Barium titanate low-dimensional nano powder material and its preparation method

A low-dimensional nanometer and nanopowder technology, applied in chemical instruments and methods, titanium compounds, calcium/strontium/barium compounds, etc., can solve the problem of large specific surface area and specific surface energy, high oxidation rate of fine-grained minerals, fine Mineral flotation problems and other problems, to achieve the effect of simple equipment, easy large-scale industrial production, and large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

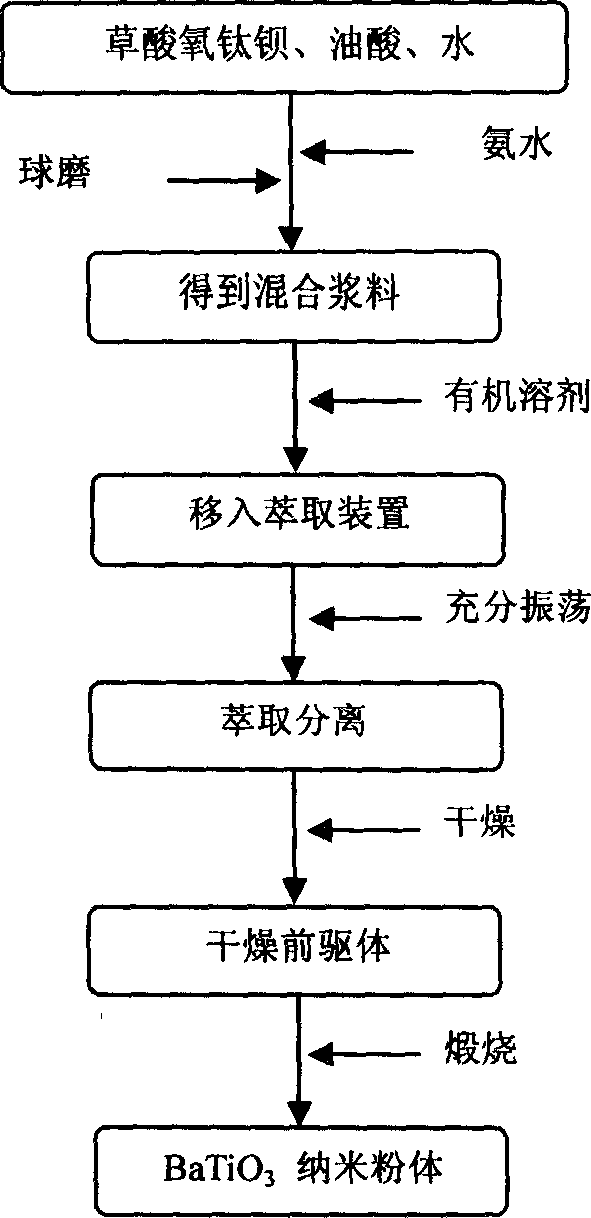

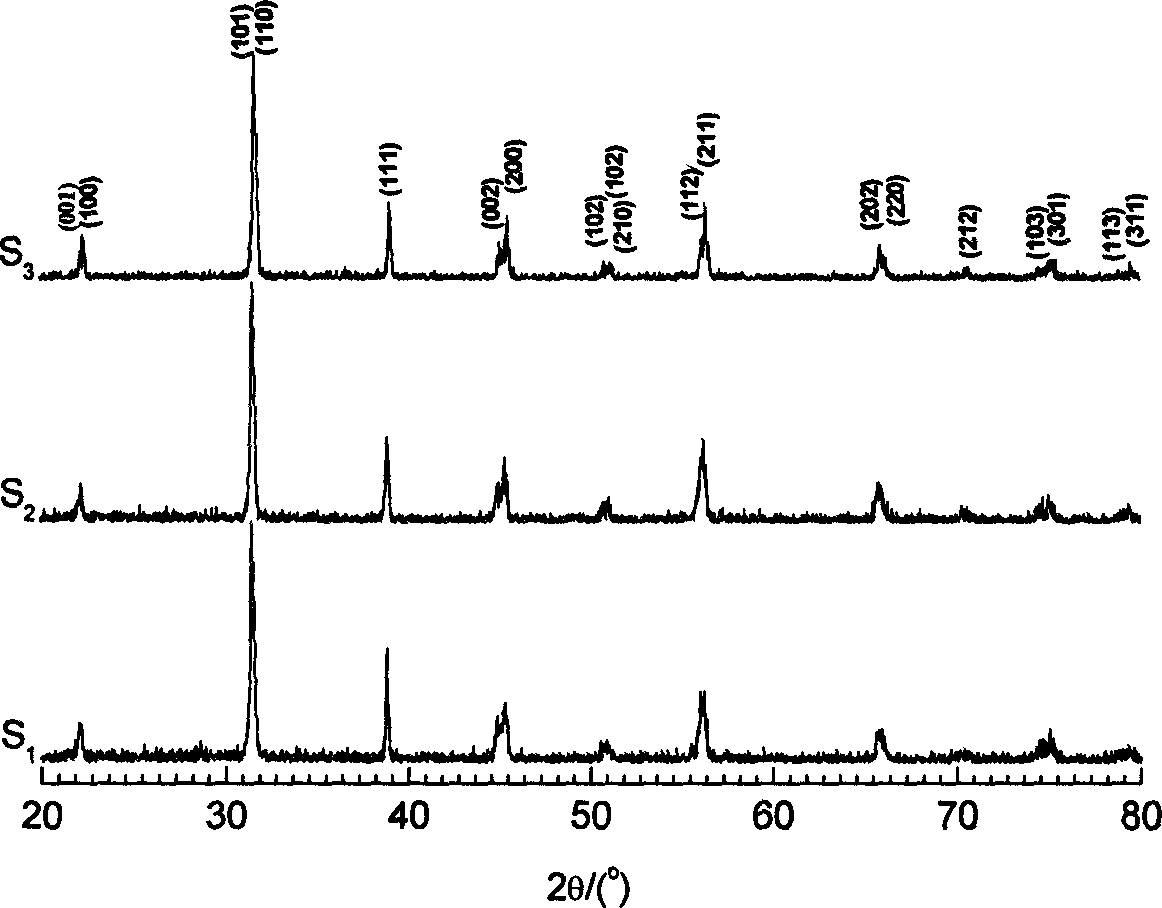

[0036] Weigh 50 grams of barium titanyl oxalate powder, put it into a polyurethane tank, use agate balls as the ball milling medium, add 50 ml of deionized water, drop in 1 ml of oleic acid, stir slightly, add ammonia water to the slurry until the pH value is 9. Put the lid on the planetary mill at 250 rpm, and continuously ball mill for 12 hours to obtain a white slurry; pour it into a pear-shaped funnel, add 50 grams of deionized water, mix well, add 15ml of petroleum ether dropwise, and shake vigorously After 10 minutes, it was placed on the iron stand for more than 6 hours. It was observed that the two phases of oil and water were separated, and the barium titanyl oxalate powder was extracted into the floating oil phase. In the tray, dry in an oven at 80°C; after drying, the powder is sieved, moved into a muffle furnace for calcination at 800°C, and kept for half an hour to obtain monodisperse spherical barium titanate powder, the grain size and shape are as follows: imag...

Embodiment 2

