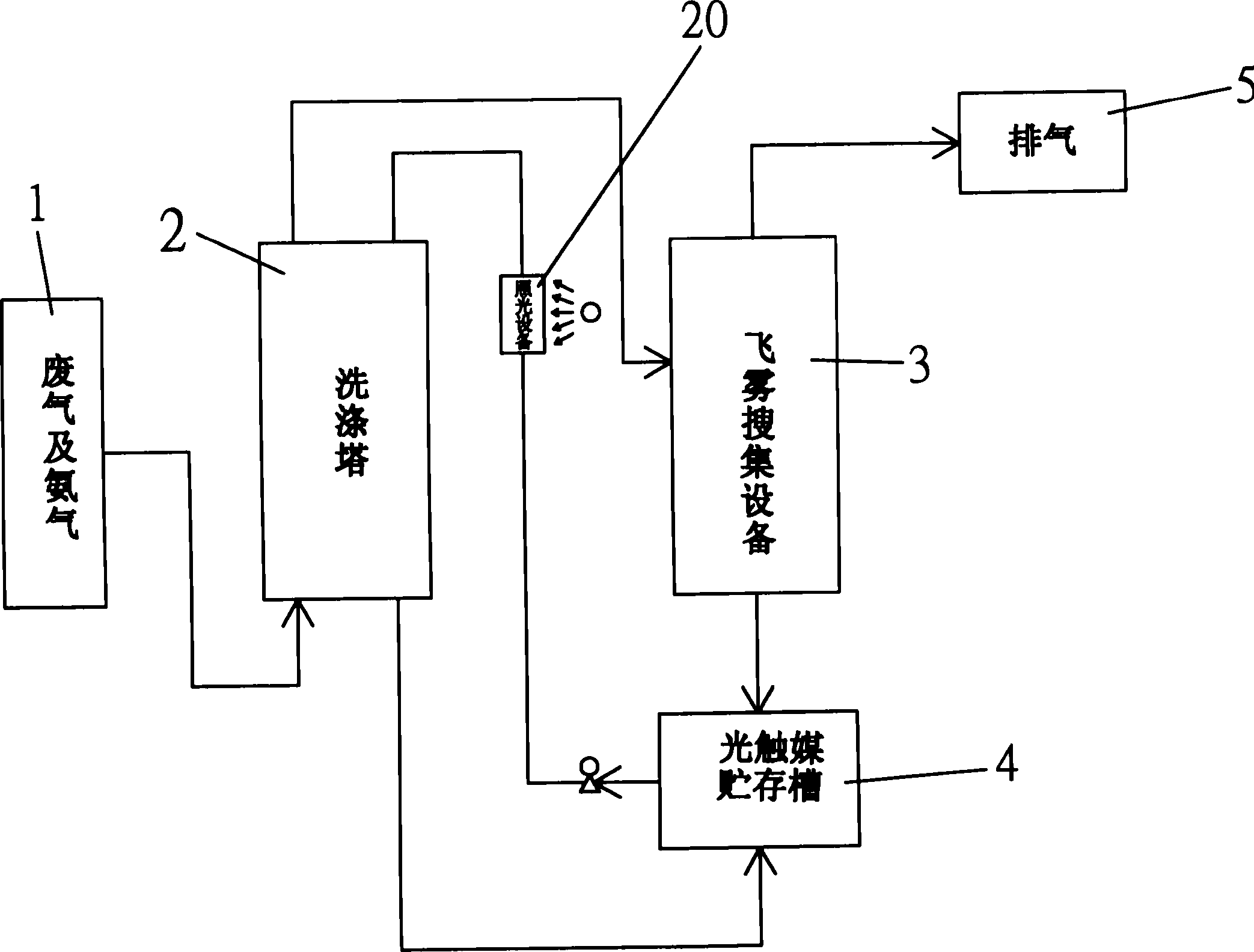

System for treating volatile organic compound, nitric oxide, and oxysulfide by using photocatalyst

A technology for organic compounds and nitrogen oxides, which is applied in chemical/physical/physical-chemical processes of energy application, chemical instruments and methods, separation of dispersed particles, etc. Exhaust gas and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

