Copper flake powder, method for producing copper flake powder, and conductive paste using copper flake powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

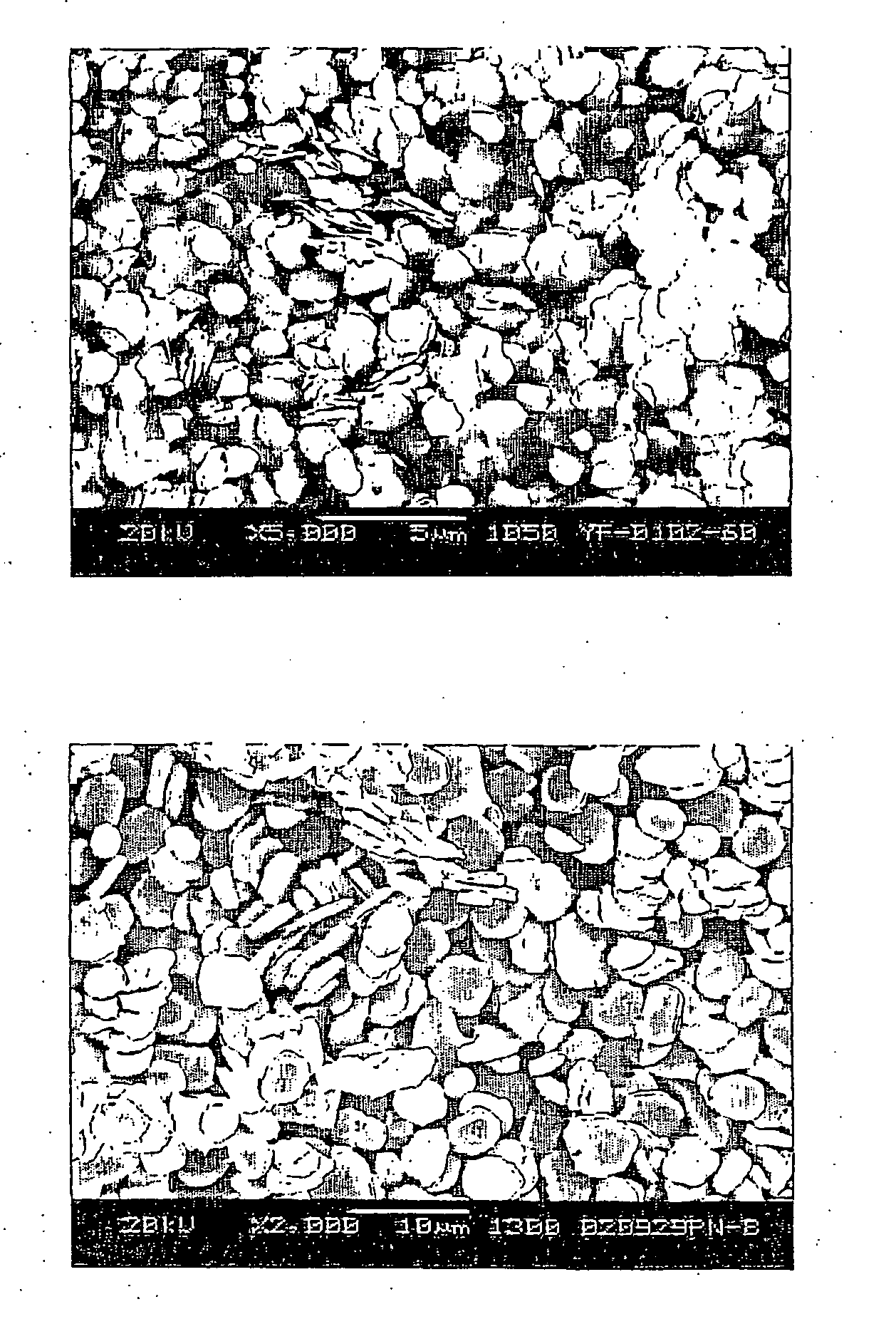

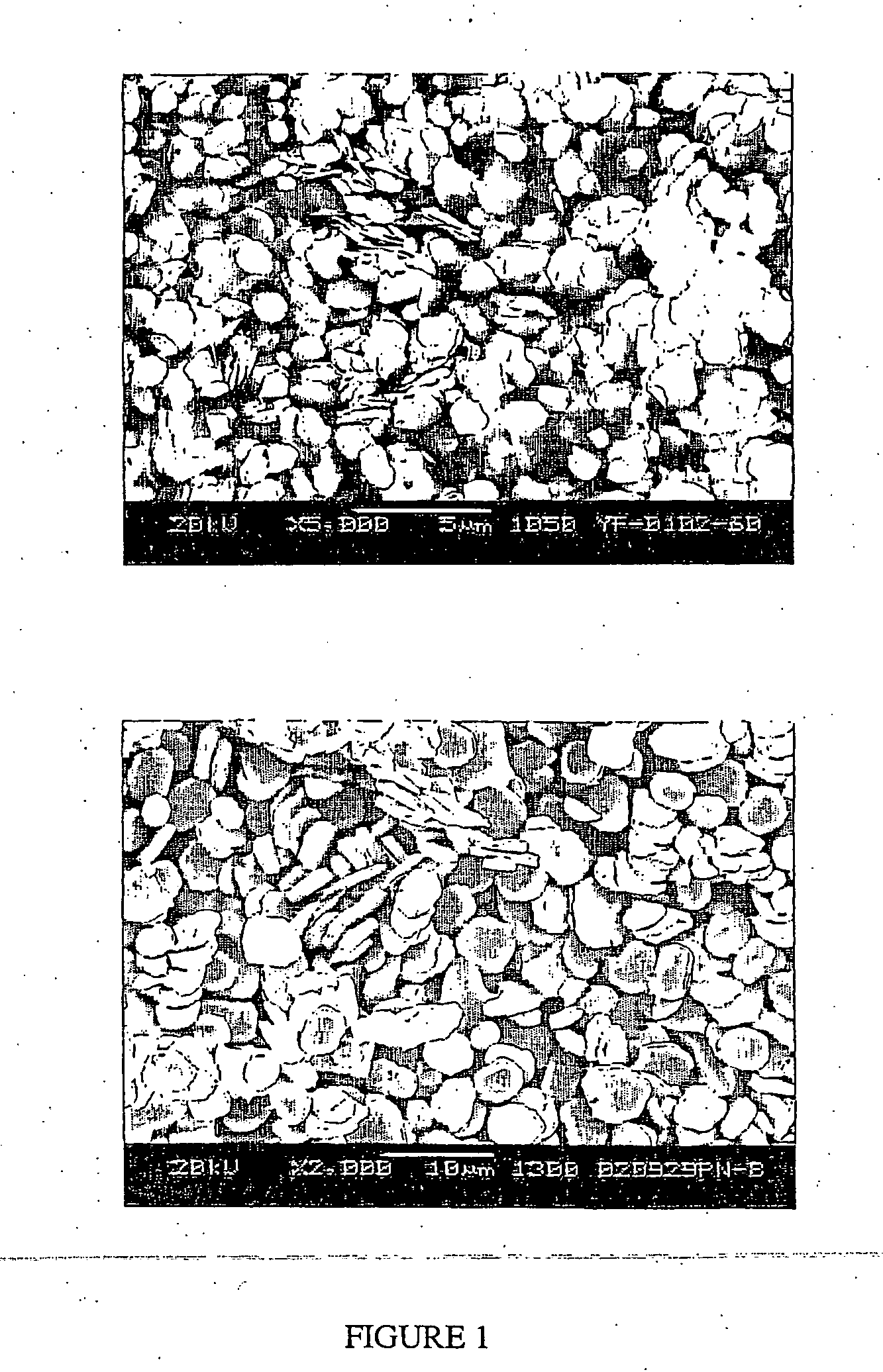

[0040] In this example, copper powder obtained from raw material powder by a below-mentioned method is used, as starting powder for the production process of the present invention to produce flake copper powder.

[0041] The powder properties of the original powder utilized in this example are defined in that, the cumulative particle diameter; D50 was 0.35 μm, which was obtained using a laser diffraction scattering particle size distribution measurement method and average particle diameter; DIA was 0.20 μm obtained by an image analysis. Accordingly, an agglomerate value calculated on D50 / DIA was 1.75.

[0042] The above-mentioned original powder under agglomerate condition was circulated at 6500 rpm, with a Turbo classifier manufactured by Nissei Engineering Limited, which is a commercial pneumatic classification device to perform an operation by which agglomerate particles were made to be singular by colliding the powder particles against each other.

[0043] As a result, the cumulative ...

example 2

[0049] In this example, copper powder obtained from raw material powder with the below-mentioned method was used, as starting powder in a production process of the present invention to produce flake copper powder.

[0050] Powder properties of the original powder utilized in this example are defined in that, the cumulative particle diameter, i.e., D50 value was 0.85 μm, in which the value was obtained using the laser diffraction scattering particle size distribution measurement method, and an average particle diameter, i.e., DIA value was 0.48 μm, which was obtained by image analysis. Accordingly, an agglomerate value calculated based on D50 / DIA value was 1.77.

[0051] With respect to the above-mentioned original particles powder under agglomerate condition, the powder was used in purified water as a copper powder slurry, and then circulated at 3000 rpm, with a fine flow mill manufactured by Pacific Machinery & Engineering Co., Ltd. which is a commercial fluid mill using a centrifugal ...

