Process for preparing nano capsule phase change material emulsion

A phase change material and nanocapsule technology, applied in the field of preparation of nanocapsule phase change material emulsion, can solve the problems of reduced particle thermal conductivity, reduced fluid stability, high fluid viscosity, high latent heat, reduced pumping resistance, The effect of low fluid viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

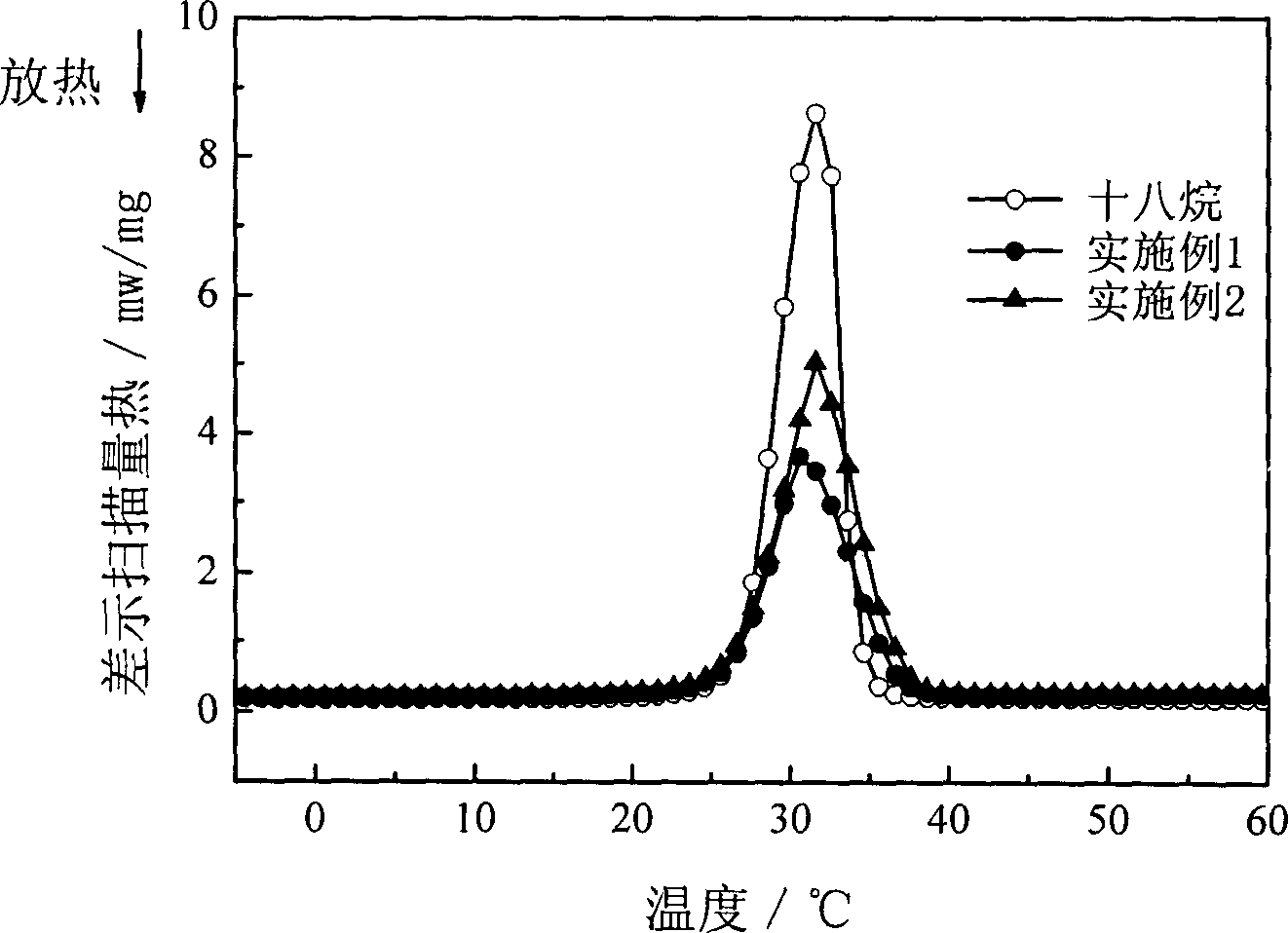

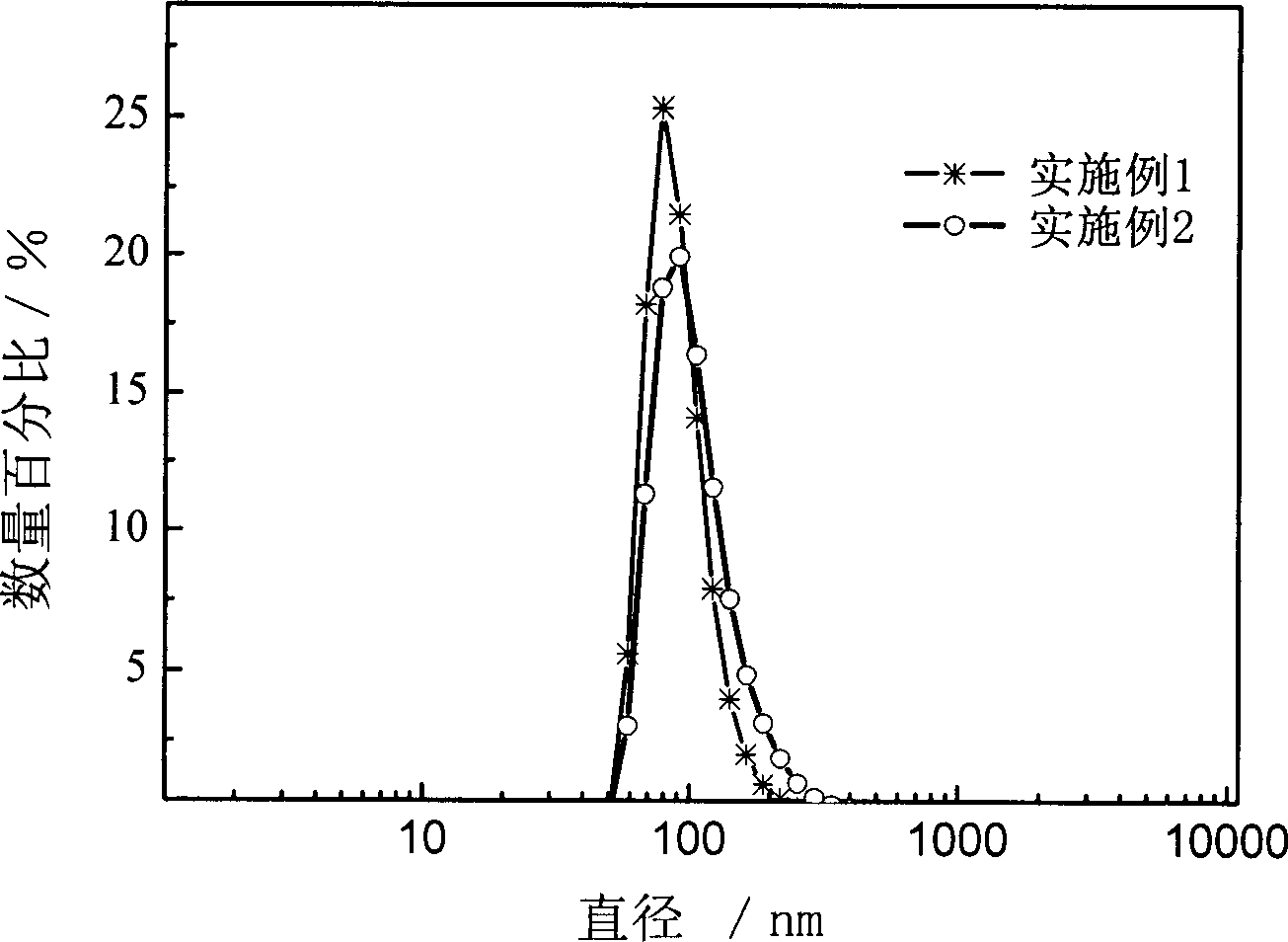

Embodiment 1

[0026] The oil phase liquid that 30g styrene, 30g melting n-octadecane, 0.9g butyl acrylate, 0.3g azobisisobutyronitrile and 0.4g n-dodecanethiol is made into is added to 1.2g compound emulsifier (SDS : OP-10=1:1) and 240g of deionized water, firstly use mechanical stirring for 10min to obtain emulsion, then use ultrasonic cell pulverizer to ultrasonically obtain microemulsion for 15min. Transfer the microemulsion into a 500ml four-neck flask equipped with a reflux tube, nitrogen inlet, mechanical stirring, and a feed port, first stir and pass nitrogen for 30 minutes to remove oxygen from the system, and then heat up to 65°C in a constant temperature water bath under the condensation of the reflux tube The polymerization reaction was carried out for 5 hours, and the nanocapsule phase change material was prepared by naturally cooling to room temperature after the reaction was completed.

Embodiment 2

