Beta-cyclodextrin/phenylpropanol inclusion and its preparing method

A technology of cyclodextrin and phenylpropanol, which is applied in the direction of active ingredients of hydroxyl compounds, non-active ingredients of polymer compounds, and drug combinations, etc., which can solve the problems of inconvenient use, easy discoloration, and frequent daily use of patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

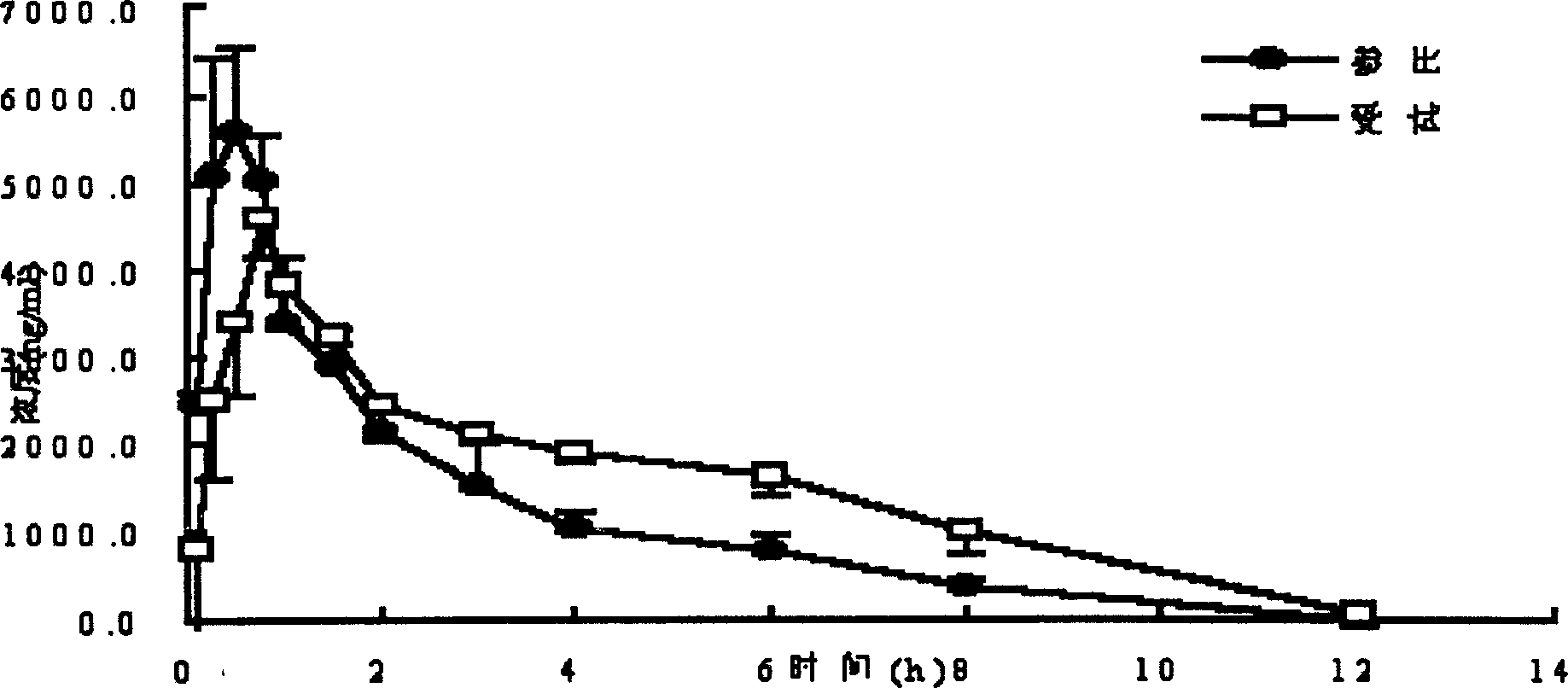

Image

Examples

Embodiment 1

[0034] Example 1, mix 1000 ml of pure water with 200 g of β-cyclodextrin, heat, add 20 g of phenylpropanol at 70°C, mix and stir for 5 hours, then cool at 5°C for 24 hours; filter, The solid was washed twice with water. Dry at 80°C for 24 hours to obtain a white solid clathrate.

[0035] Add the following auxiliary material components (mg) to the clathrate prepared above:

[0036] β-Cyclodextrin 1000

[0037] Microcrystalline Cellulose 120

[0038] Cornstarch 280

[0039] Citric acid 100

[0041] Sodium starch glycolate q.s

[0042] Stearic acid q.s

[0043] Pass the clathrate through a 100-mesh sieve, and fully mix it with other excipients shown in the above table at a ratio of 1:0.5 (W / W) to prepare a solid preparation raw material. Adopt wet granulation under the condition of 15-30°C, dry at 60°C for 20 hours, press the whole grain into tablets or fill capsules to obtain the product.

Embodiment 2

[0044] Example 2: basically the same as Example 1, but 2000 milliliters of pure water was mixed with 200 grams of β-cyclodextrin, heated, and 40 grams of phenylpropanol was added at a temperature of 35 ° C, and fully mixed and stirred for 15 hours; the added The proportion of auxiliary materials is 1:1 (W / W), and the ingredients of auxiliary materials are:

[0045] β-Cyclodextrin 500

[0046] Pregelatinized starch 160

[0047] Lactose 80

[0048] Mannitol 140

[0049] Crospovidone q.s

[0051] PEG4000 q.s.

Embodiment 3

[0052] Example 3: basically the same as Example 1, but 400 milliliters of pure water was mixed with 200 grams of β-cyclodextrin, heated, and 30 grams of phenylpropanol was added at a temperature of 80 ° C, and fully mixed and stirred for 0.5 hours; the added The proportion of auxiliary materials is 1:0.8 (W / W), and the ingredients of auxiliary materials are:

[0053] β-Cyclodextrin 1000

[0054] Microcrystalline Cellulose 120

[0055] Cornstarch 280

[0056] Low-substituted hydroxypropyl cellulose 100

[0057] Micronized silica gel q.s

[0058] Carboxymethyl starch sodium q.s

[0059] PEG6000 q.s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com