Method for preparing super-amphiphobic micro-nano film on metal surface

A metal surface, ultra-amphiphobic technology, applied to special surfaces, pre-treated surfaces, devices for coating liquids on surfaces, etc., to achieve the effects of strong practicability, strong operability, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

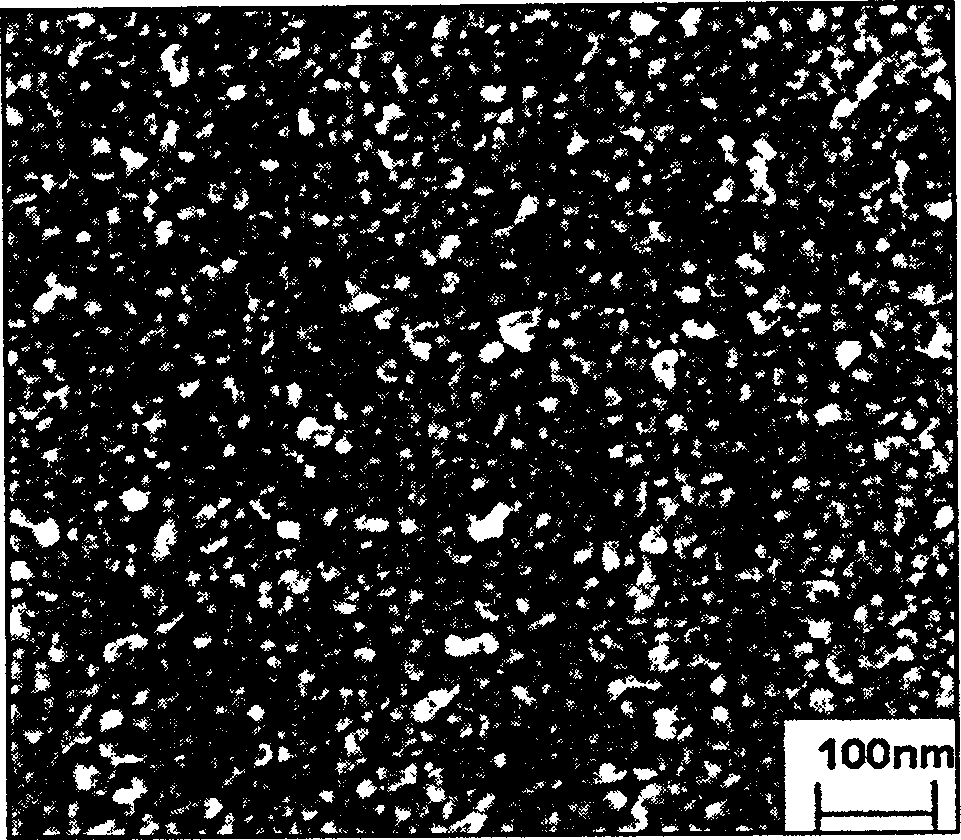

[0021] At room temperature and pressure, first add 1ml EAcAc to 20ml absolute ethanol, then add 4ml butyl titanate under stirring, after reacting for 1 hour, add 0.2ml water within 30 minutes, stir for 5 hours, and wait for coating. Submerge the pretreated metal substrate (surface mechanical polishing, cleaning treatment) in the sol for 5 minutes, and pull it at a constant speed of 0.5mm / s to form a hanging film on the metal surface. After natural drying, you can see a layer of colored nano-TiO2 film on the metal surface. After drying under infrared light for 30 minutes, repeat the above process 3 times, put it in a muffle furnace at a constant temperature of 450 ° C for 30 minutes, and naturally cool to prepare nano-TiO2. membrane. The surface morphology of the nanofilm was observed under a high-power scanning electron microscope (SEM). figure 1 shown, from figure 1 It can be seen that the membrane is a porous membrane, the surface is basically flat and orderly, the diamete...

