Piercing resistant flashing and manufacture method thereof

A waterproof sheet and puncture-resistant technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of incomplete leakage, inability to prevent building leakage, improper construction and protection, etc., and achieve excellent anti-corrosion Excellent puncture property, low wire expansion, and strong adaptability to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

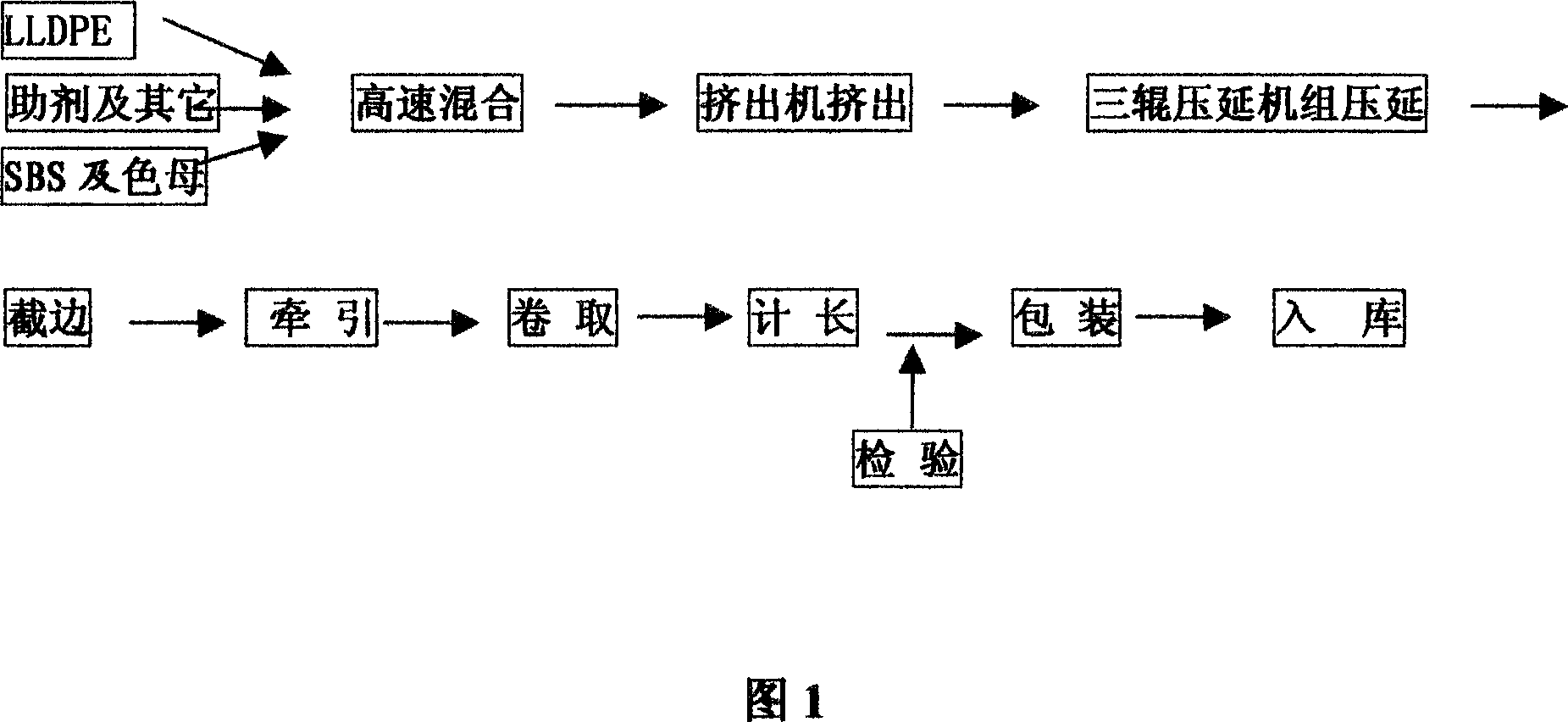

[0027] Recipe and preparation method:

[0028] Linear Low Density Polyethylene 85kg

[0029] Thermoplastic Elastomer SBS 10kg

[0030] Antioxidant 1010 1kg

[0031] Color Masterbatch 3kg

[0032] Light calcium carbonate 3kg

[0033] Measure all the raw materials according to the formula requirements and put them into the high-speed mixer to mix evenly, put them into the hopper of the extruder, and carry out extrusion and calendering according to the process described in the attached drawing of the manual to make LECB waterproof sheet. The processing temperature of each section of extruder barrel and hanger die lip is as follows:

[0034] Cylinder: Zone 1, Zone 2, Zone 3, Zone 4, Zone 5, Zone 6, Zone 7, Flange

[0035] 140°C 150°C 155°C 160°C 165°C 175°C 185°C 175°C

[0036] Hanger die lip: District 1, District 2, District 3, District 4, District 5, District 6, District 7, District 8, District 9

[0037] 195°C 190°C 185°C 180°C 180°C 185°C 185°C 190°C 195...

Embodiment 2

[0040] HDPE 85kg

[0041] Thermoplastic Elastomer SBS 6kg

[0042] UV absorber UV531 4kg

[0043] Color Masterbatch 3kg

[0044] Light calcium carbonate 2kg

[0045] The preparation method is the same as in Example 1.

Embodiment 3

[0047] Linear Low Density Polyethylene 85kg

[0048] Thermoplastic Elastomer SBS 10kg

[0049] Antioxidant 1010 2kg

[0050] Color Masterbatch 3kg

[0051] Light calcium carbonate 8kg

[0052] The preparation method is exactly the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com