Mixed ammonia leaching method for multi-metal concretion and cobalt-rich skull in deep sea

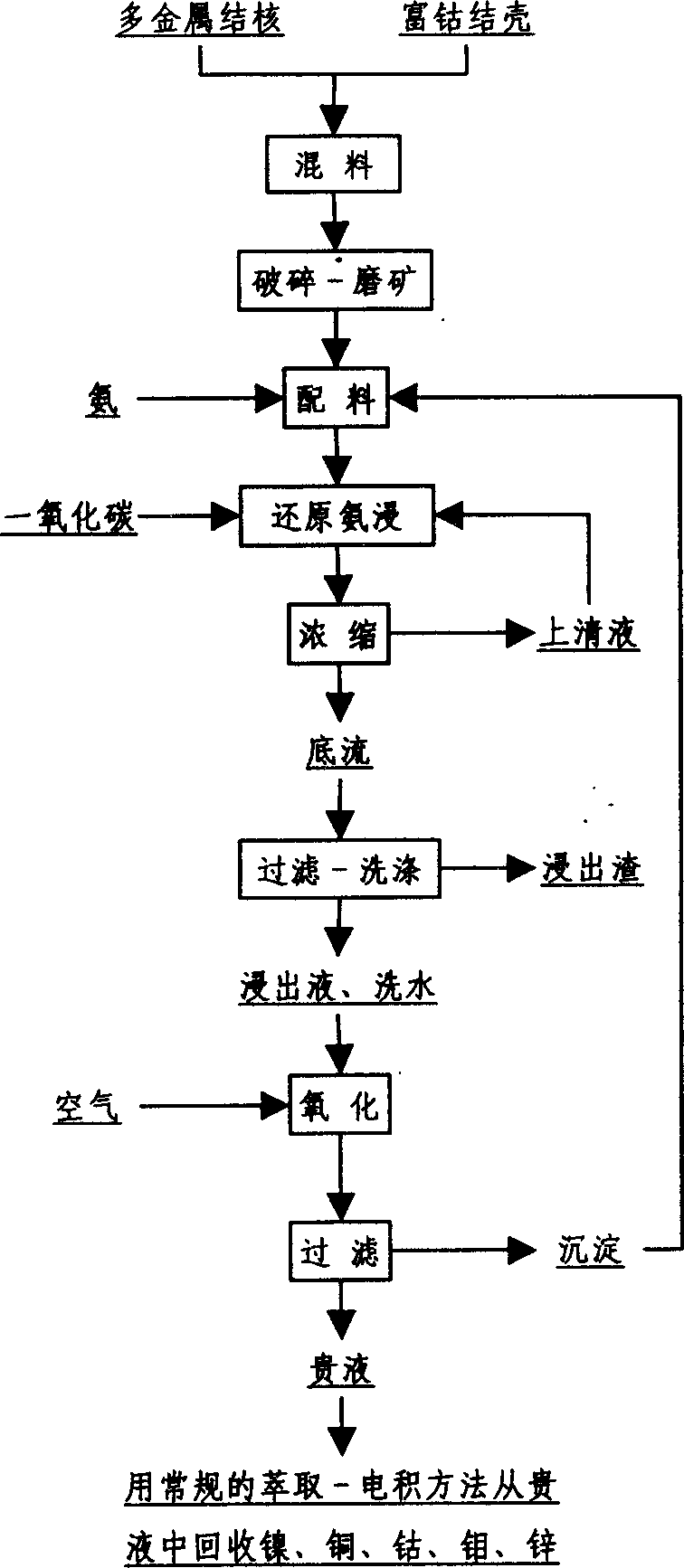

A technology for polymetallic nodules and cobalt-rich crusts is applied in the direction of improving process efficiency, which can solve the problems of high cost, low cobalt recovery rate, and impact on process economic benefits, and achieve the effect of reducing carbon monoxide consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take 3g of polymetallic nodules-1 and 3g of cobalt-rich crusts, grind them to -0.074mm and account for 70.76%, mix them and add them to 120g / l NH 3 , 40g / l SO 4 2- , 3g / l Co 2+ , 11.3g / l Ni 2+ , 8g / l Cu + In the ammonia-ammonium sulfate solution, the liquid-solid weight ratio is 40:1, the leaching temperature is 45°C, and the carbon monoxide flow rate is 0.4m 3 / t nodules·min, leaching for 2h. The leaching rate of cobalt is 90.75%.

Embodiment 2

[0046] Take 6g of polymetallic nodules-2 and 3g of cobalt-rich crusts, mix them, grind them to -0.074mm, account for 84.76%, add them to 60g / l NH 3 , 96g / l SO 4 2- , 2.5g / l Co 2+ , 8.6g / l Ni 2+ , 10g / l Cu + In the ammonia-ammonium sulfate solution, the liquid-solid weight ratio is 30:1, the leaching temperature is 40°C, and the carbon monoxide flow rate is 0.8m 3 / t·min, leaching for 3h. The leaching rate of cobalt is 88.5%.

Embodiment 3

[0048] Take 9g of polymetallic nodules-1 and 3g of cobalt-rich crusts, grind them to -0.074mm respectively, accounting for 70%, mix them and add them to 100g / lNH 3 , 40g / l SO 4 2- , 3g / l Co 2+ , 11.3g / l Ni 2+ , 15g / l Cu + In the ammonia-ammonium sulfate solution, the liquid-solid weight ratio is 20:1, the leaching temperature is 70°C, and the carbon monoxide flow rate is 1.2m 3 / t·min, leaching for 4h. The leaching rate of cobalt is 90.75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com