Structure and process to fabricate lead overlay (LOL) on the bottom spin valve

a technology of lead overlay and bottom spin valve, which is applied in the field of fabrication of giant magnetoresistive (gmr) magnetic field sensor of the bottom spin valve, can solve the problems of narrow trackwidth design, reduced signal amplitude and sensor stability, and almost impossible to avoid shorting between lol edges, etc., to enhance the signal strength produced by the sensor and reduce resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

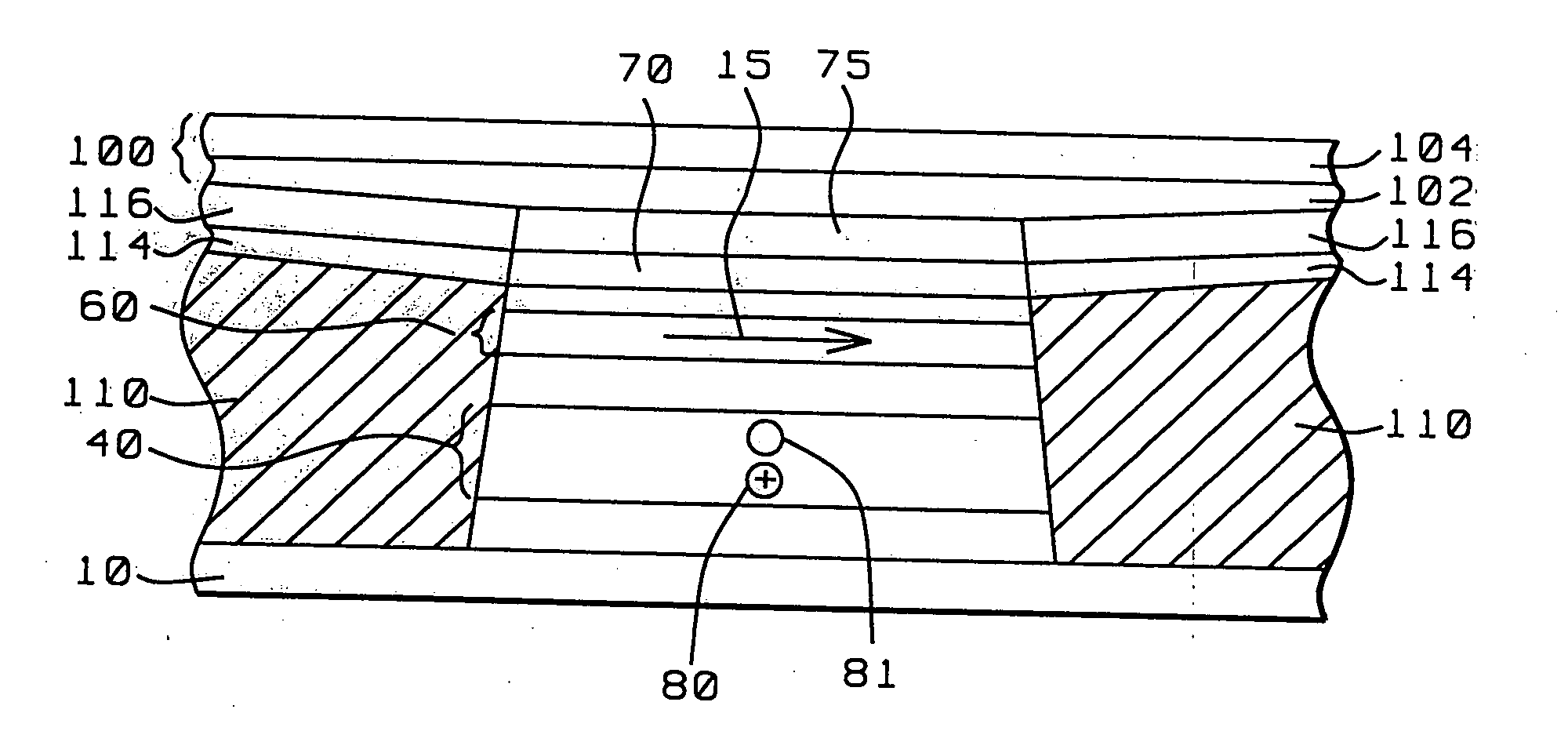

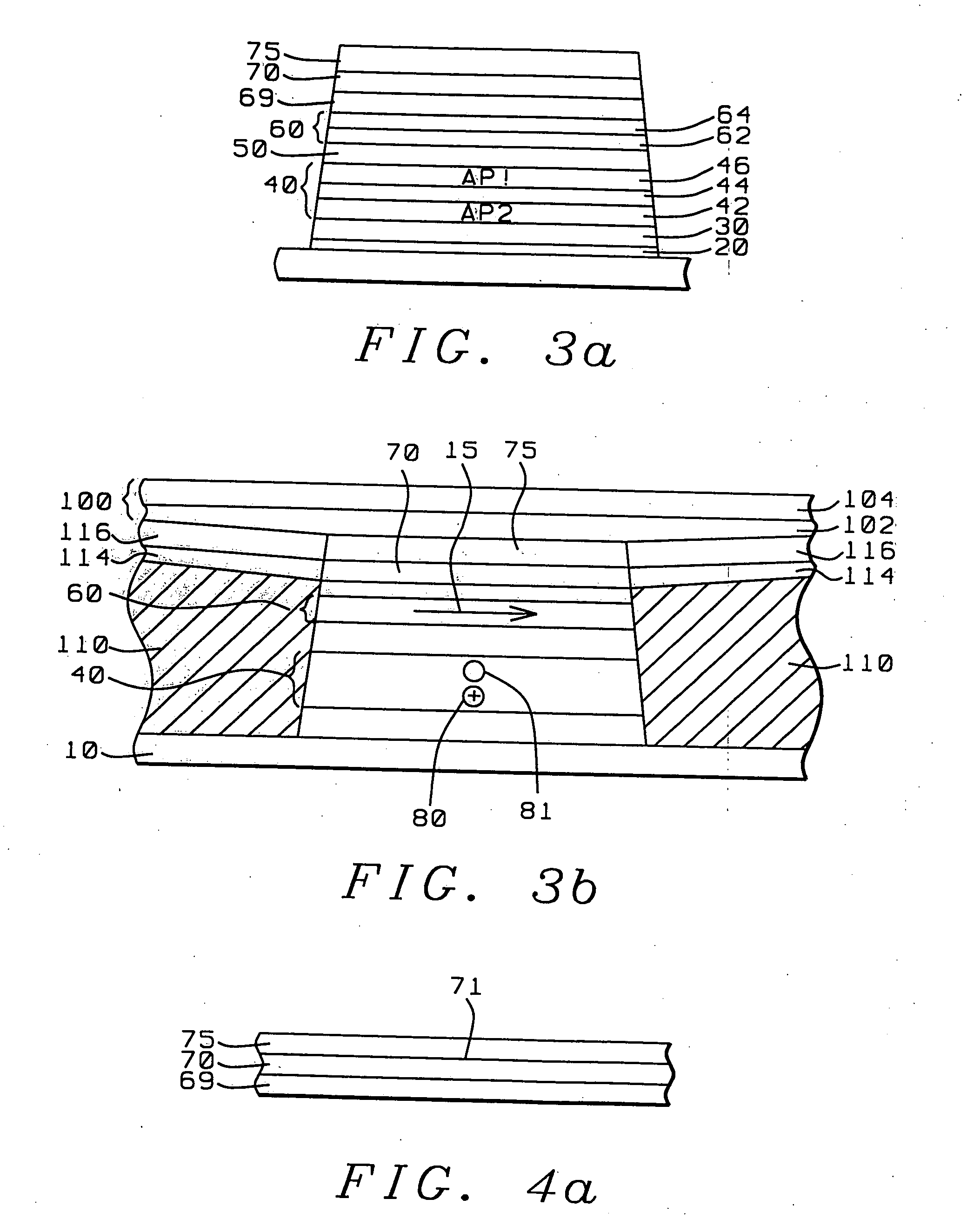

[0022] Referring first to FIG. 3a there is shown a schematic cross-sectional view through an ABS plane of a bottom spin valve (BSV) GMR sensor stack subsequent to a first annealing process but before the formation of a contiguous longitudinal hard bias layer and blanket LOL layer. The stack is formed in accord with the preferred embodiment of the present invention.

[0023] Moving vertically upward in the stack structure, on the substrate (10) there is first seen a seed layer (20), which is typically a structure enhancing layer of NiCr and which is typically formed to a thickness of between approximately 50 and 65 angstroms, with approximately 60 angstroms being preferred. On the seed layer there is then formed a pinning layer (30) of antiferromagnetic material, typically MnPt, formed to a thickness of between approximately 100 and 150 angstroms, with approximately 120 angstroms being preferred. On the pinning layer there is then formed a pinned layer (40), which, in this embodiment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com