Method of preparing methyl catechol using calcium nitrite as raw material

A technology of guaiacol and calcium nitrite, which is applied in the chemical field, can solve the problems of difficult treatment of ferrous sulfate waste liquid, difficulty in separating copper sulfate and sodium sulfate, and reduced catalytic effect of copper sulfate, so as to achieve environmental protection and recycling. Simple and easy to implement, the effect of eliminating waste water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

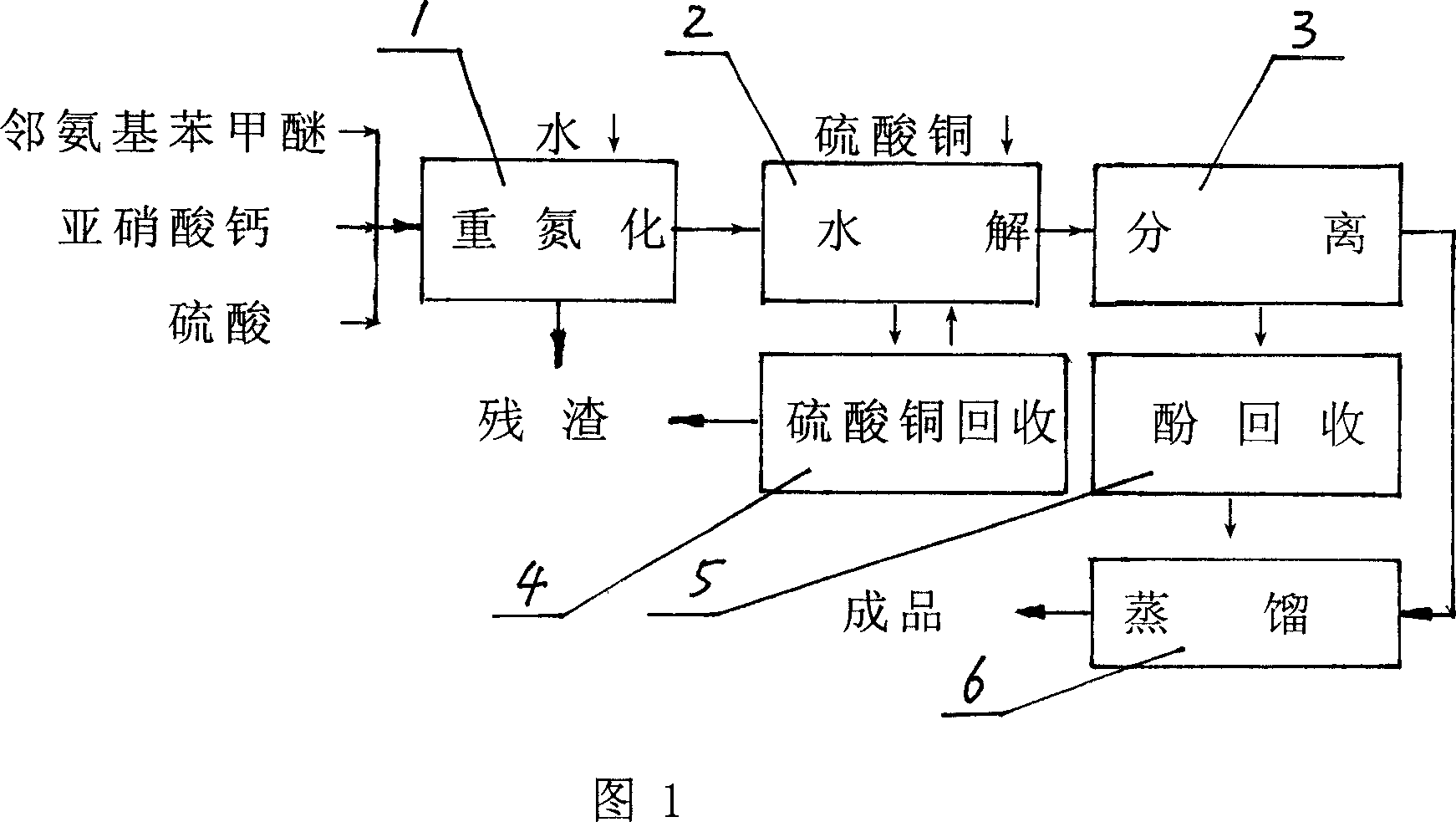

[0021] The present invention will be further described below using the drawings and examples.

[0022] With reference to Fig. 1, the reaction equation of diazotization is:

[0023]

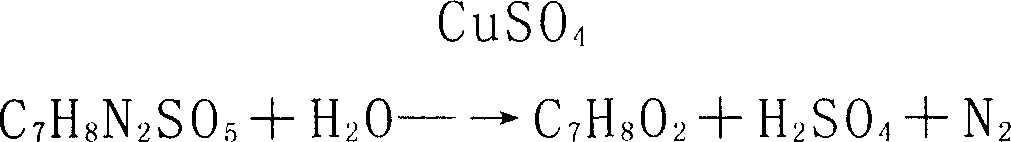

[0024] The reaction equation for hydrolysis is:

[0025]

[0026] Copper sulfate recovery reaction equation is:

[0027]

[0028] With reference to Fig. 1, take calcium nitrite as the method for raw material preparation guaiacol, comprise the following steps successively:

[0029] Diazotization process 1, diazotization process 1 is to add sulfuric acid and water in the diazotization kettle to mix dilute sulfuric acid, add anthranilic ether to the dilute sulfuric acid to neutralize to form methyl ether sulfate, and then add calcium nitrite dropwise The solution is subjected to diazonium reaction, the reaction temperature is 5-10°C, after the reaction reaches the end point, the solid residue is separated through solid-liquid separation, and the clarified diazo solution is sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com