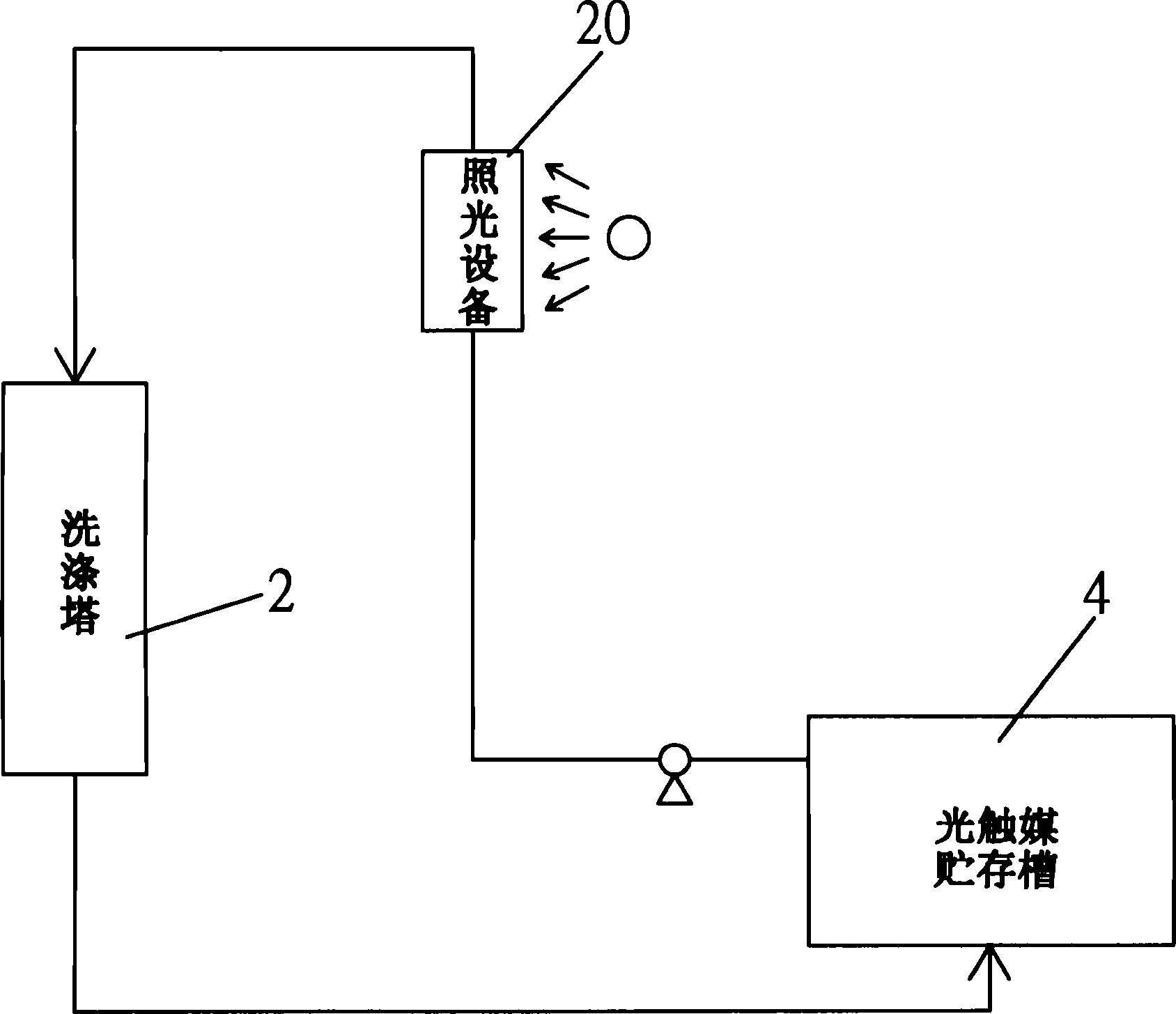

Embodiment 1

[0030] In 100×100×200(cm 3 ) in the return pipe (diameter 1 inch) of the washing tower 1 system, set up a 50-centimeter lighting area with a glass tube near the inlet section, and place a 1500LUX white fluorescent lamp at a distance of 30 centimeters. Set up the flying mist collection equipment, use the visible light titanium dioxide photocatalyst sol solution as the washing liquid, feed in the gas containing mercaptan (content 5ppm), the flow rate is 40CMM (that is, the flow rate of 40 cubic meters per minute), and the circulation speed of the washing liquid is adjusted to be With a flow rate of 20 liters per minute, it is found that the mercaptan content at the outlet of the treatment system can be reduced by less than 0.01ppm (it can no longer be measured), which meets the environmental protection emission standard (environmental protection emission standard: 0.1ppm).

