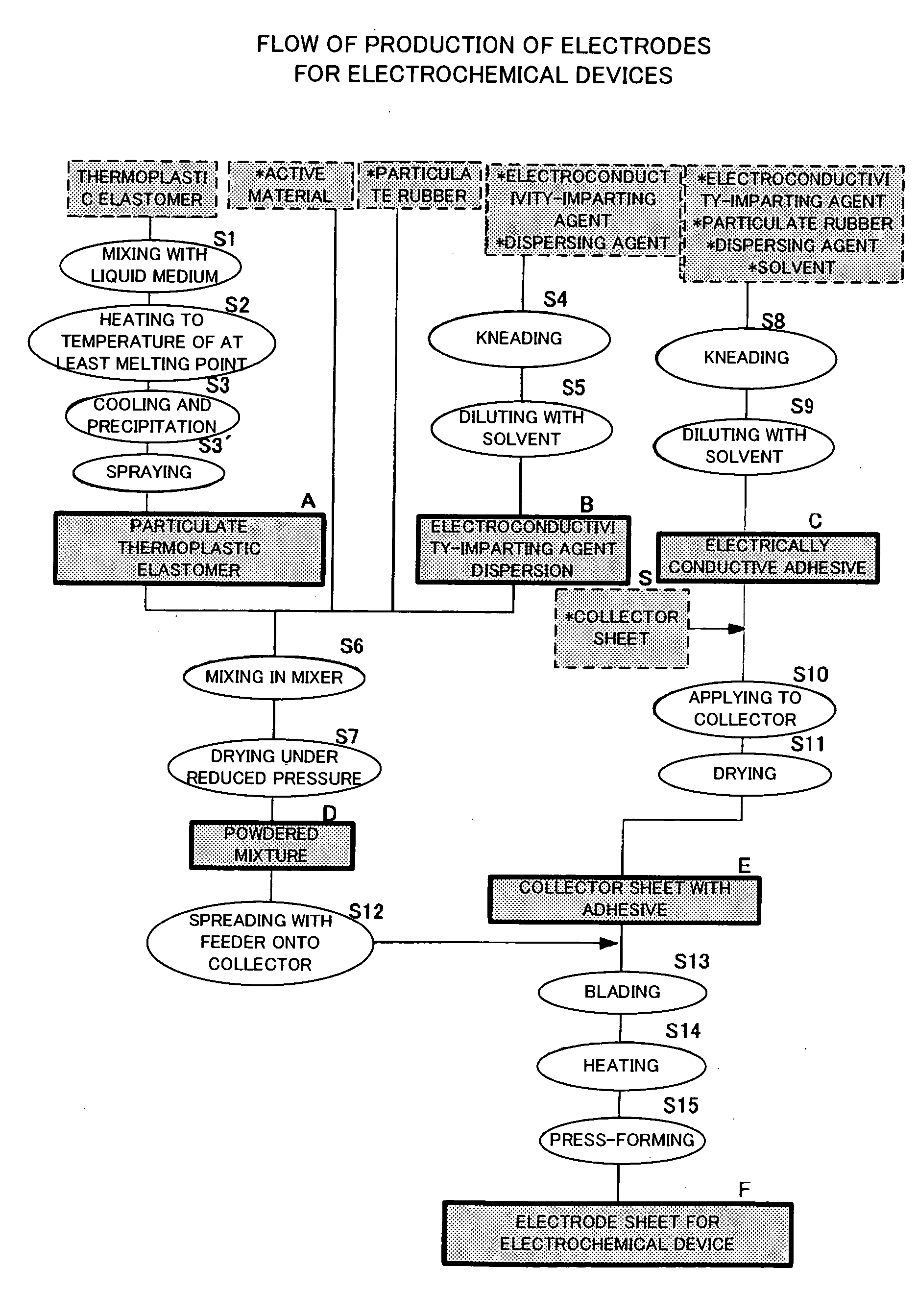

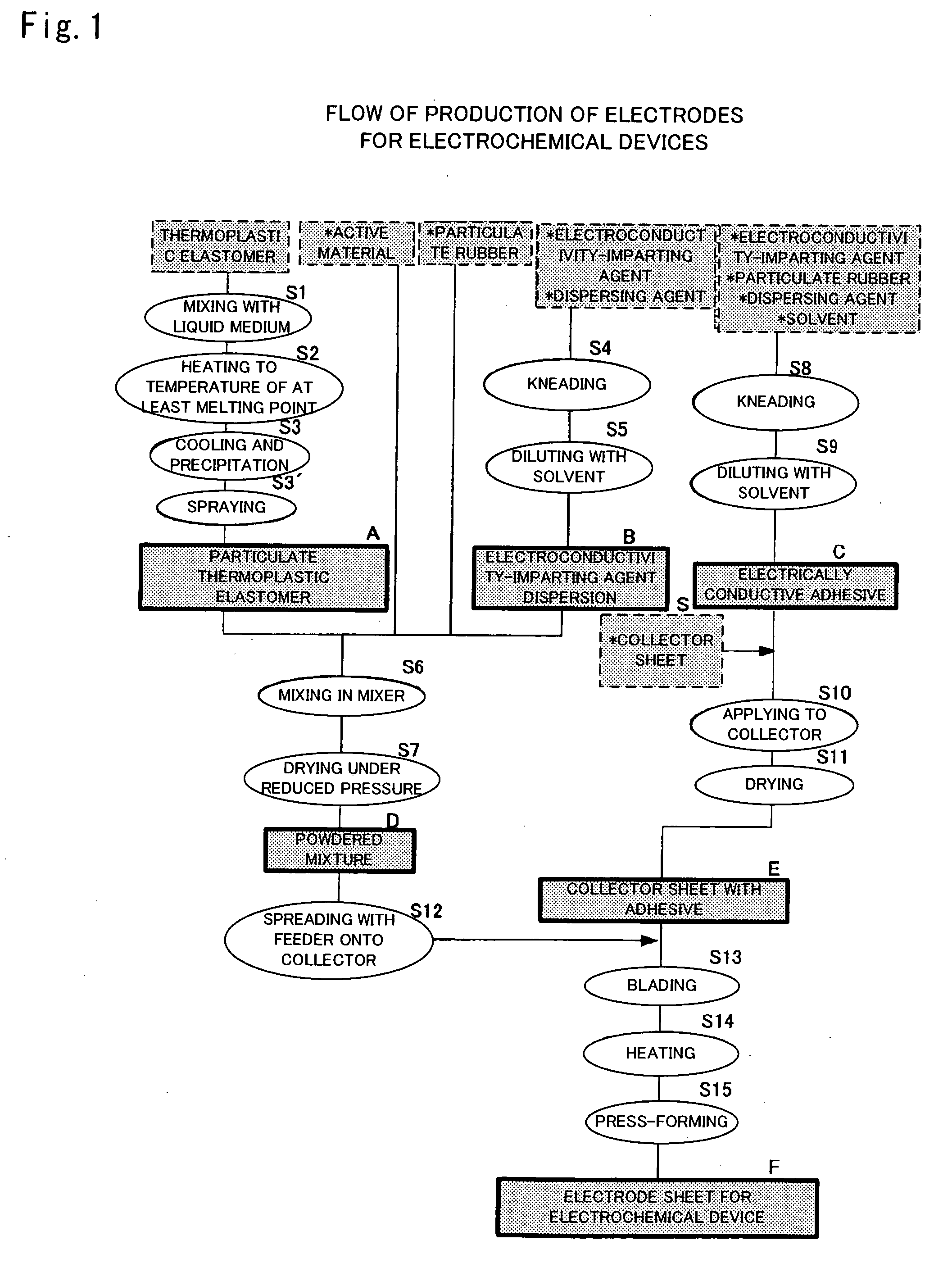

Method used

Image

Examples

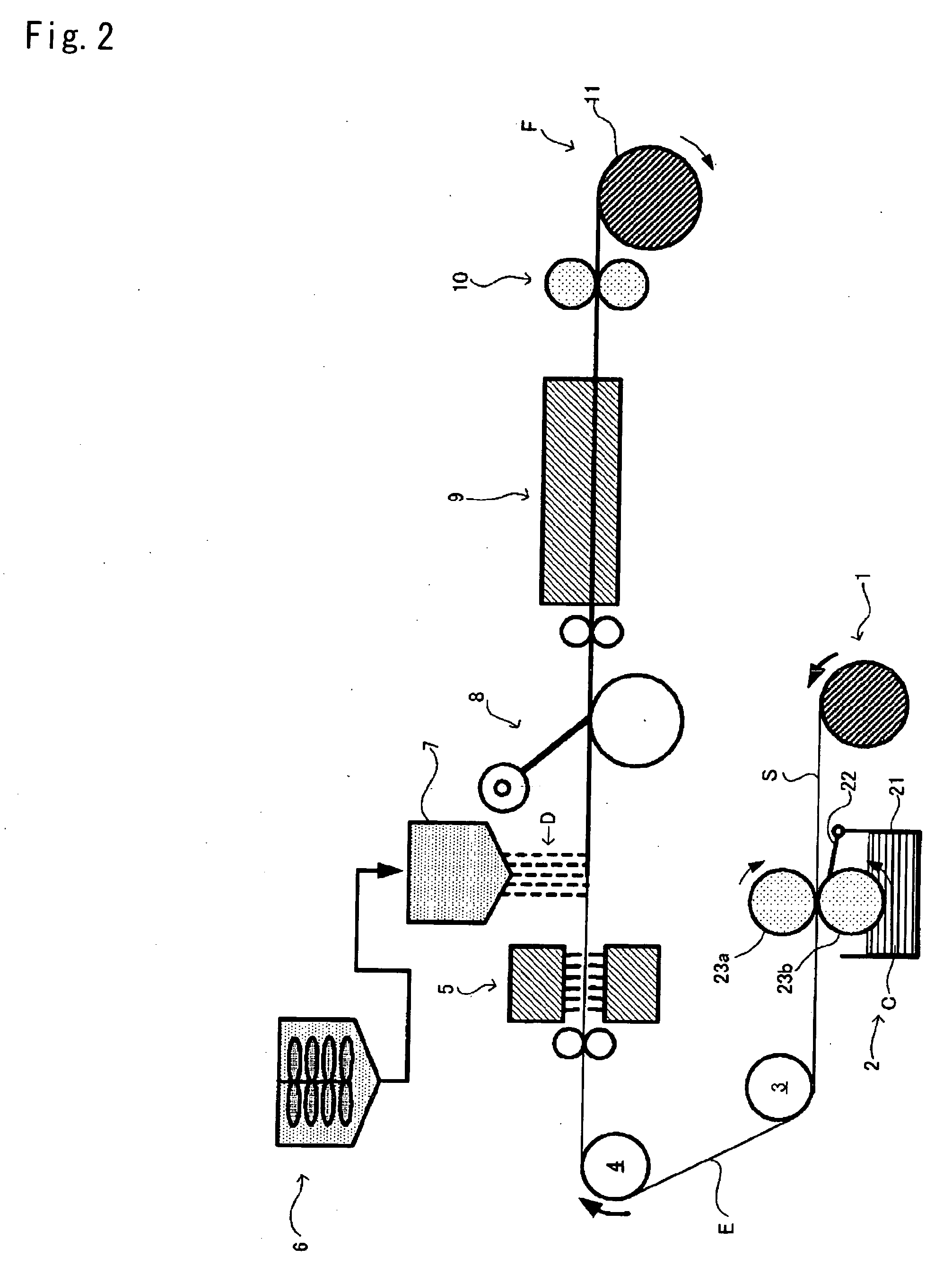

example 1

[0083] In a kneader, 75 parts of a high-purity activated carbon powder with a specific surface area of 1500 m2 / g and an average particle diameter of 10 μm, 16.7 parts of electroconductivity-imparting agent dispersion B, 12.5 parts of particulate rubber of 40% carboxy-modified styrene / butadiene copolymer latex (BM-400B), and 2 parts of particulate thermoplastic elastomer A were kneaded, and then dried under reduced pressure to be powdered. The resulting powdered mixture had an average particle diameter of 15 μm. After drying, electrically conductive adhesive C was applied with a thickness of 5 μm to the collector. The powdered mixture was spread onto the adhesive-coated collector using a screw