Screw electromagnetic coil disk and its producing method

A technology of electromagnetic coils and helical coils, applied in coil devices, cooling/ventilation/heating transformation, metal processing equipment, etc., can solve the problem of accelerating the aging cycle of electronic components in the furnace, improving the Q value of electromagnetic coil disks, and accelerating the insulation of enameled wires The problem of layer aging period and other issues is achieved, and the effect of ventilation and heat dissipation is remarkable, the manufacturing process is simple, and the inter-turn spacing is consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] see Figure 5 As shown, a spiral electromagnetic coil disk 4-2 of the present invention is planar, and its wire material is aluminum alloy, and the wire cross section is rectangular. The range is between 0.3-0.6 mm, which is selected according to the size of the coil disk. In this embodiment, the inter-turn spacing 4-4 is selected as 0.5 mm. For a single-layer coil disk, the thickness of the rectangular wire is generally 1.5-2.5mm, and the width is determined according to the power, outer diameter, number of turns and other parameters of the coil disk.

[0029] see Figure 6 As shown, the above-mentioned spiral electromagnetic coil disk 4-2 is installed and fixed on the plastic wire disk support 7, and its two ports are riveted with the aluminum terminal 4-6 plated with silver on the surface to become an electromagnetic heating coil disk for the induction cooker.

Embodiment 2

[0031] see Figure 1-Figure 6 Shown, the manufacturing method of a kind of spiral electromagnetic coil disk of the present invention is like this:

[0032] (1) Using a punching machine to punch out a circular green sheet 4 with a thickness of 1.5 mm according to a predetermined diameter.

