Process for preparing nano modified UV-cured resin coating

A curing resin and nano-modification technology, applied in the direction of coating, etc., can solve the problems of difficult control of process conditions, fast curing speed, incomplete curing, etc., and achieve the effect of prolonged curing time, complete curing and more uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

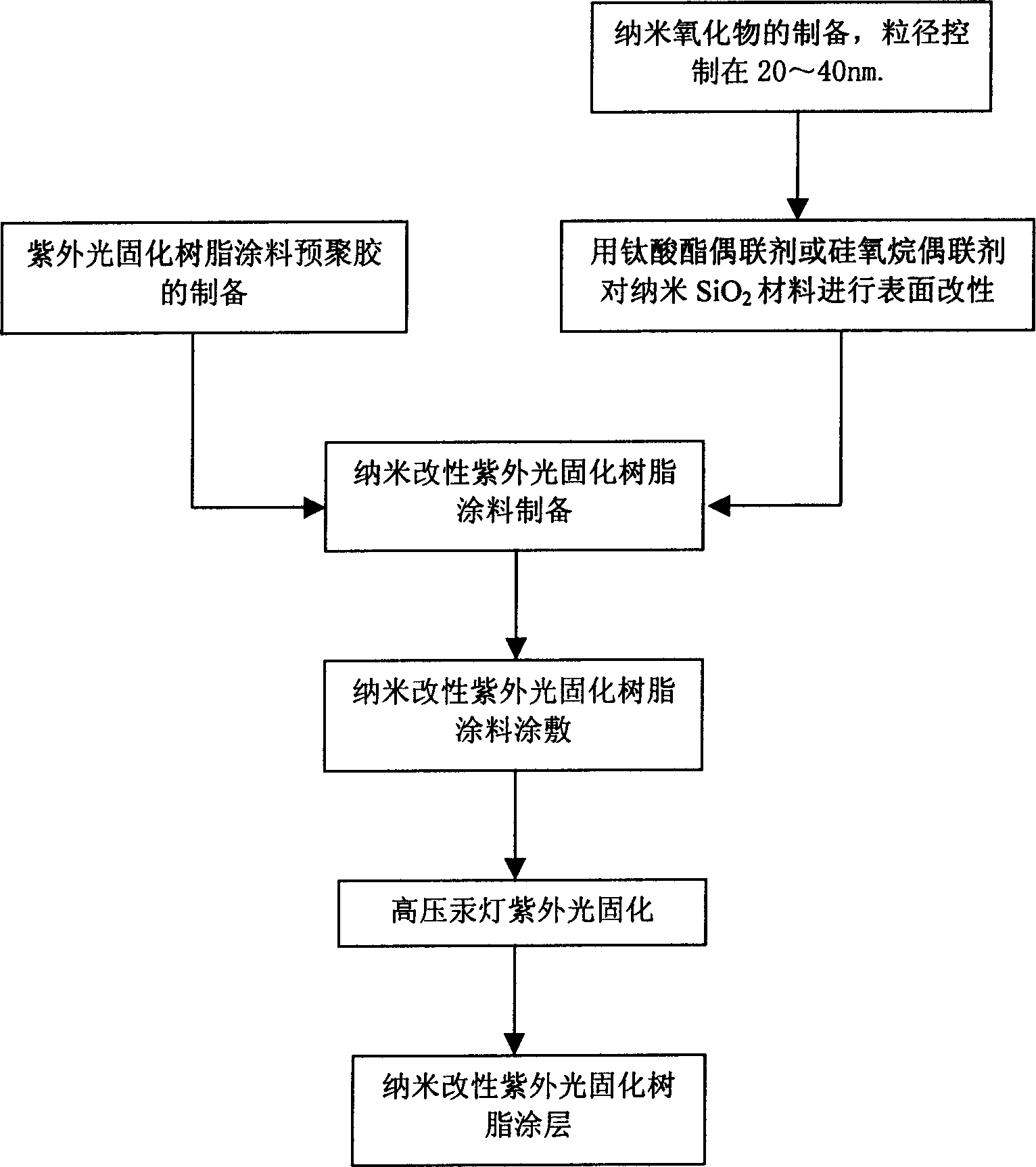

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

[0008] A kind of specific implementation mode of flow process shown in accompanying drawing is:

[0009] The first step: preparation of nano-SiO by sol-gel method 2 , control the calcination temperature at 600-800°C and add polyvinyl alcohol (PEG) or gelatin to control the particle size between 20-40 nanometers;

[0010] The second step: use X-ray diffraction (XRD), transmission electron microscope (TEM), scanning electron microscope (SEM) and Fourier transform infrared spectrometer (FT-IR) to measure the particle size, crystal form and crystal appearance of nanomaterials, The spectroscopic properties of nanomaterials and the dispersion state of nanomaterials in resin coatings;

[0011] The third step: use titanate coupling agent or siloxane coupling agent to nano-SiO 2 Surface modification, using reflux method: drop coupling agent into a three-necked flask filled w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com