feeder and allowed to pass through a roll to have an even surface (at a collector sheet feeding speed of 4 m / minute). The collector with the spread powdered mixture was then heated to 200° C. so that the thermoplastic elastomer was melted. Thereafter, the collector with the mixture was roll-pre...

example 2

[0087] A capacitor electrode sheet and an electric double layer capacitor were prepared and subjected to measurement using the process of Example 1 except that 12.5 parts of particulate rubber of 40% acrylate latex (composition: 2-ethylhexyl acrylate / acrylonitrile / methacrylic acid / ethylene glycol dimethacrylate=81 / 15 / 3 / 1 with a particle diameter of 0.15 μm) and 5 parts of particulate thermoplastic elastomer A were alternatively used. It was demonstrated that a long capacitor electrode sheet was stably formed and that the capacitor had good performance. The results are shown in Table 1.

example 3

[0088] A capacitor electrode sheet and an electric double layer capacitor were prepared and subjected to measurement using the process of Example 2 except that 16.7 parts of a polymer dispersion (with a particle diameter of 0.20 μm and a solids content of 30%) was used as the particulate rubber, wherein the polymer dispersion was produced by emulsion polymerization of a monomer mixture of 74 parts of butyl acrylate, 25 parts of methyl methacrylate and 1 part of ethylene glycol dimethacrylate in the presence of 5 parts of polyvinyl alcohol. It was demonstrated that a long capacitor electrode sheet was stably formed and that the capacitor had good performance. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermoplastic | aaaaa | aaaaa |

| energy-density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com