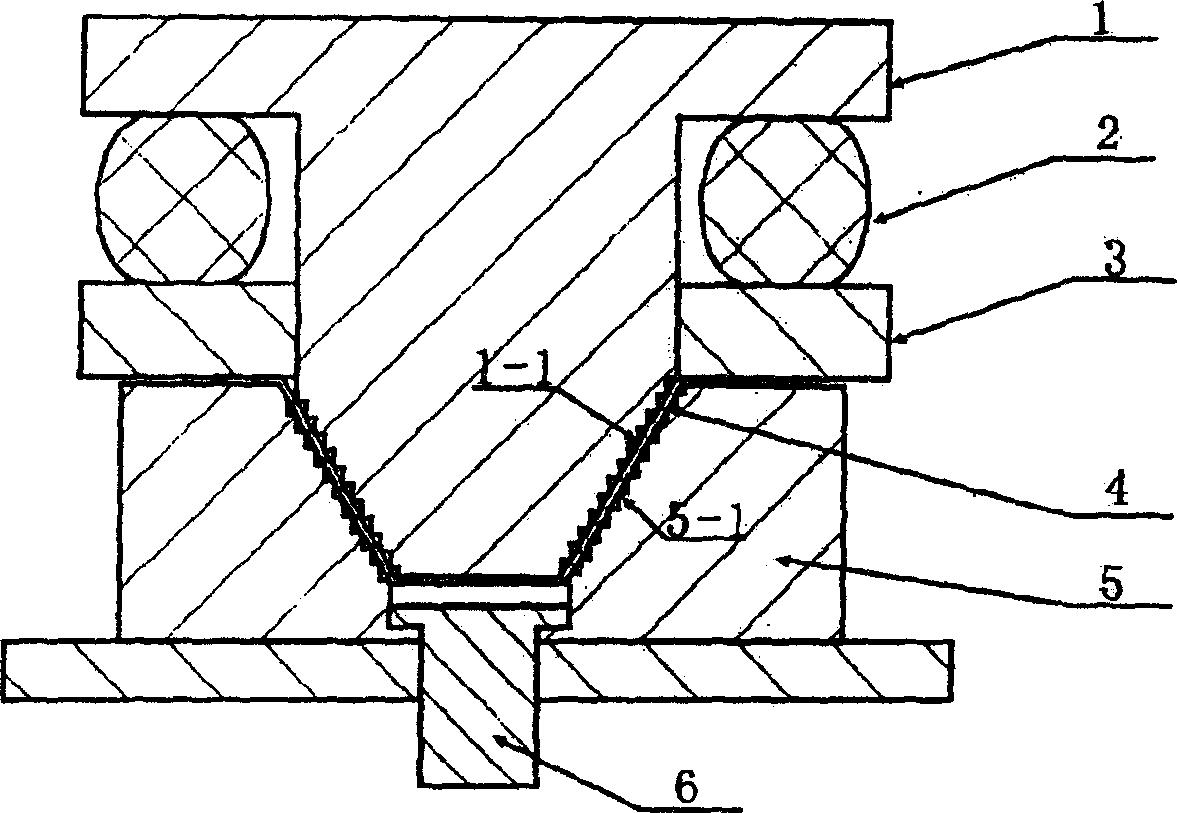

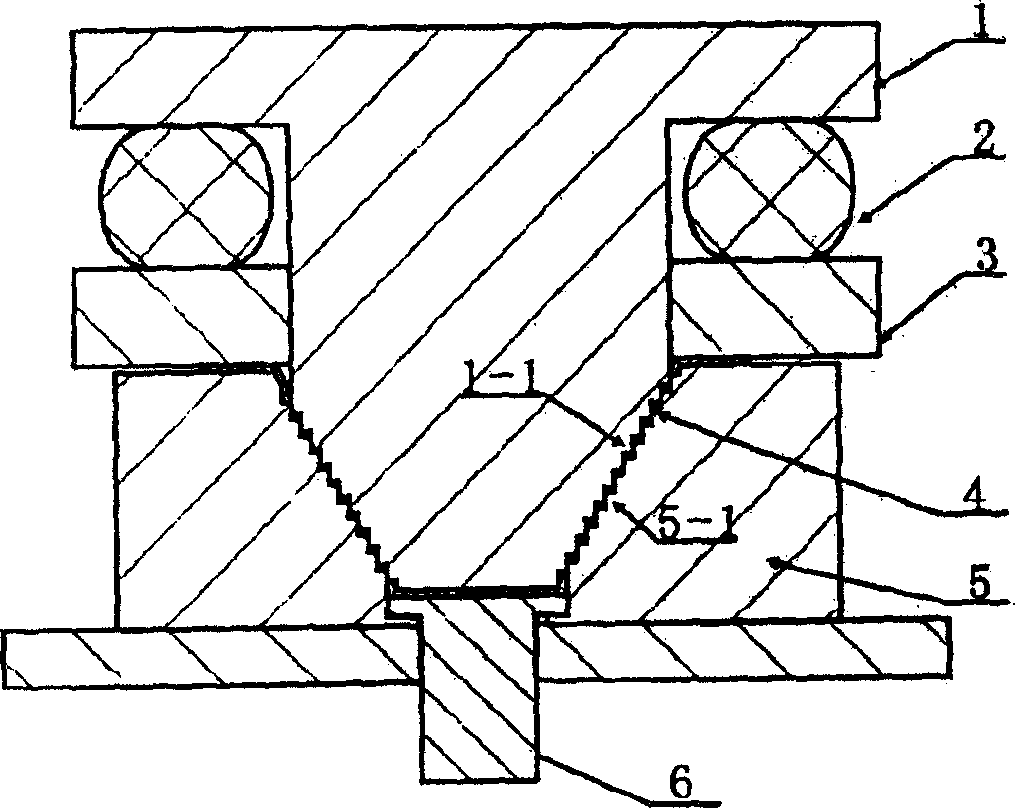

[0033] (2) The movable mold 1 and the lower mold 5 are installed on the press, and the corresponding contact surfaces of the movable mold 1 and the lower mold 5 are provided with matching spiral blades 1-1 and 5-1, and the circular aluminum The blank 4 is placed between the blank holder 3 and the lower die 5, and the center of the bottom of the lower die 5 is equipped with an ejector rod 6. When the press is working, the movable mold 1, the elastic glue 2, and the blank holder 3 move downward. The blankholder 4-1 produces blankholder force, and when the movable mold 1 continues to descend, the aluminum billet 4 is stretched into a flat-bottomed concave cone disc by the movable mold 1 and t...

Embodiment 3

[0039] In order to improve the conductivity of the coil disc, aluminum sheets with a thickness of 0.5-0.8mm can be used to make thin flat-shaped spiral coil discs according to the method in Example 2, and the insulating paint is evenly sprayed on the bonding surface of each thin coil disc by spraying. Then, according to the stacking thickness requirements, stack 2-4 thin flat-shaped spiral coil disks and dry them under pressure. Finally, the electromagnetic heating coil disk of the aluminum rectangular wire cross-section is made by the method of example 2 for the electromagnetic oven.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com