Method and plant for the heat treatment of solids containing iron oxide using a fluidized bed reactor

A fluidized bed reactor, iron oxide-containing technology, used in chemical instruments and methods, fluidized bed furnaces, chemical/physical processes, etc., can solve heat and mass transfer moderation, internal combustion is difficult to control, preheating solids Difficulty integrating suspension heat exchangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

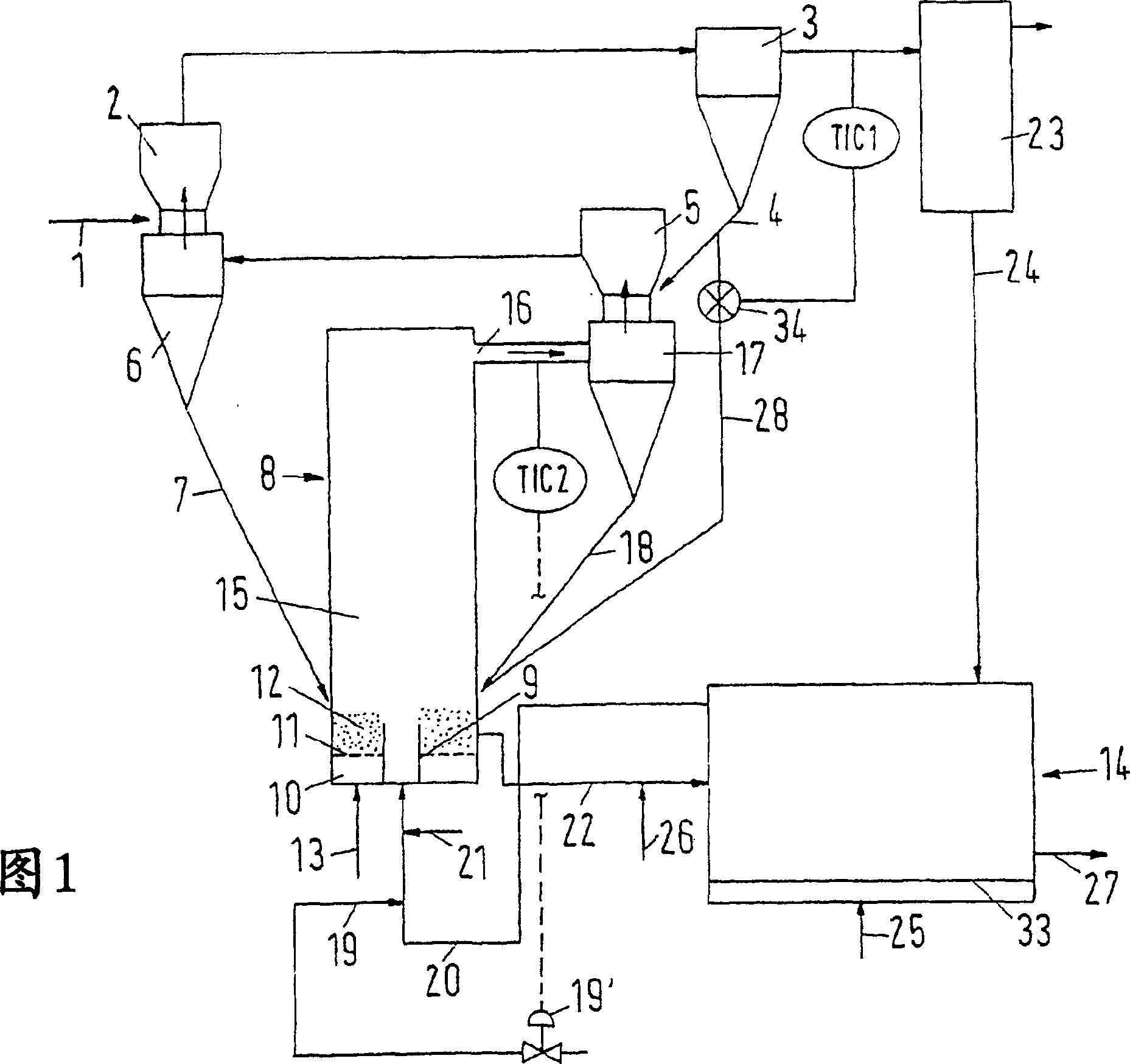

[0068] Embodiment 1 (heat treatment laterite type nickel ore)

[0069] In the device in Fig. 1, the laterite-type nickel ore with a particle size of less than 10mm is supplied to the suspension heat exchanger 2 with a screw conveyor of 220t / h. The laterite-type nickel ore contains:

[0070] 1.75wt% NiO

[0071] 31.4wt% Fe 2 o 3

[0072] 11wt% moisture

[0073] After passing through the first and second preheating sections, the pre-dried nickel ore is introduced into a calcining reactor 8 through a pipeline 7 . In addition, 6200Nm 3 / h natural gas as fuel (via pipeline 19), 71000Nm 3 / h air as combustion gas (through pipe 21) and 32600Nm 3 / h The waste gas from the reduction reactor (via pipeline 20) is supplied to the calcination reactor 8 through the center pipe 9, the gas temperature is about 800 ° C, and its composition is as follows:

[0074] 2vol%H 2

[0075] 18vol%H 2 o

[0076] 10vol% CO

[0077] 14vol% CO 2

[0078] 1vol%CH 4

[0079] 44vol%N 2

[00...