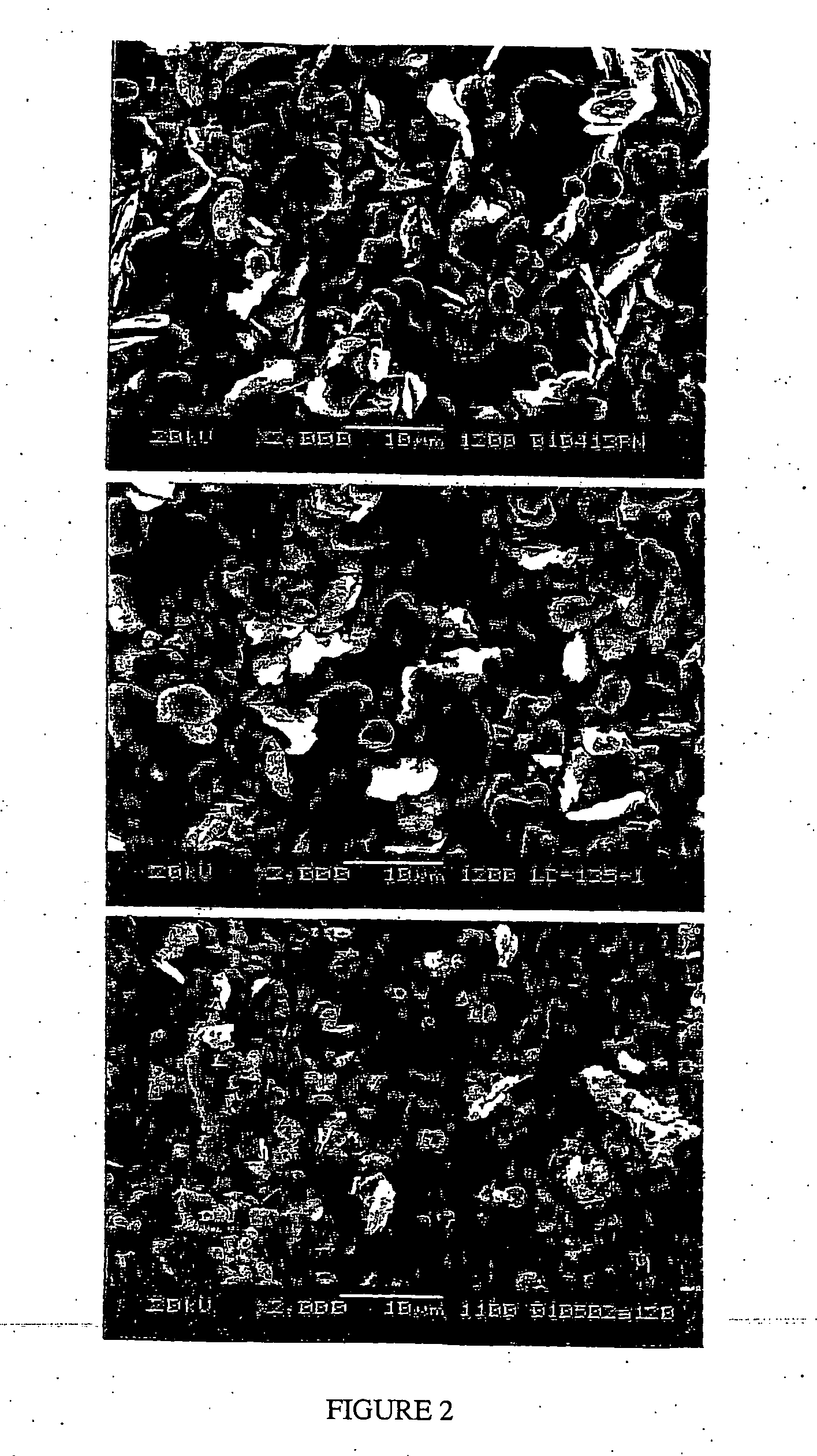

example 3

[0056] In this example, copper powder obtained from raw material powder with a below-mentioned method was used, as starting in a production process of the present invention to produce flake copper powder. The raw material and starting powder utilized in this example were produced in the same way as in Example 2. Therefore, to avoid duplicate explanation about the properties of powder particle and similarly the properties after finishing the treatment, the explanation is omitted.

[0057] Next, 500 g of starting powder constituted by single particles in the same way as in Example 1 were used to compress powder particles of the starting powder and deform them by plastic deformation, so as to obtain from substantially spherical starting powder particles and the flake copper powder. However, in the media dispersion mill called the DISPERMAT D-5226 manufactured by VMG-GETAMANN used the processing time was only changed from Example 1 to 7 hours in this treatment. Then the powder particles o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com