Methods for making carboxylated pulp fibers

a technology of carboxylated pulp fibers and fibers, which is applied in the multi-stage pulping process, organic chemistry, and pulping with inorganic bases. it can solve the problems of fiber strength loss, crosslinking, yellowing, and poor reproduction of the tempo system, and achieves the effect of little additional equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

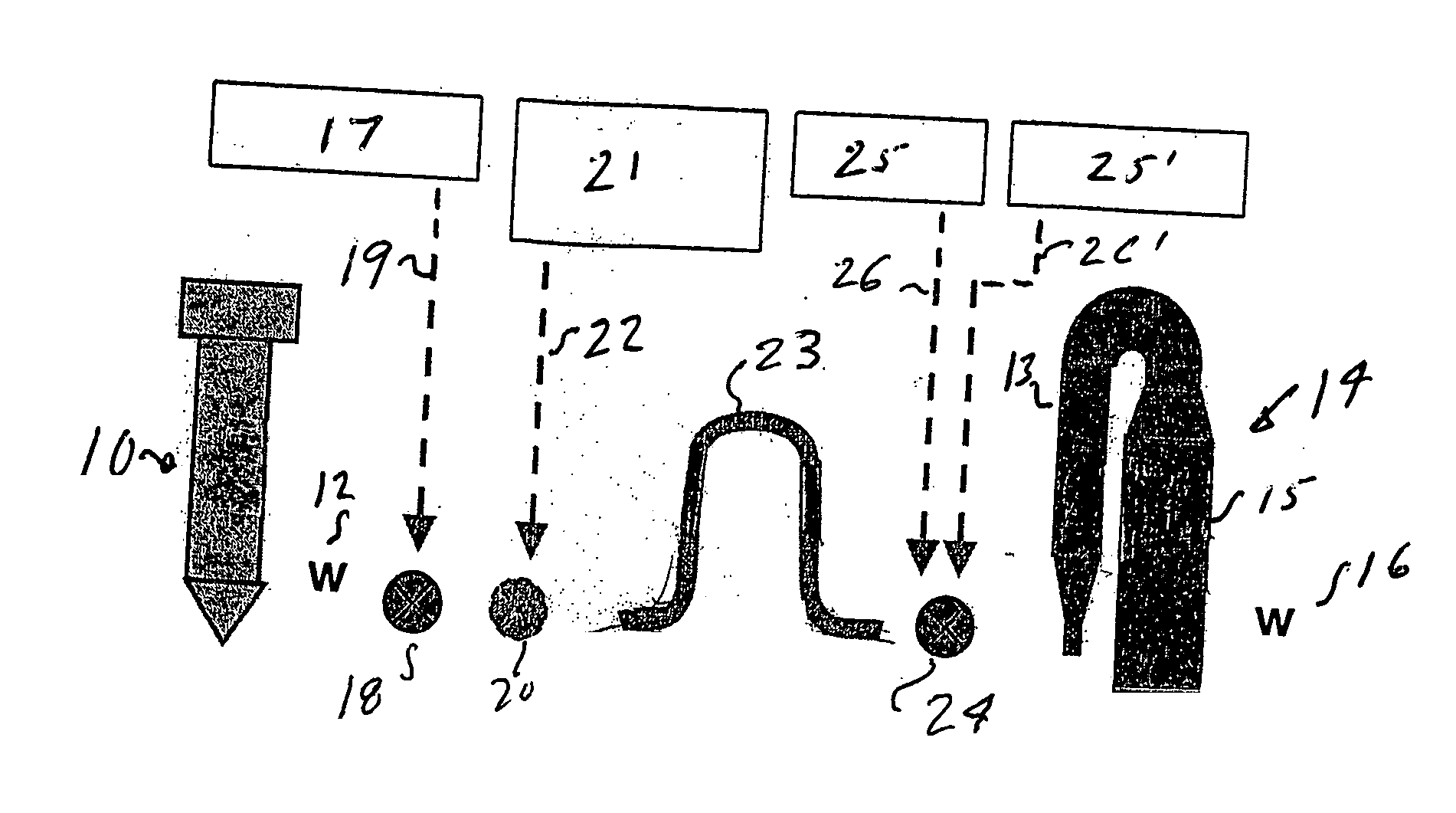

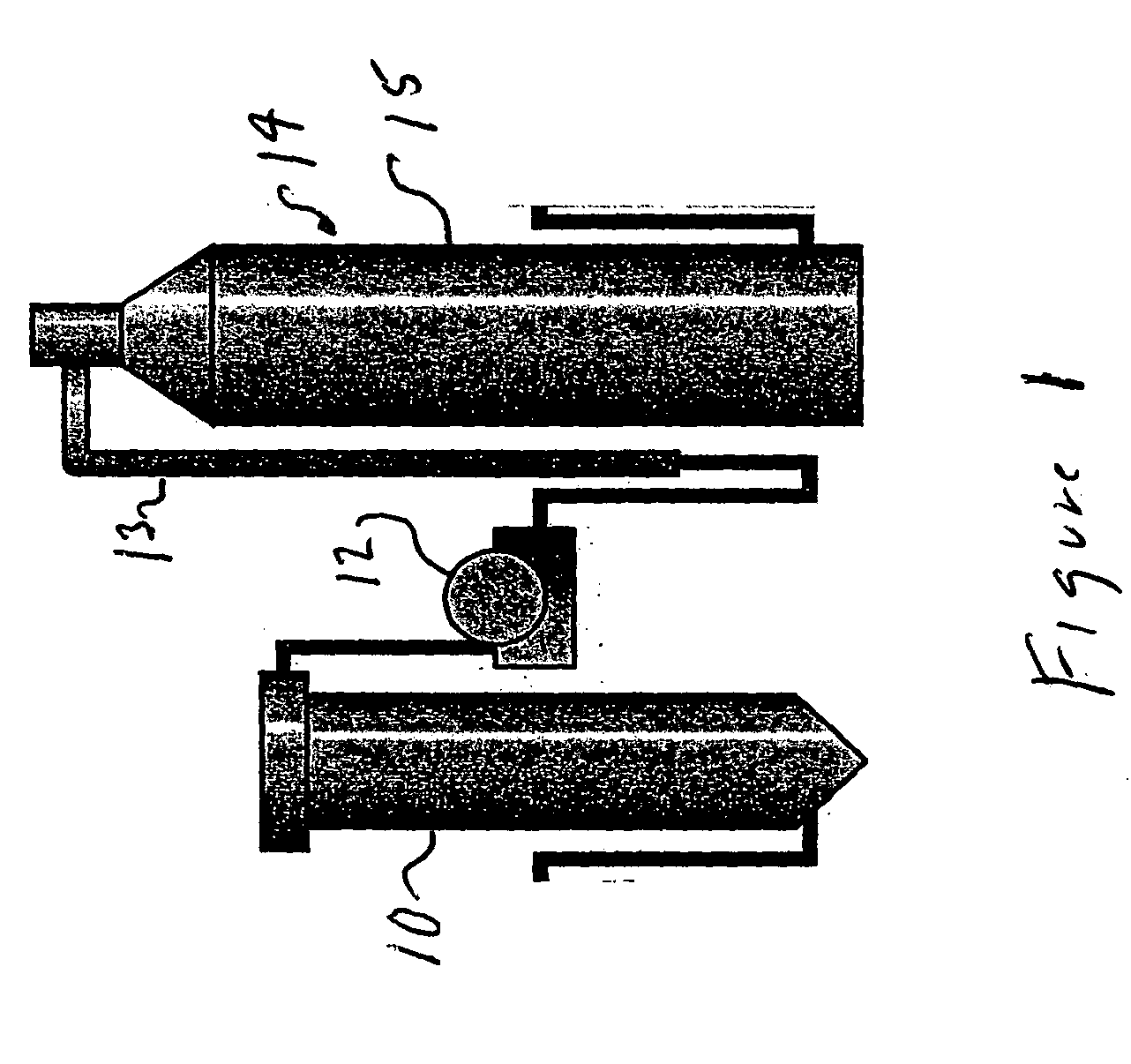

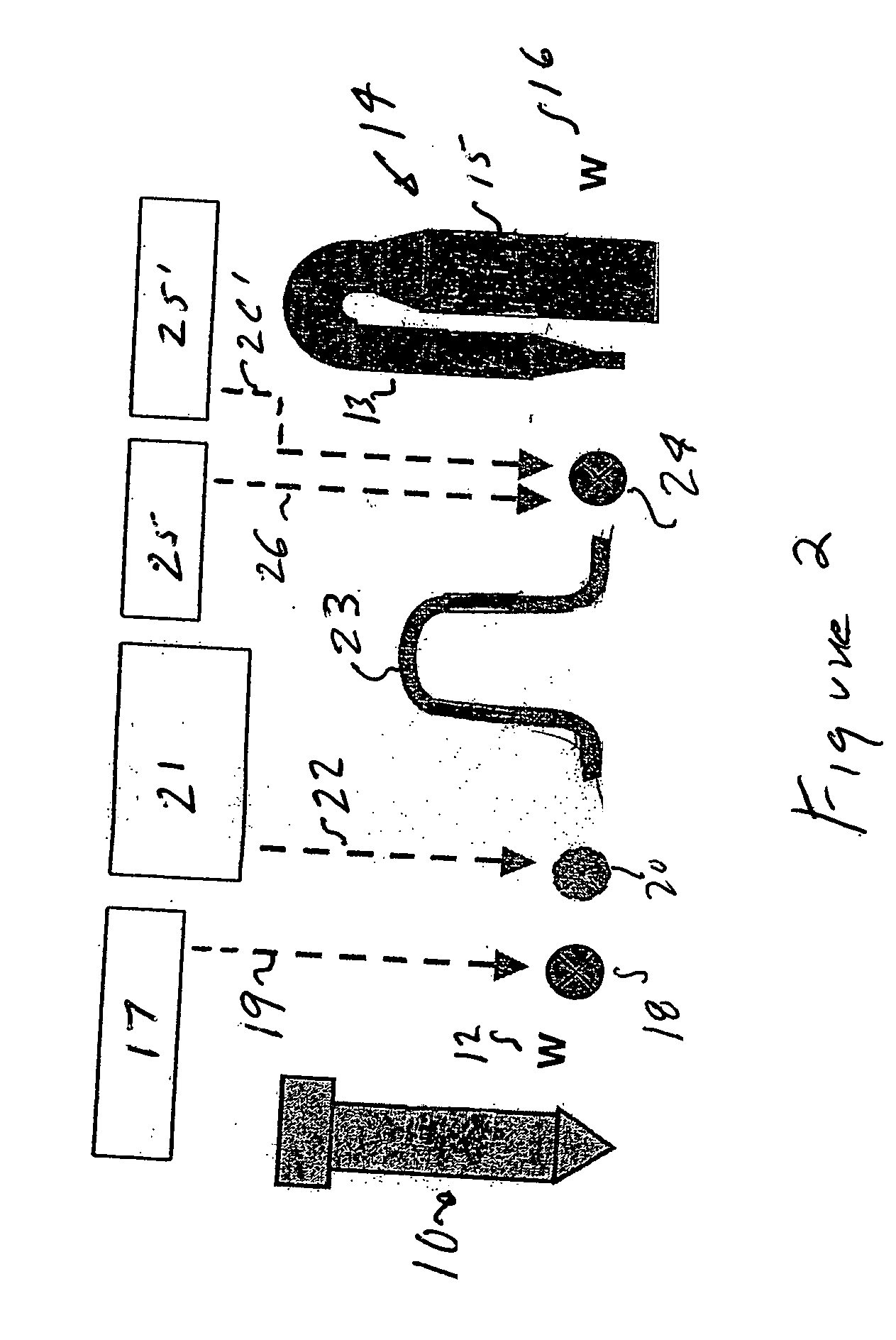

Method used

Image

Examples

example 35

Never-dried partially bleached softwood pulp collected after the E2 bleach stage of the Weyerhaeuser Prince Albert SK mill pulp having an oven dry weight of 60 g, and 9.2 g sodium carbonate was added to 310 g of DI water and the mixture was heated to 70° C. 98 mL of chlorine dioxide, 6.7 g / L, and 1.2 g of ethylene glycol ketal of triacetoneamine (EGK-TAA) were mixed and added to the pulp. The pulp was mixed rapidly by hand. Samples were taken at 15, 30, 60, 120, 180 and 240 seconds after the ClO2 / EGK-TAA solution first contacted the pulp. Each of the samples were placed in a solution of 0.5 g NaBH4 in 100 mL of water and left overnight at room temperature with periodic stirring. The pulps were then tested for carboxyl content. The carboxyl content in meq / 100 g were as follows: 15 seconds-6.7, 30 seconds-6.8, 60 seconds-7.2, 120 ds-7.5, 180 seconds-7.55, 240 seconds-7.6.

example 36

Northern softwood partially bleached kraft pulp collected after the E2 stage of the Weyerhaeuser Prince Albert, SK pulp mill was dewatered to 25-30% solids with a screw press.

All percentages are weight percentages based on the oven dry weight of the pulp.

The pulp was slurried in water and fed to a twin roll press which delivered pulp at a predetermined constant rate of 3.0 kg / minute pulp solids at 8-9% consistency (weight of pulp / weight of water) to a pilot process. Just after the twin roll press, sodium hydroxide was sprayed on the pulp stream at a rate of 0.65%. The pulp slurry was then mixed and heated in a steam mixer and fed to a Seepex progressive cavity pump which provided pulp slurry flow through two high intensity mixers and an upflow tower. The upflow tower fed a downflow tower by gravity. Pulp product was mined from the bottom of the downflow tower, adjusted to pH 7-9 with sodium hydroxide and dewatered on a belt washer.

EGK-TAA was dissolved in water and metered in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reaction time | aaaaa | aaaaa |

| reaction time | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com