Embodiment 2

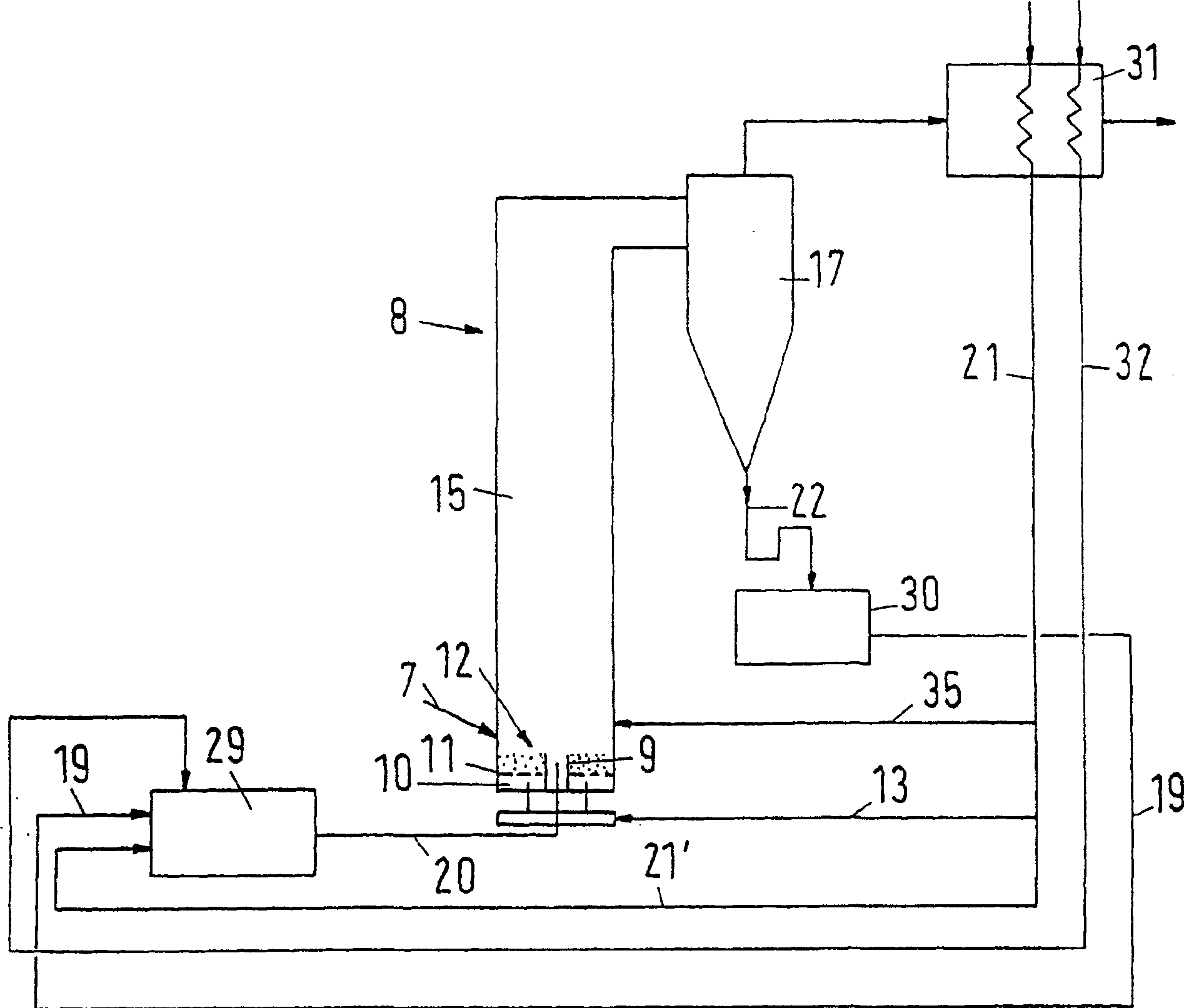

[0087] Embodiment 2 (heat treatment iron ore containing chromium)

[0088] exist figure 2 In the device, the 30t / h moisture content is 5wt%, Cr 2 o 3 Iron oxide-containing chromium ore with a content of 53 wt % and a particle size of not more than 6 mm is supplied to a reactor 8 through a pipe 7 .

[0089] 4500Nm 3 / h Fuel gas is supplied to combustion chamber 29 through pipeline 19, 5800Nm 3 / h The air preheated to 450°C is supplied to the combustion chamber 29 through the pipe 21', 4480Nm 3 / h The recirculation gas, also preheated to 450° C., is supplied to the combustion chamber 29 via the line 32 . On the opposite side of the combustion chamber, the temperature generated by combustion is about 13600Nm at 1600°C 3 / h The hot process gas is pumped through the pipe 20 and supplied to the reactor through the central pipe 9 . In addition, 7100Nm 3 / h Air is fed into the reactor via line 13 as fluidizing gas.

