Method and device for in situ preparing zinc oxide nanometer crystal using coaxial oxygen transporting laser

A zinc oxide nano, in-situ preparation technology, applied in the field of ceramic materials, can solve the problems of difficult extraction and use of zinc oxide nano crystals, non-directional zinc oxide crystals, etc., and achieve the effect of convenient extraction and use, and easy extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

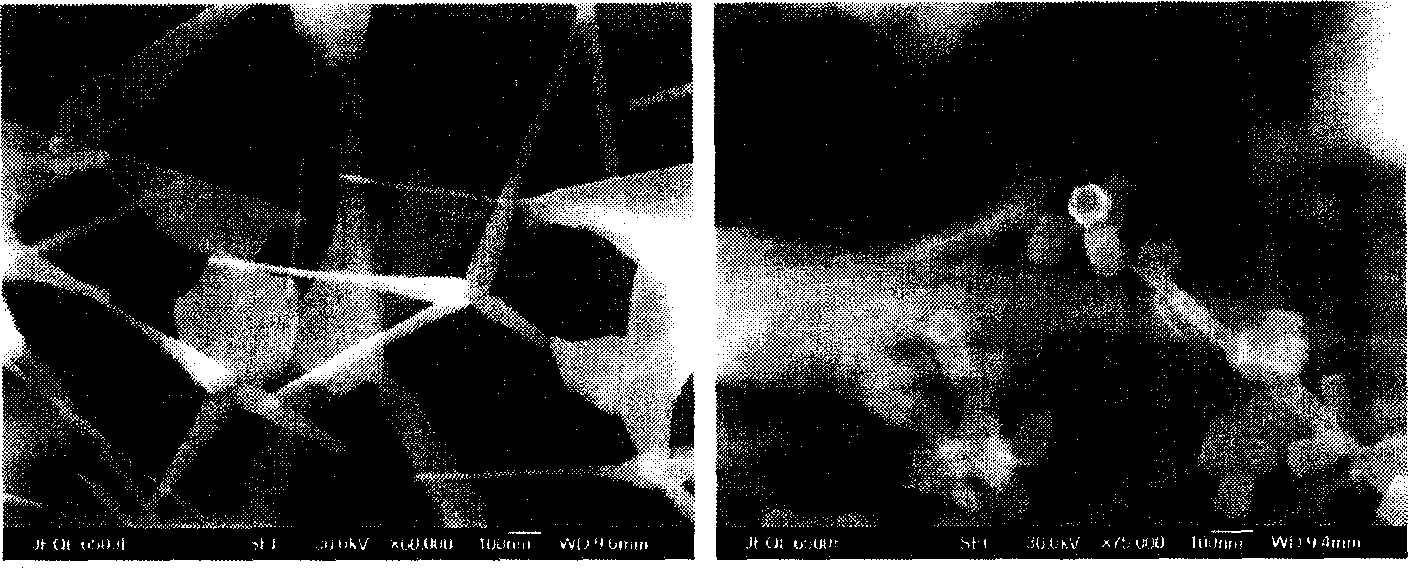

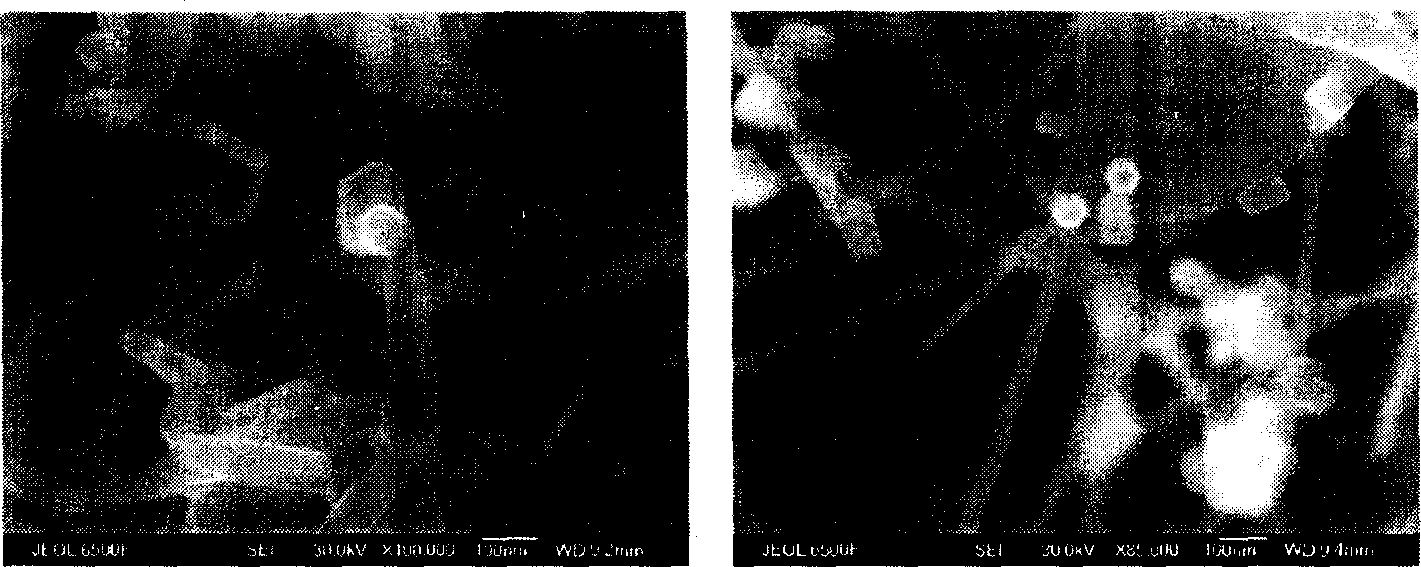

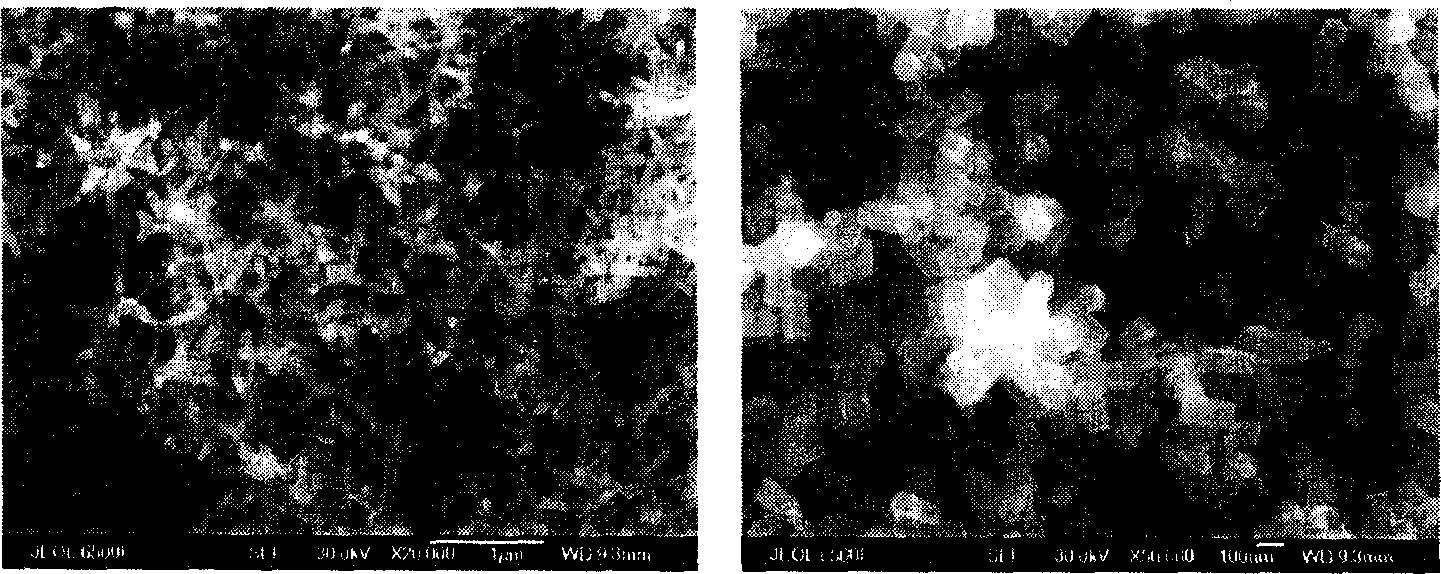

[0019] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The device for in-situ preparation of zinc oxide nanocrystals by coaxial oxygen-feeding laser of the present invention includes: reaction furnace 1, infrared thermometer 2, observation window 3, workbench 4, metal zinc plate 5, conical oxygen flow 6, laser beam 7. Coaxial oxygen delivery device 8, air supply hole 9, vacuum pump 10. Wherein the infrared thermometer 2 is set on the top of the reaction furnace 1, the observation window 3 is set on the side wall of the reaction furnace 1, the workbench 4 for placing the workpiece is set at the bottom of the reaction furnace 1, and in the corresponding reaction furnace 1 A coaxial oxygen supply device 8 composed of a coaxial conical oxygen flow 6 and a laser beam 7 is provided above, and an air supply hole 9 and a vacuum pump 10 are provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com