[0028] 30g of styrene, 45g of molten n-octadecane, 1.2g of acrylic acid, 0.4g of azobisisobutyronitrile and 0.6g of n-dodecanethiol were made into an oil phase liquid, and added to a solution composed of 1.2g of SDS and 240g of deionized water In the process, the emulsion was first obtained by mechanical stirring for 10 minutes, and then the microemulsion was obtained by ultrasonic cell pulverizer for 15 minutes. Transfer the microemulsion into a 500ml four-neck flask equipped with a reflux tube, nitrogen inlet, mechanical stirring, and a feed port, first stir and pass nitrogen for 30 minutes to remove oxygen from the system, and then heat up to 65°C in a constant temperature water bath under the condensation of the reflux tube Polymerization was carried out for 5 hours, and after the reaction was completed, it was naturally cooled to room temperature.

Embodiment 3

[0030] Make 30g methyl methacrylate, 40g molten n-eicosane, 0.9g butyl acrylate, and 0.9g n-dodecanethiol to make an oil phase liquid, add 0.6g potassium persulfate, 1.2g SDS and 240g deionized water In the formed solution, the emulsion was first obtained by mechanical stirring for 10 minutes, and then the microemulsion was obtained by supersonicating for 15 minutes with an ultrasonic cell pulverizer. Transfer the microemulsion into a 500ml four-neck flask equipped with a reflux tube, nitrogen inlet, mechanical stirring, and a feed port, first stir and pass nitrogen for 30 minutes to remove oxygen from the system, and then heat up to 65°C in a constant temperature water bath under the condensation of the reflux tube Polymerization was carried out for 5 hours, and after the reaction was completed, it was naturally cooled to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com