Heat-reflective interior wall coating

A technology for interior wall coatings and heat reflection, applied in the direction of reflection/signal coatings, epoxy resin coatings, antifouling/underwater coatings, etc., can solve the problems of unreachable, easily brittle mechanical properties, and heat insulation effects of hollow microbeads Poor and other problems, to achieve the effect of good elasticity, excellent heat insulation effect, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

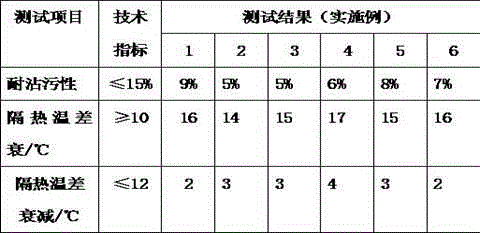

Examples

Embodiment 1

[0020] The heat-reflecting interior wall coating of the present invention comprises the following components in parts by weight: 30 parts of epoxy resin, 15 parts of polyacrylamide, 20 parts of solid ceramic microspheres, 15 parts of solid glass microspheres, and 10 parts of nano heavy calcium , 3 parts of aluminate coupling agent, 7 parts of polyoxyethylene alkylphenol ether, 1 part of polyvinylpyrrolidone, 9 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, and 1 part of fumed silica.

Embodiment 2

[0022] The heat-reflecting interior wall paint of the present invention comprises the following components in parts by weight: 40 parts of epoxy resin, 25 parts of polyacrylamide, 10 parts of solid ceramic microspheres, 5 parts of solid glass microspheres, 1 part of nano-bentonite, 8 parts of silane coupling agent, 2 parts of polyoxyethylene fatty alcohol ether, 5 parts of polyethylene oxide, 3 parts of polyoxyethylene polyoxypropanolamine ether, and 8 parts of polyolefin wax.

Embodiment 3

[0024] The heat-reflecting interior wall paint of the present invention comprises the following components in parts by weight: 35 parts of epoxy resin, 20 parts of polyacrylamide, 15 parts of solid ceramic microspheres, 9 parts of solid glass microspheres, and 6 parts of nanometer mica powder , 6 parts of titanate coupling agent, 4 parts of polyoxyethylene polyoxypropylene block copolymer, 3 parts of modified paraffin wax resin, 6 parts of polyoxypropylene glyceryl ether, and 5 parts of polyamide wax.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com