[0090] 21300Nm at 1100°C is extracted from the cyclone sepa...

Embodiment 3

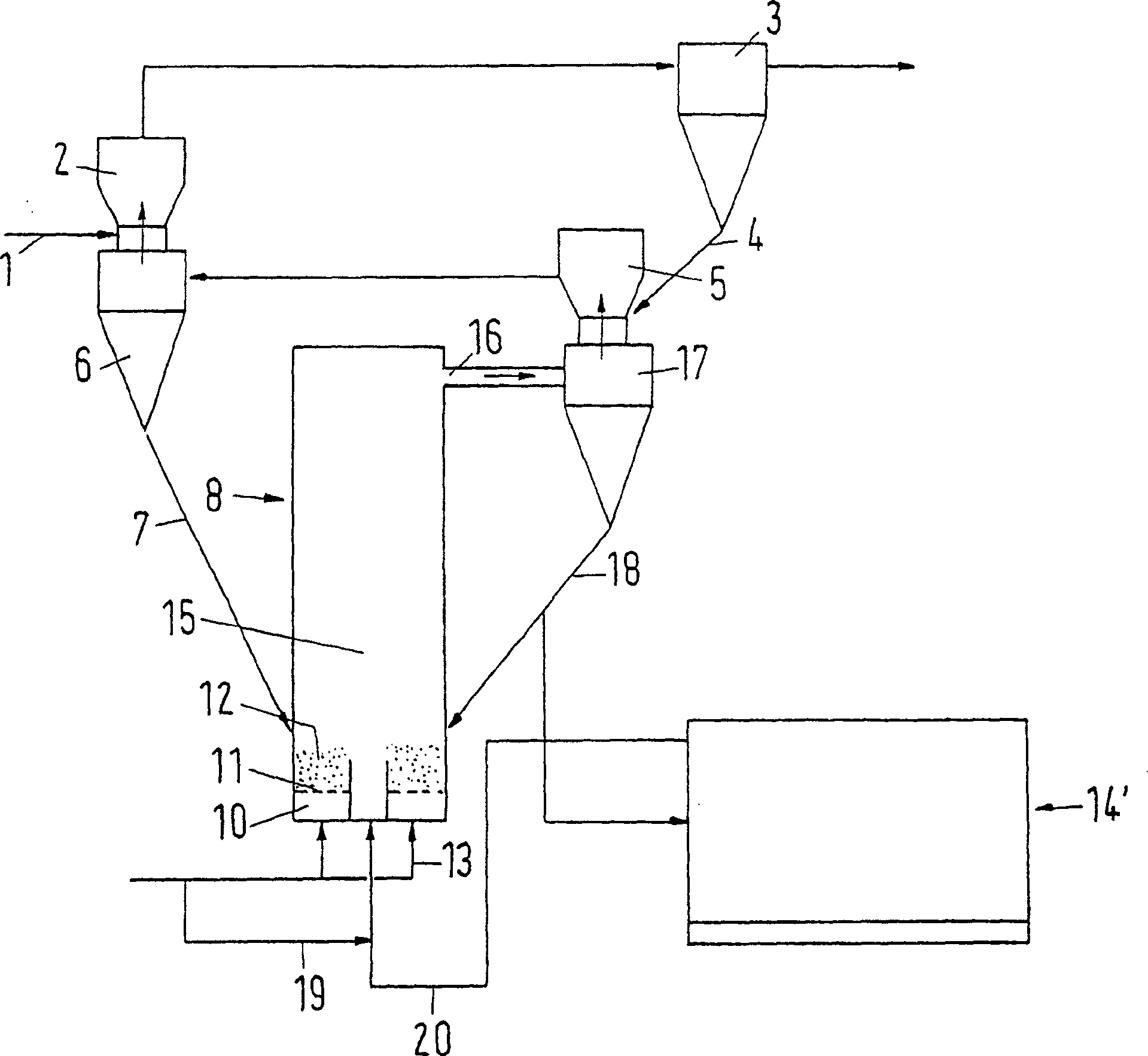

[0091] Embodiment 3 (heat treatment iron ore)

[0092] exist image 3 In the device, the 178t / h moisture content is 5wt%, Fe 2 o 3 Moist iron ore (hematite) with a content of 80 wt% and a particle size of less than 10mm is supplied to the suspension heat exchanger 2 through the screw conveyor 1, dried with exhaust gas from the cyclone separator 6, and preheated to about 277°C. The exhaust gas from cyclone separator 6 has the following composition:

[0093] 46.9vol% N 2

[0094] 7.6vol% H 2

[0095] 11.4vol%H 2 o

[0096] 5.7vol% CO

[0097] 28.4vol% CO 2

[0098] The solids are then separated from the gas phase in cyclone 3 and conveyed to suspension heat exchanger 5 where they are further heated to 561 ℃. The material then enters the annular fluidized bed 12 of the reactor 8 via the cyclone 6 and the conduit 7 .

[0099] 13000Nm 3 / h air (pipe 19) and 103000Nm 3 / h From the smelting reduction reactor 14' a mixture of hot off-gas (pipe 20) at about 1000°C is supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com