Embodiment 2

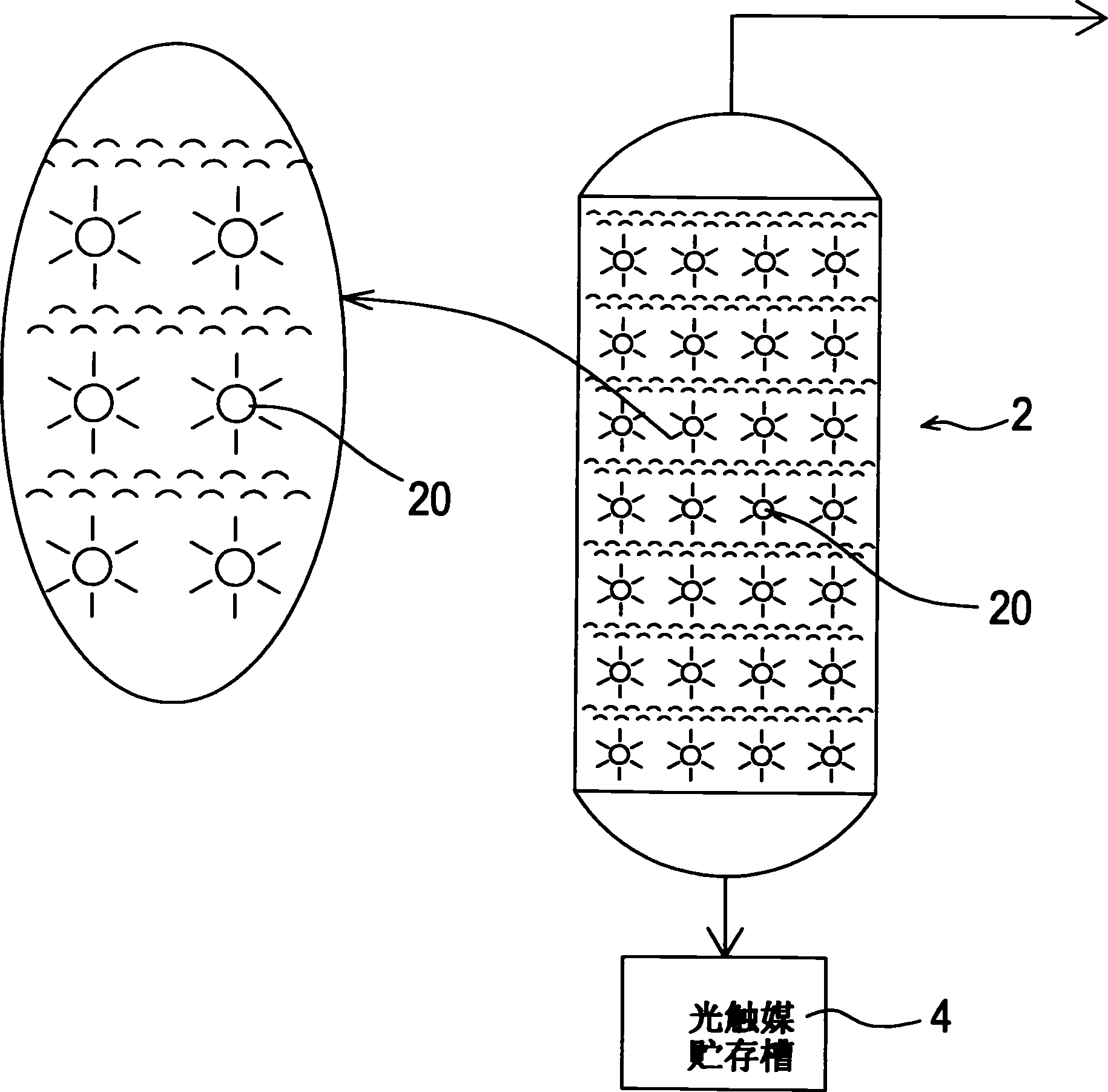

[0032] At 120×120×200(cm 3 ) in the washing tower 1 system, set up 1W blue LED lamps (4 for each height) at the heights of 50 cm, 100 cm, and 150 cm, and set up mist collection equipment at the exit to use visible light titanium dioxide photocatalyst sol solution As the washing liquid, the gas containing formaldehyde (content 5ppm) is introduced, the flow rate is 20CMM (that is, the flow rate of 20 cubic meters per minute), and the circulation speed of the washing liquid is adjusted to a flow rate of 20 liters per minute. It is found that the formaldehyde content at the outlet of the treatment system can be reduced. The reduction is less than 0.01ppm (so that it cannot be measured), which meets the environmental emission standard (environmental emission standard: 0.2ppm).

Embodiment 3

[0034] At 120×120×200(cm 3 ) in the washing tower 1 system, set up ultraviolet lamps (wavelength 365nm, 10W) at heights of 50 cm, 100 cm, and 150 cm (4 lamps for each height), add mist collection equipment at the exit, and use titanium dioxide photocatalyst The sol solution is the washing liquid, which is fed with the gas containing methylamine (content 1ppm), the flow rate is 40CMM (that is, the flow rate of 40 cubic meters per minute), and the circulation speed of the washing liquid is adjusted to be the flow rate of 20 liters per minute, and it is found that the outlet of the treatment system The content of methylamine can be reduced below 0.01ppm (cannot be measured), which meets the environmental emission standard (environmental emission standard: 0.02ppm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com