Tip of soldering iron, process for producing the same, and electrical soldering iron and electrical solder sucking iron including the iron tip

一种制造方法、烙铁头的技术,应用在烙铁、制造工具、焊接位等方向,能够解决无法得到满意、自由度小等问题,达到提高耐侵蚀性或焊锡浸润性、焊锡浸润性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

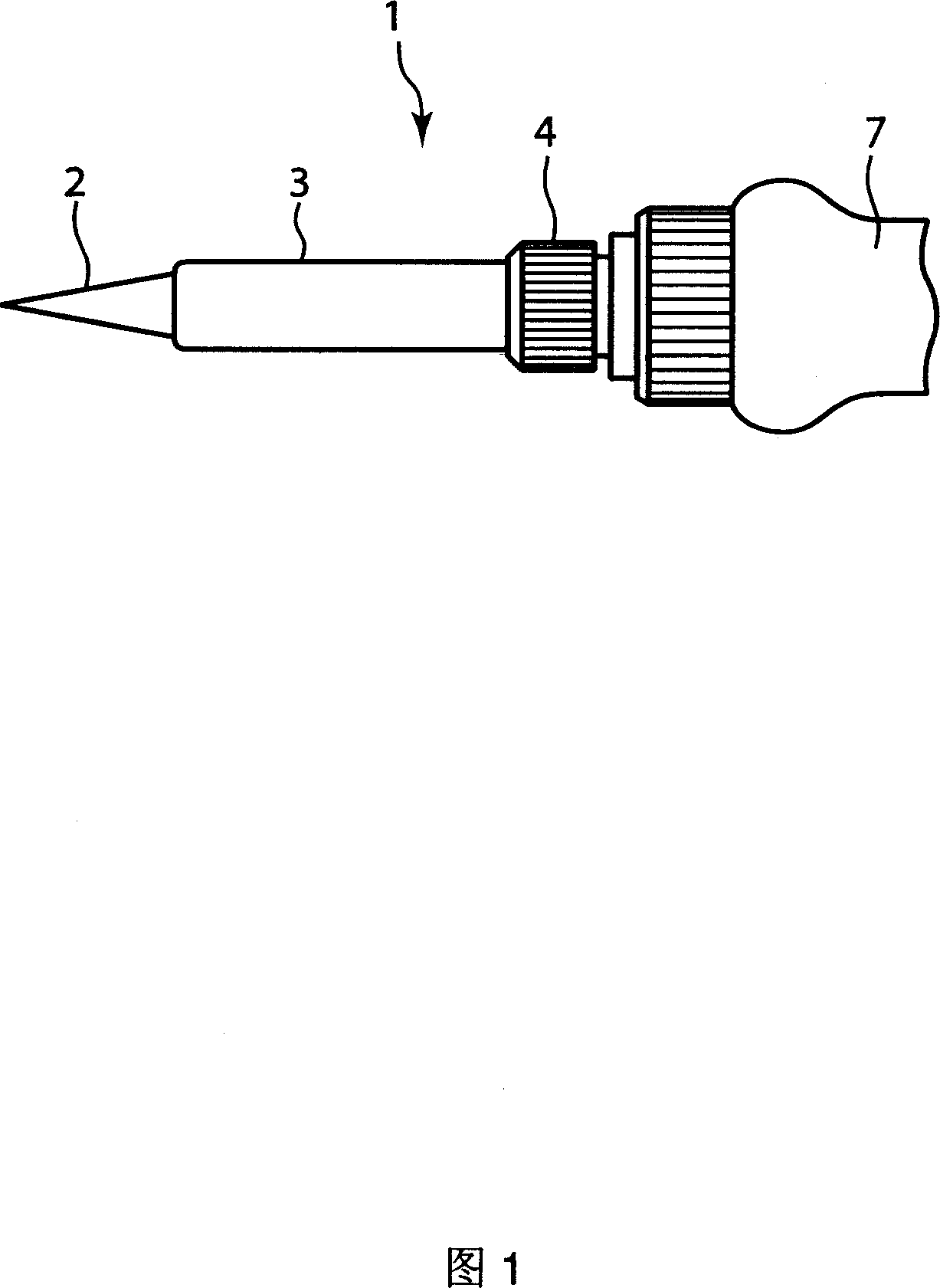

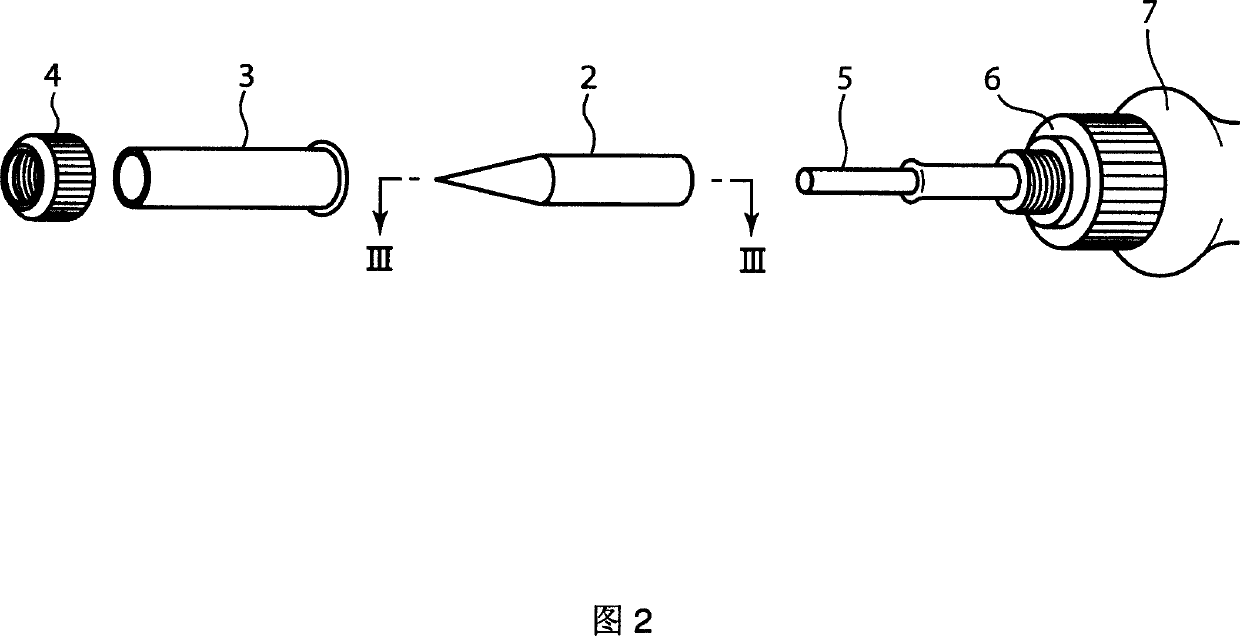

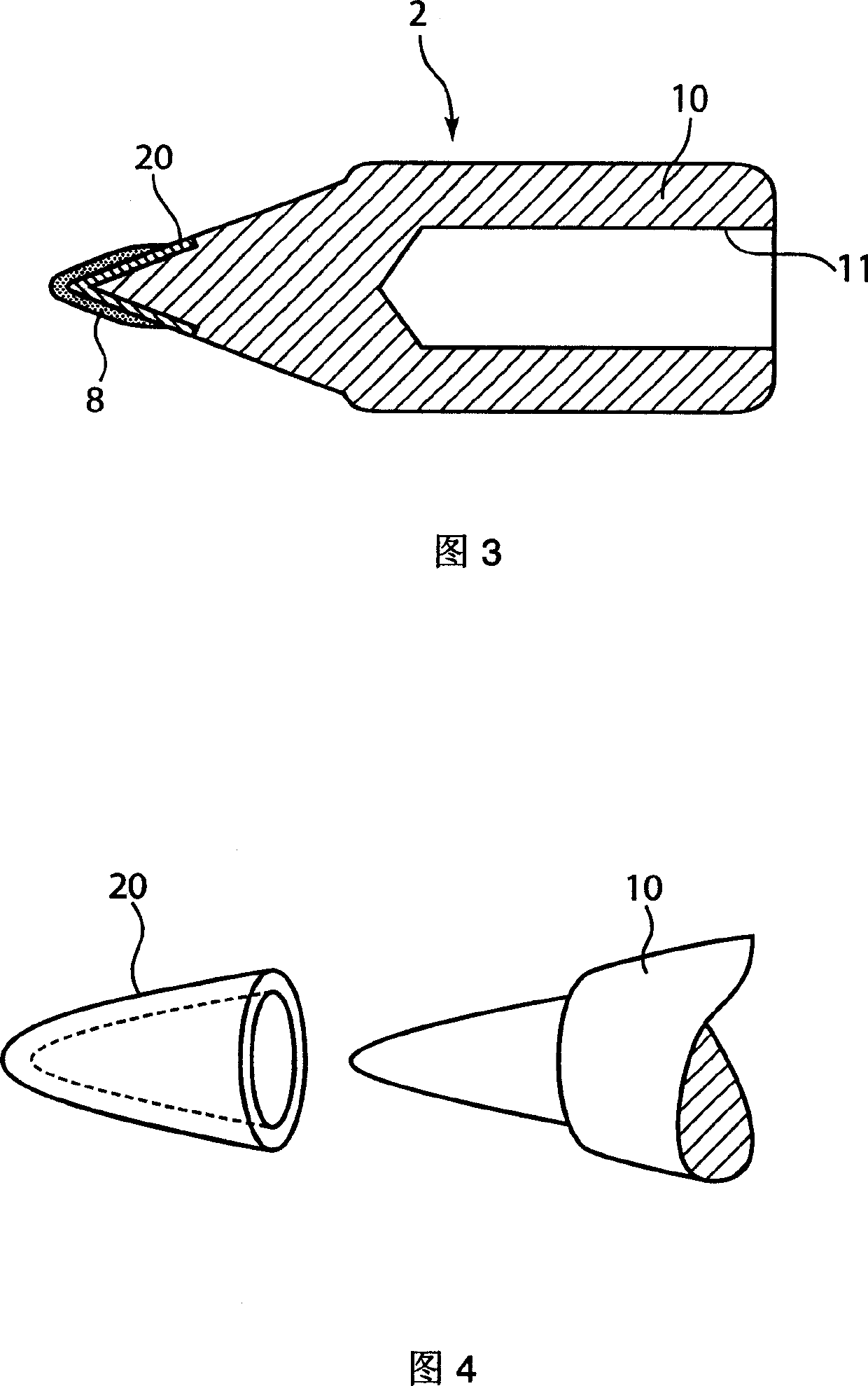

[0076] A first embodiment of the present invention will be described with reference to Figs. 1 to 16 . FIG. 1 is a front view of the vicinity of the tip of the soldering iron 1, and FIG. 2 is an exploded perspective view thereof. The tip part of the electric soldering iron 1 is provided with a soldering iron tip member 2 (corresponding to a soldering iron tip for soldering) which is housed in the protective tube 3 and whose conical tip protrudes from the protective tube 3 . The protective tube 3 is fixed on the threaded joint 6 of the electric soldering iron 1 by the cap nut 4 . In the soldering iron tip unit 2 , a concave portion 11 is provided inside the cylindrical main body covered by the protective tube 3 (see FIG. 3 ). The ceramic heater 5 protruding from the main body 7 of the electric soldering iron 1 is assembled in the concave portion 11 so as to be fitted therein. The ceramic heater 5 is a heating element that generates heat by turning on a power switch not shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com