[0038]Weigh 50 grams of barium titanyl oxalate powder, put it into a polyurethane tank, use agate balls as the ball milling medium, add 50ml of deionized water, drop in 1.5ml of oleic acid, stir slightly, add ammonia water to the slurry until the pH value 10, cover the tank on a planetary mill at 250 rpm, and continuously ball mill for 12 hours to obtain a white slurry; pour it into a pear-shaped funnel, add 50 grams of deionized water, mix well, add 15ml of petroleum ether and 20ml of Terpineol, vibrate vigorously for 15 minutes, and then put it on the iron stand for more than 12 hours. It is observed that the oil and water phases are separated, and the barium titanyl oxalate powder is extracted into the floating oil phase. The titanium barium oil aggregates are moved into a tray and dried in an oven at 100°C; after drying, the powder is sieved, moved into a muffle furnace for calcination at 800°C, and kept for half an hour to obtain one-dimensional barium titanate nanorod pow...

Embodiment 3

[0040] Weigh 50 grams of barium titanyl oxalate powder, put it into a polyurethane tank, use agate balls as the ball milling medium, add 50ml of deionized water, drop in 2ml of oleic acid, stir slightly, add ammonia water to the slurry until the pH value is 11. Put the lid on a planetary mill at 250 rpm and continuously ball mill for 10 hours to obtain a white slurry; pour it into a pear-shaped funnel, add 50 grams of deionized water, mix well, add 15ml of petroleum ether and 15ml of pine Oleyl alcohol, shake vigorously for 22 minutes, and put it on the iron stand for more than 24 hours. It is observed that the oil and water phases are separated, the barium titanyl oxalate powder is extracted into the sinking oil phase, and the lower barium titanyl oxalate oil aggregate is directly moved In the tray, dry at 90°C in an oven; after drying, sieve the powder, move it into a muffle furnace for calcination at 900°C, and keep it warm for 1 hour to obtain rod-shaped barium titanate pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com