Viscose artificial silk continuous spinning technique and continuous spinning machine

A technology of viscose rayon and spinning process, which is applied in the textile field, can solve the problem that the four-roller and eight-filament continuous spinning scheme is not feasible, and achieve the effects of guaranteeing the quality of rayon, large benefits, and control of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

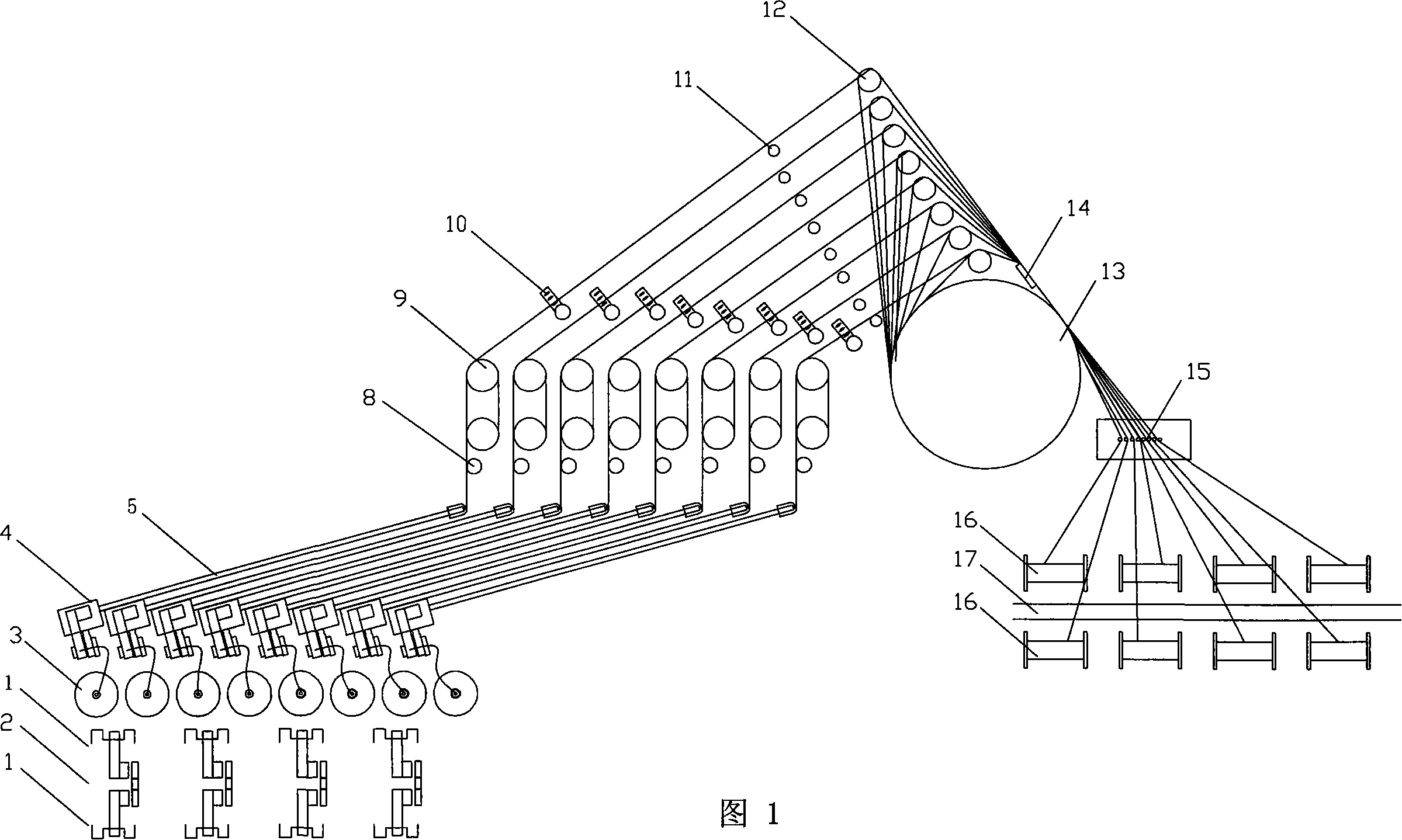

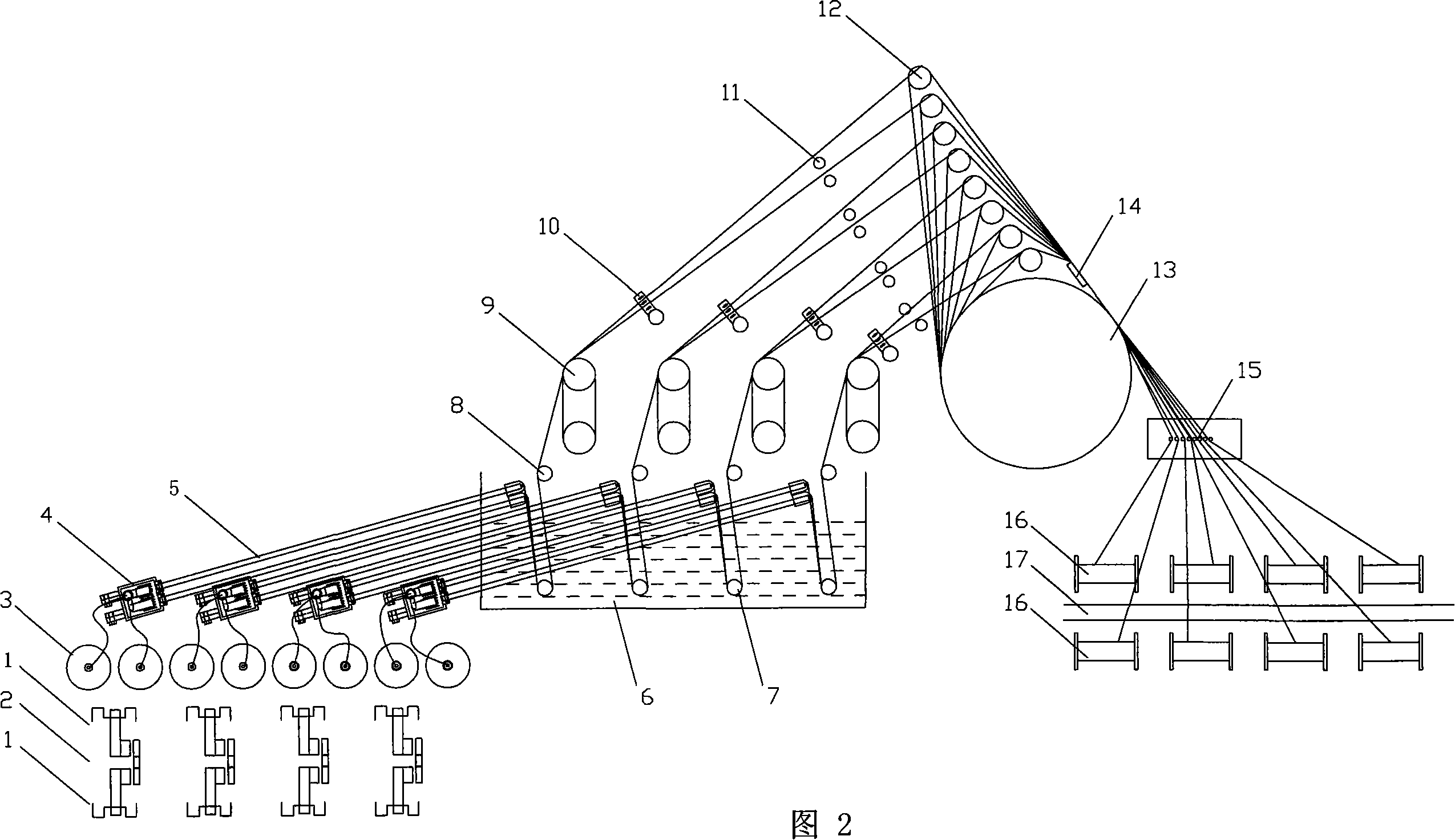

[0042] Embodiment one: viscose rayon continuous spinning process

Embodiment 1

[0044]The steps include: supplying glue from the rubber supply pipe, spinning the spinneret, and forming in the forming tube. After passing through the acid scraper, the filaments coming out of the forming tube are wound on the pair of rollers composed of a large processing roller and a small spinning roller. The filament enters and is wound from one end of the pair of rollers, spirally winds to the other end of the pair of rollers, and winds out from the other end of the pair of rollers, and is wound on the bobbin tube through a wire guide to form a wire bobbin. The pair of rollers includes 1 large processing roller and 6-10 (preferably 8) small spinning rollers, and the large processing rollers form 6-10 (preferably 8) pairs of rollers in one-to-one correspondence with each spinning small roller, 6 -10 (preferably 8) sets of 6-10 (preferably 8) filaments formed by glue supply, spinning, and forming devices correspond to 6-10 (preferably 8) small spinning rollers, and are resp...

Embodiment 2

[0046] In order to save space, two forming tubes and two spinnerets are installed in the reaction box, and 6-10 (preferably 8) sets of spinning and forming devices form 3-5 groups of spinning forming components; The tapered drafting rollers are drafted to the small spinning rollers, and the drafting rollers have 3-5 (preferably 4) pairs, and two or more filaments run on each pair of drafting rollers. Spinning forming components can also adopt other structural forms, such as installing three spinnerets and three forming tubes in one reaction box, the number of groups of spinning forming components in one unit of spinning machine and the number of spinnerets and forming tubes in each group. The number can be adjusted according to the number of spinning, and the number of draft coagulation rollers and small spinning rollers corresponds to the number of filaments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com