High-pressure thin-wall large-diameter extrusion oil tank

A technology with large diameter and fuel tank, applied in the field of launch vehicle servo system, can solve problems such as large wall thickness of fuel tank cylinder, achieve good sealing effect, strong adaptability to cylinder deformation, and avoid cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

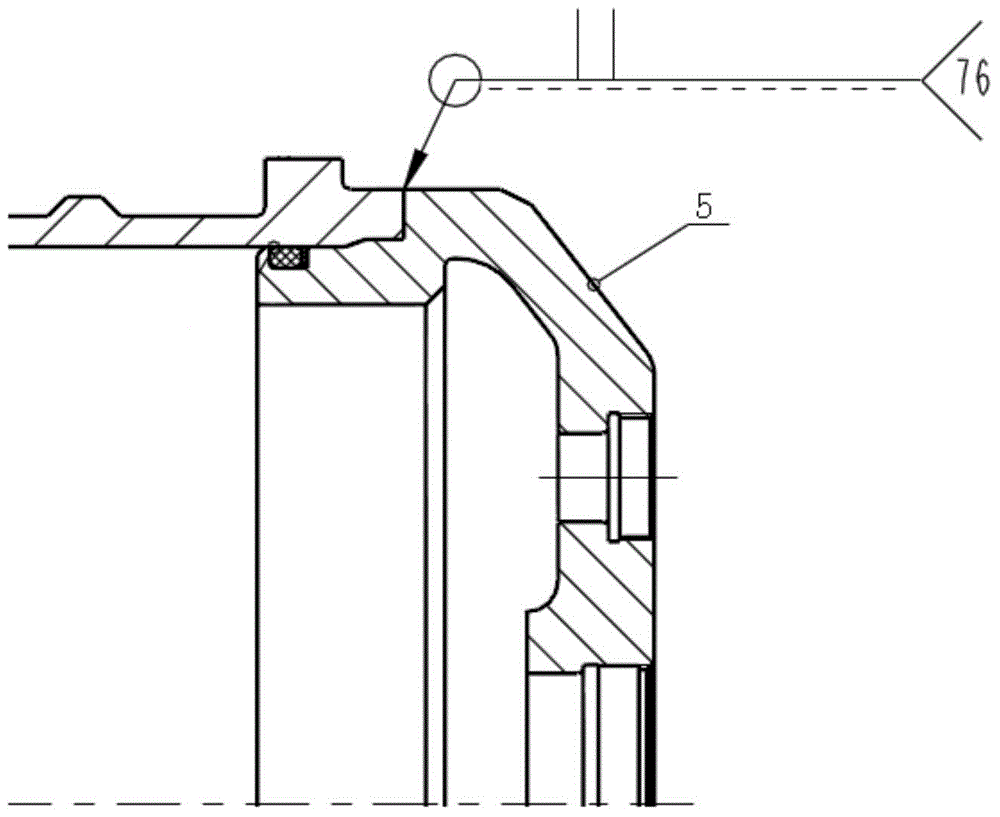

[0019] The invention provides an extruding oil tank which is used in a cold air extruding servo system. The extruded oil tank is specially developed for a cold air extruded servo system. The rated working pressure of the oil tank is 24MPa. According to the working characteristics of the extruded oil tank, the technical scheme of the piston oil tank is adopted. Due to the limited space on the arrow, the diameter of the fuel tank is relatively large, with an inner diameter of 290mm, but the wall thickness is very thin, only 8mm. The medium that needs to be isolated from oil and gas in the fuel tank is helium and aviation hydraulic oil. The helium gas molecule is small, and the sealing is more difficult, and the piston fuel tank must work under high vibration and impact levels, which puts forward higher requirements for sealing. Therefore, squee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com