Embodiment 2

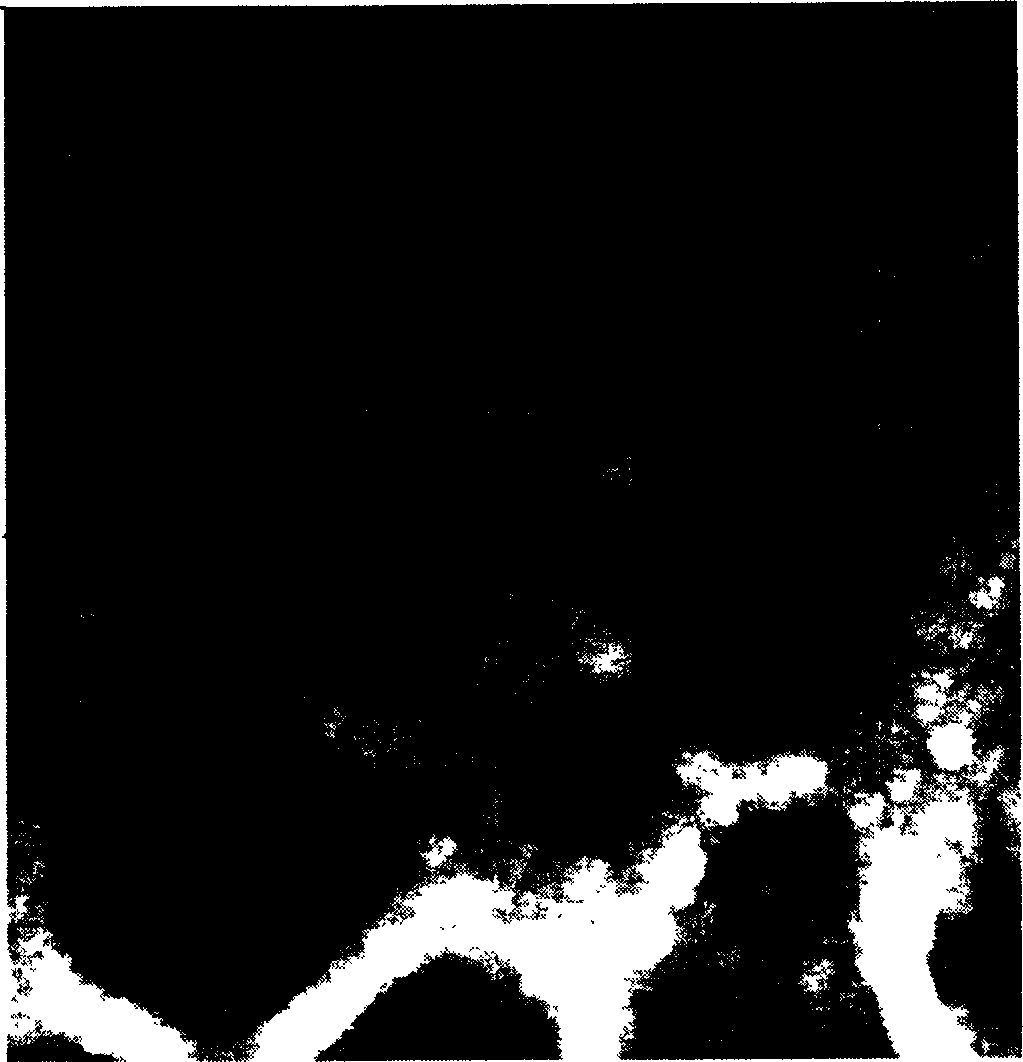

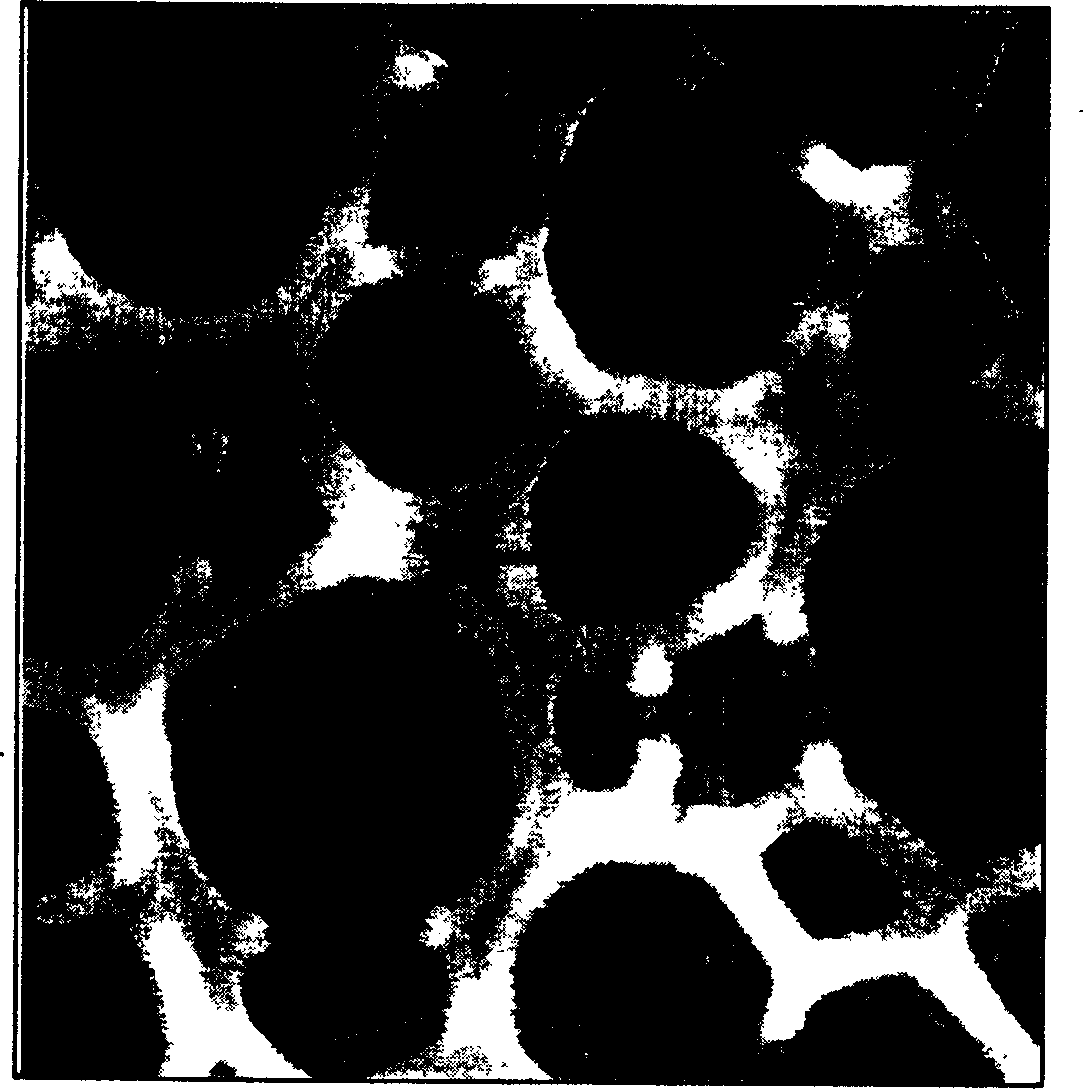

[0026] Using this technology to micronize the surface of the nano-TiO2 film, the morphology of the nano-film can be controlled by changing the temperature and time. Similarly, the nano-TiO2 film was suspended in three times of water (pH=7), treated with hydrothermal treatment at a constant temperature of 100° C. for 3 hours, and then dried at 200° C. after being taken out. Figure 4 In order to hydrothermally treat the surface morphology of the nano-TiO2 film at 100°C for 3h, it can be seen that the surface morphology is a uniformly distributed flower-like structure. The crystal form of the particles in the nanofilm before and after micro-nano surface treatment was characterized by XRD ( Figure 5 ),From Figure 5 It can be seen that the thin film of surface micro-nano structure is mainly TiO Characteristic crystal planes such as (101), (004), (200), (211), (204), (220) and (215) of anatase, illustrating that this method prepares The nanofilm does not affect the TiO2 crystal...

Embodiment 3

[0028] FSA was assembled on the surface of the micro-nano film after hydrothermal treatment in Examples 1 and 2 for 3 hours, put into 1% FSA alcohol solution and soaked for 1 hour to take it out, and dried at 170° C. for 1 hour to prepare hydrophobic micro-nano structure TiO2 film / 316L, test its surface wettability, the results are as Figure 6 shown. It can be known that the contact angles of the surface to water and cyclohexane are both 156±1°, which proves that the film with the micro-nano structure on the surface has obvious super-hydrophobic properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com