Lubricant system for cold forming, process and composition therefor

a technology of cold forming and lubricant, which is applied in the direction of lubricant composition, additives, metal material coating processes, etc., can solve the problems of inability to form or otherwise be practicable, calcium in the coating, and the inability to significantly improve the refinement of grain refinement, so as to improve the adhesion the life of the second lubricant bath, the effect of low calcium conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Specimens: 4″×6″ steel panels, 4130 alloy

Phosphate Bath 1 Preparation:

[0068] Into 75 gallons of water were mixed 150 pounds of Phosphate Makeup Mix 1 containing the components listed in Table A measured in weight percent:

TABLE APhosphate Makeup Mix 1ComponentWt %Zinc Oxide8.75067% Nitric Acid (aq)11.31075% Phosphoric Acid (aq)21.10014% Nickel Nitrate (aq)0.230Hydroxylamine Sulfate0.600(powder)Waterbalance

and 70 pounds of calcium nitrate. Sufficient water to make 100 gallons of working solution was then mixed in. Sufficient heat was added to bring the bath to the operation temperature. Total Acid=34.8, Free Acid=5.9

Specimen Coating Processes:

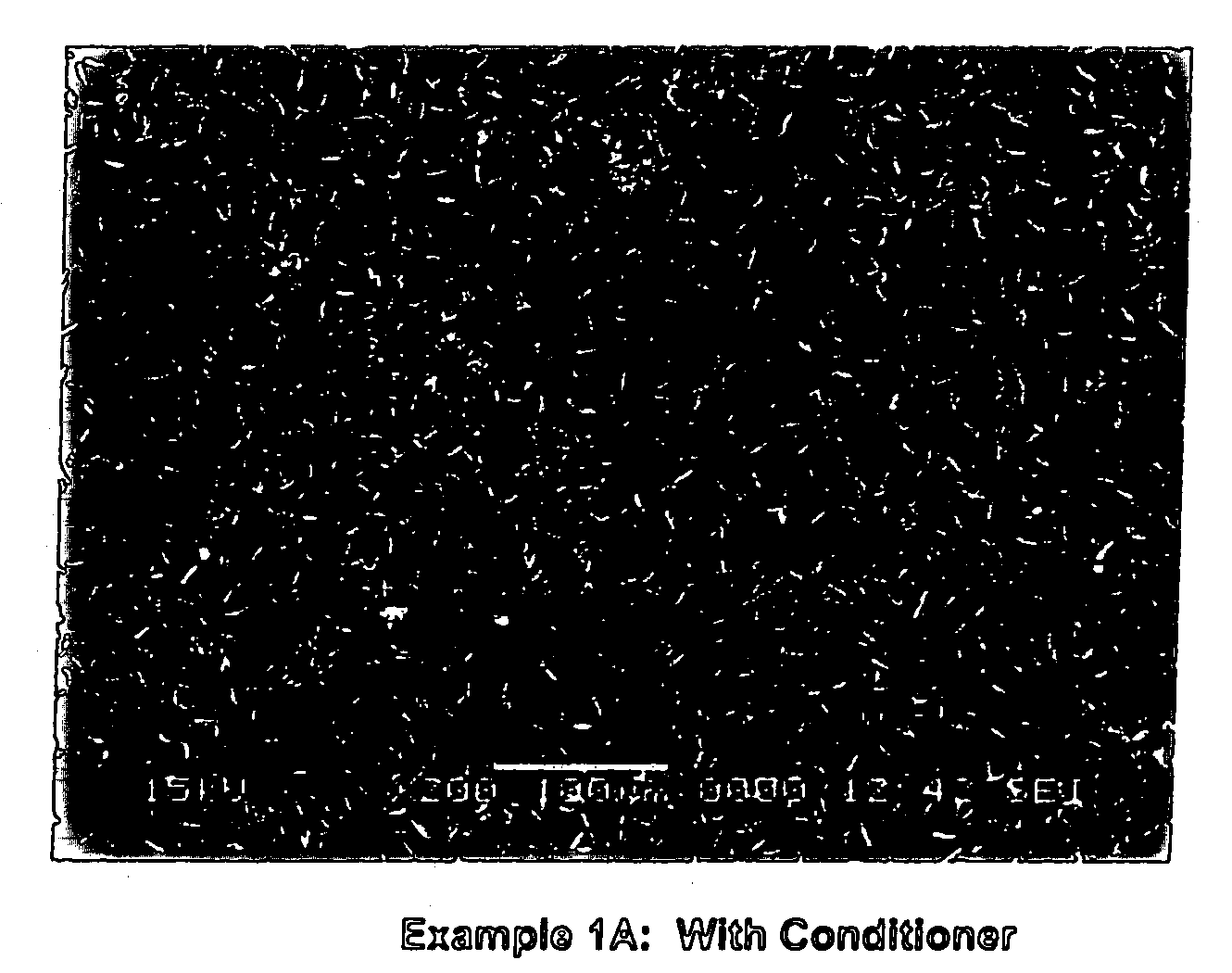

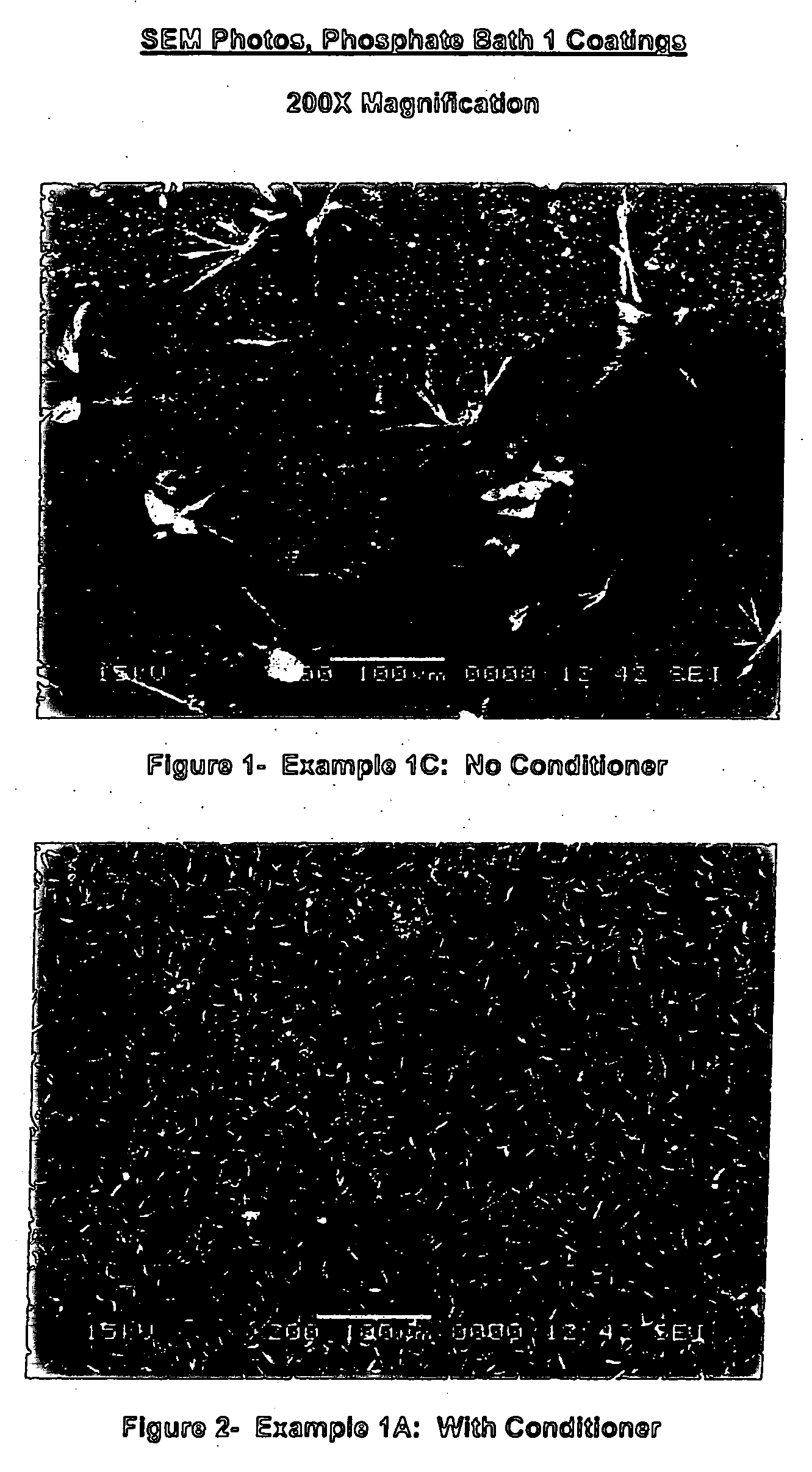

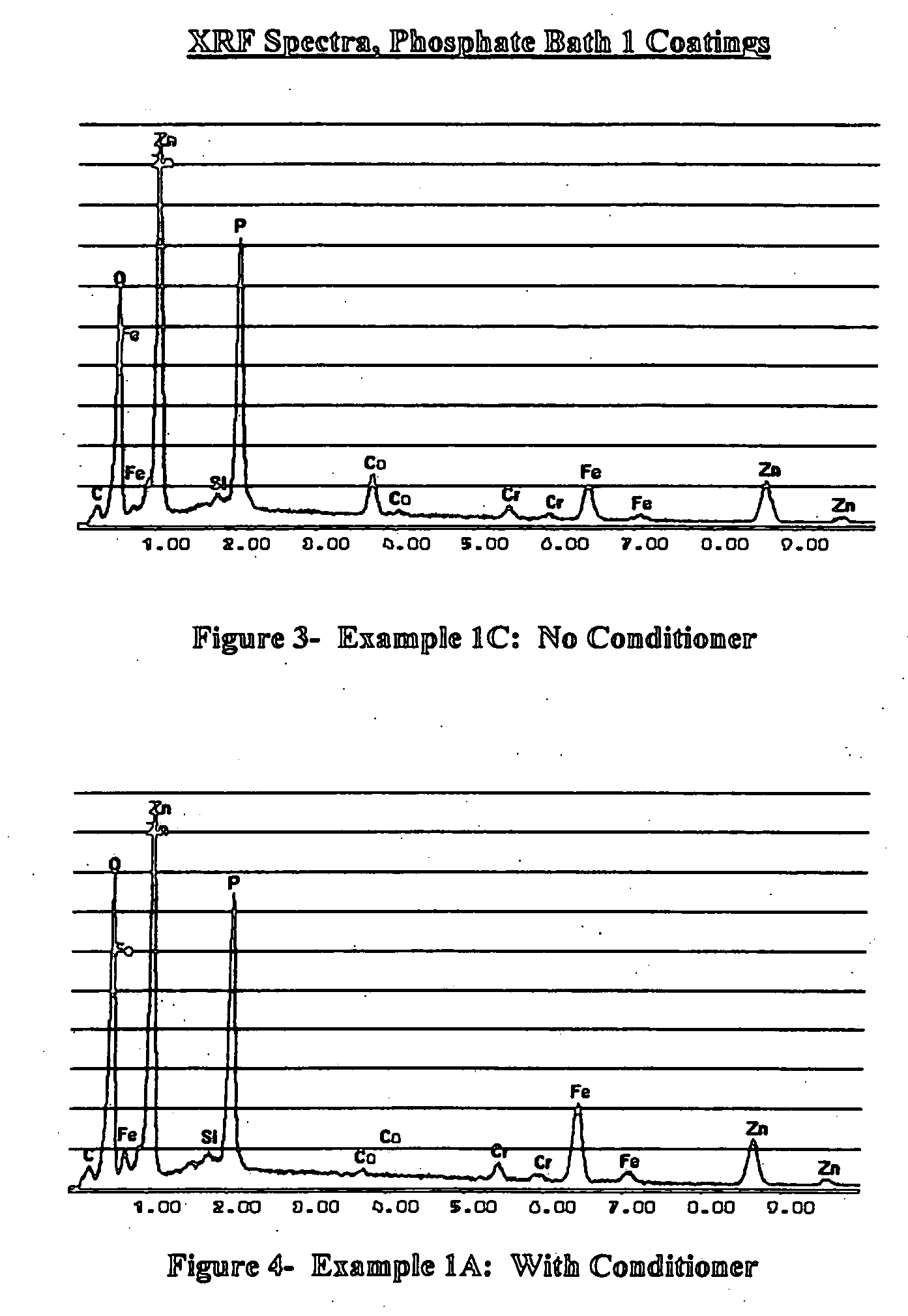

example 1a

[0069] With Conditioner. “Phosphate Only”. The specimen was treated according to the following: [0070] 1. Clean: Parco Cleaner 2077X, a commercial aqueous alkaline cleaner available from Henkel Corporation, 4 oz / gal, 180° F., 5 minutes [0071] 2. Hot Water Rinse: approx. 130° F., 1 min [0072] 3. Pickle: 10% v / v concentrated sulfuric acid inhibited with Rodine 195@0.25% v / v of concentrated acid used (i.e., 0.25% of 10%=0.025% v / v of working pickle) [0073] 4. Cold Water Rinse: approx 60-70° F., 30 seconds [0074] 5. Conditioner: Fixodine Z (nominal Ti 1-10 wt %), a commercial titanium salt containing conditioner available from Henkel Corporation, 1 g / L, 125° F., 1 min [0075] 6. Phosphate: Phosphate Bath 1, 180° F., 5 min [0076] 7. Cold Water Rinse [0077] 8. Forced Air Dry Off

example 1b

[0078] With Conditioner, “Phosphate+Lube”. The specimen was treated as in Steps 1-7 of Example 1A, followed by: [0079] 8. Bonderlube 234, a commercial aqueous sodium stearate lubricant available from Henkel Corporation 60 g / L, 180° F., 5 min. [0080] 9. Bake: 212° F., 5 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com