Method for preparing titanium aluminium alloy sheet material from foil element by hot pressing diffusion transformation synthesis

A technology of titanium-aluminum alloy and diffusion phase change, which is applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of low density and poor strength of titanium-aluminum alloy plates, and achieve material cost reduction, high density, and The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0007] Embodiment 1: This embodiment is completed by the following steps: 1. Selecting titanium foil 1 and aluminum foil 2, and chemically and mechanically treating the surfaces of titanium foil 1 and aluminum foil 2; 2. Stacking titanium foil 1 and aluminum foil 2 at intervals , and the outer layer is wrapped with tantalum foil 3; 3. The composite material formed in the second step is placed on a vacuum hot press at a temperature of 500 ° C ~ 600 ° C for 3 to 5 hours in the first stage; 860 ° C ~ 890 ° C in the second stage, 7 ~10 hours; the third stage is 1200 ℃ ~ 1400 ℃, the temperature and holding time of 1 ~ 2 hours are continuously heat treated, and the axial pressure of 8 ~ 30MPa is applied to the plate in the above three stages; 4. After the third step The composite material formed afterwards is cooled to obtain a titanium-aluminum alloy plate blank; 5. The tantalum foil 3 wrapped on the surface of the titanium-aluminum alloy plate blank obtained in step 4 is ground wit...

specific Embodiment approach 2

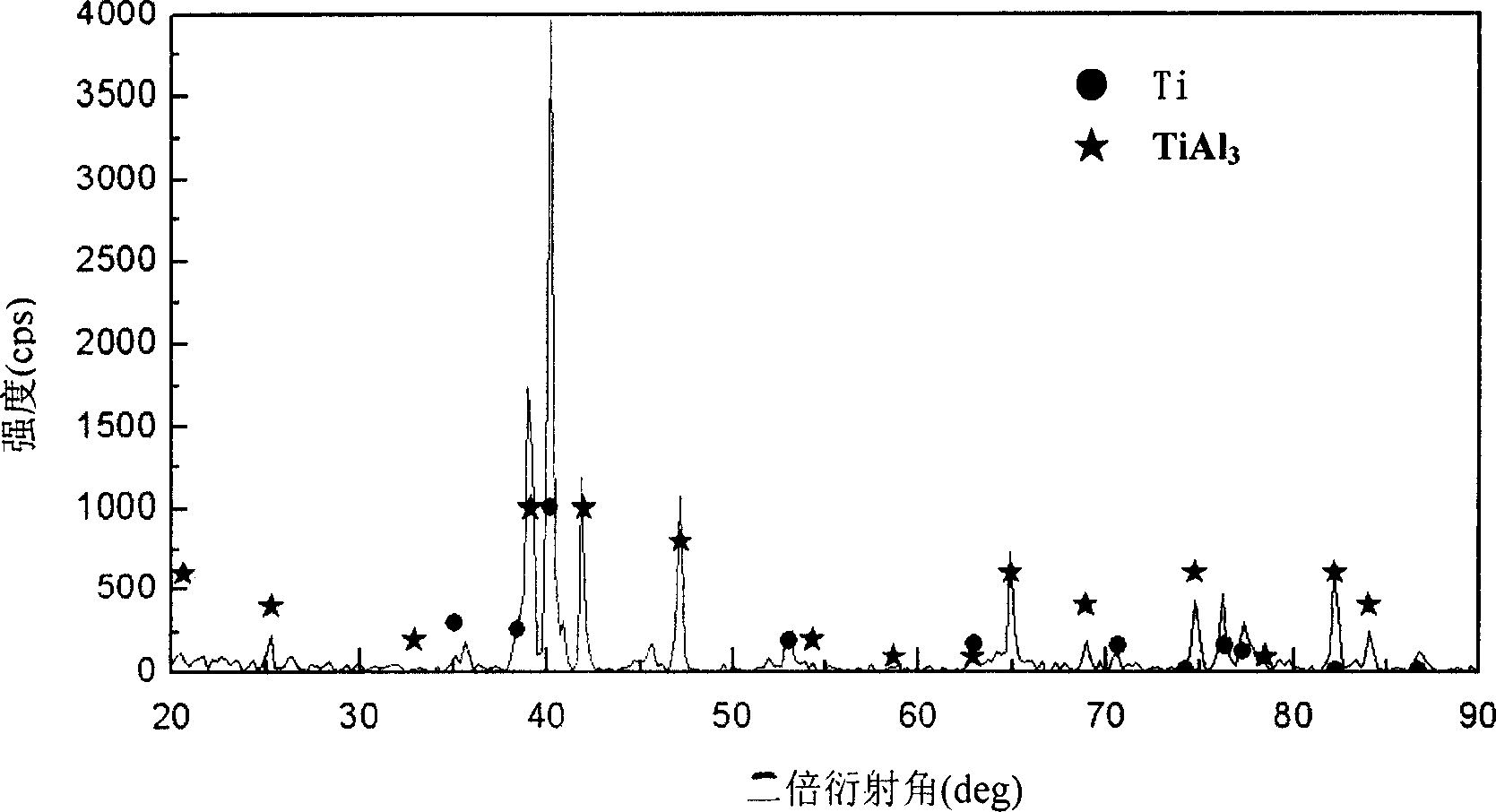

[0008] Embodiment 2: In this embodiment, titanium foil 1 and aluminum foil 2 with a thickness of 5-30 μm are used, and the surfaces of the selected titanium foil 1 and aluminum foil 2 are cleaned with a solvent. It is de-folded, the above-mentioned cleaned and de-folded titanium foil 1 and aluminum foil 2 are stacked at intervals (N layer of titanium foil, N-1 layer of aluminum foil), and the outer layer is wrapped with tantalum foil 3 to prevent titanium foil 1, The aluminum foil 2 is pasted with the hot press during the heat treatment process, and the titanium foil 1 and aluminum foil 2 wrapped with the tantalum foil 3 are placed on the vacuum hot press, and the first stage is 500 ℃ ~ 600 ℃, 3 ~ 5 hours, and applied The heat treatment process under the condition of axial pressure of 8-30MPa, this process is to make titanium and aluminum undergo solid-state diffusion reaction in solid state, completely consume the pure aluminum (A1) area, and generate in the edge area of tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com