Alserin molecular blotting polymer preparing method

A technology of molecular imprinting and polymers, which is applied in the field of bioengineering technology preparation, can solve the problems that the preparation method of reserpine molecular imprinting polymers has not yet been found, and achieve the effect of high selectivity and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

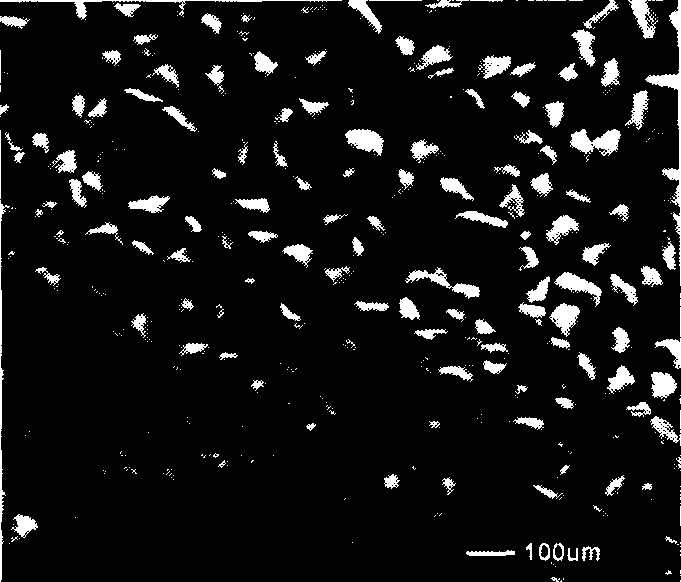

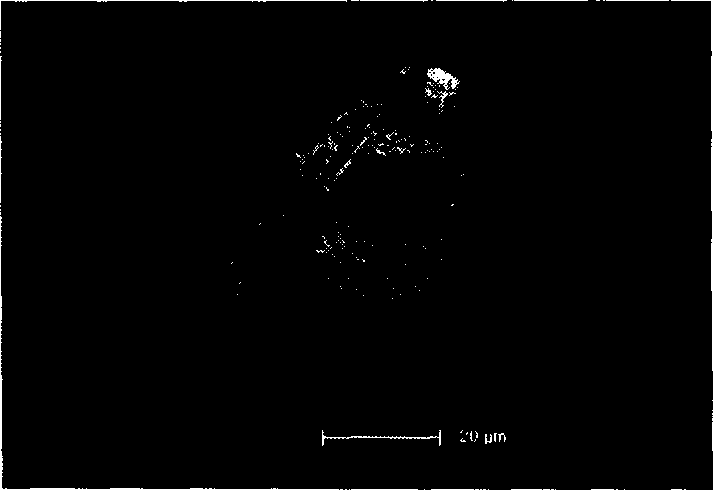

[0031] Dissolve 2 mmol of functional monomer methacrylic acid (MAA) and 1 mmol of template molecule reserpine in 5 ml of porogen chloroform, add 25 mmol of cross-linking agent ethylene glycol dimethacrylate (EGDMA), initiator azobisiso Nitrile (AIBN) ultrasonic degassing for 5 minutes, after mixing evenly, pass nitrogen gas for 10 minutes, and seal under nitrogen state or vacuum state. Reaction at 60°C for 36 hours; after the polymerization reaction, the synthesized polymer was taken out, ground, sieved, and template molecules were removed by Soxhlet extraction with methanol:acetic acid (80:20, V / V), and detected by high-performance liquid chromatography (UV). , until no template molecule is detected; the polymer from which the template molecule has been removed is vacuum-dried (50° C.) for 24 hours, and finally a molecularly imprinted polymer with an average particle size of 25-61 μm is obtained. The inventive effect is as follows: figure 1 , 2 shown.

Embodiment 2

[0033] Dissolve 5 mmol of functional monomer methacrylic acid (MAA) and 1 mmol of template molecule reserpine in 5 ml of porogen chloroform, add 25 mmol of crosslinking agent ethylene glycol dimethacrylate (EGDMA), initiator azobisiso Butyronitrile (AIBN) was ultrasonically degassed for 10 minutes. After mixing evenly, nitrogen gas was introduced for 15 minutes, and sealed under nitrogen or vacuum state. Reaction at 70°C for 20 hours; after the polymerization reaction, the synthesized polymer was taken out, ground, sieved, and template molecules were removed by Soxhlet extraction with methanol:acetic acid (80:20, V / V), and detected by high-performance liquid chromatography (UV). , until no template molecule is detected; the polymer from which the template molecule has been removed is vacuum-dried (50° C.) for 24 hours, and finally a molecularly imprinted polymer with an average particle size of 25-61 μm is obtained, and the inventive effect is basically equivalent to that of f...

Embodiment 3

[0035] Dissolve 8 mmol of functional monomer methacrylic acid (MAA) and 1 mmol of template molecule reserpine in 5 ml of porogen chloroform, add 25 mmol of crosslinking agent ethylene glycol dimethacrylate (EGDMA), initiator azobisiso Butyronitrile (AIBN) was ultrasonically degassed for 10 minutes. After mixing evenly, nitrogen gas was introduced for 15 minutes, and sealed under nitrogen or vacuum state. Reaction at 65°C for 28 hours; after the polymerization reaction, the synthesized polymer was taken out, ground, sieved, and template molecules were removed by Soxhlet extraction with methanol:acetic acid (80:20, V / V), and detected by high-performance liquid chromatography (UV). , until no template molecule is detected; the polymer from which the template molecule has been removed is vacuum-dried (50° C.) for 24 hours, and finally a molecularly imprinted polymer with an average particle size of 25-61 μm is obtained, and the inventive effect is basically equivalent to that of f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com