Biochip sensor surface carrying polyethylene glycolated nanoparticles

A biosensor and nanoparticle technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of different sensitivity enhancement effects, inability to prevent non-specific adsorption of impurities, and low sensitivity, so as to suppress non-specificity Adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

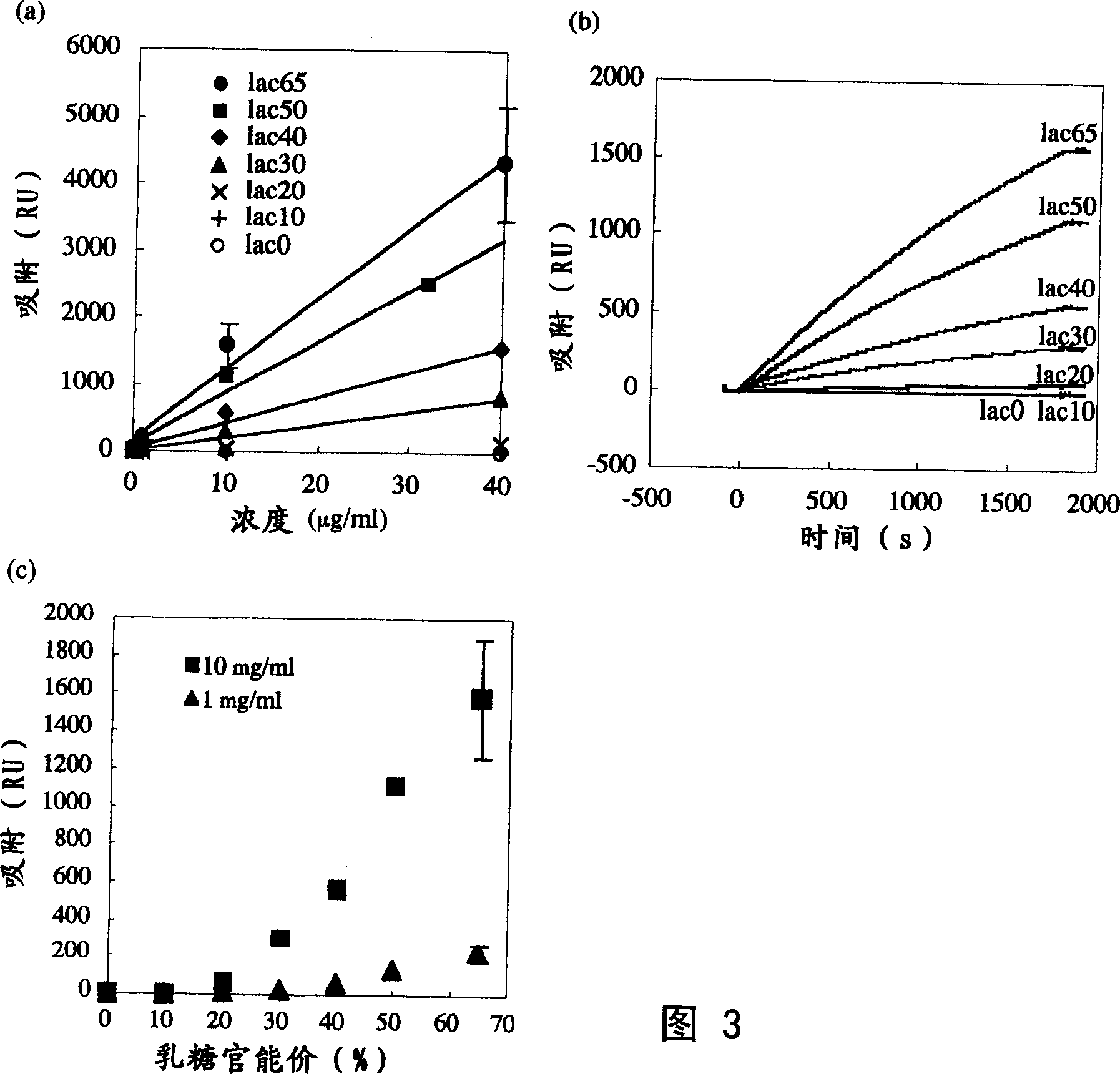

Method used

Image

Examples

preparation example 1

[0094] Preparation Example 1: Preparation method (one) of PEG-modified gold particles:

[0095] Polymer used: Acetal-PEG-SH (Mn=5000)

[0096]

[0097] Acetal-PEG-SH:HAuCl 4 =1 / 6:1 (molar ratio), add relative HAuCl to the aqueous solution mixed in the above ratio 4 10 times the molar amount of NaBH 4 , Colloidal gold adjusted by reduction method. Treat the terminal acetal group with hydrochloric acid at pH 2, reduce it to an aldehyde group, and then react with p-aminophenyl-β-D-lactopyranoside to obtain a colloidal gold aqueous solution modified by lactose-PEG-SH (average particle size : 8.7nm).

[0098] Acetal-PEG-SH was prepared as follows.

[0099]Add 20ml of distilled tetrahydrofuran (THF) and 0.2mmol (0.032ml) 3,3-diethoxyl-1-propanol initiator in the container replaced by argon, then add the equivalent of potassium naphthyl, and stir for 15 minutes , for metallization. Thereafter, 22.7 mmol (1, 135 ml) of ethylene oxide was added, stirred at room temperature fo...

preparation example 2

[0100] make 2.0 x 10 -2 One mmol (100 mg) of PEG-SS-Py was dissolved in 4 ml of distilled water, and 0.1 mmol (15.42 mg) of dithiothreitol was added in a 5-fold molar amount, and stirred at room temperature for 30 minutes. After the reaction, the polymer (hereinafter referred to as PEG5000) was recovered by washing with saturated brine, extracting with chloroform, and reprecipitating with ether. recycled polymer 1 The structure was confirmed by H-NMR, and the terminal SH group was quantified by reacting with 2-pyridyl disulfide (2-PDS). Preparation Example 2: Preparation method of PEG-modified gold particles (two)

[0101] Polymer used: Acetal-PEG-SH (Mn=3200)

[0102]

[0103] (1) Preparation of the polymer used

[0104] According to the reaction scheme I, using the initiator 3,3-diethoxy-1-propanol and the terminator methanesulfonyl chloride, a heterobifunctional PEG with acetal group and methanesulfonyl group was synthesized by anionic polymerization. Then react wit...

preparation example 3

[0116] Preparation Example 3: Preparation method of PEG-modified gold particles (Part 3)

[0117] Polymer used in this example (Acetal-PEG-PAMA):

[0118]

[0119] (According to above-mentioned people such as kataoka, the method described in Macromolecules, 1999, 32, 6892-6894 pages obtains. Use PEG Mw=5000g / mol, PAMA (poly[methacrylic acid (2-N, N-dimethylamino ) ethyl ester]) n=130, m=100) to produce PEGylated CdS semiconductor particles. 1 mL of 2.5 mg / mL auric acid chloride (HAuCl 4 ) aqueous solution and 5 mL of 6 mg / mL acetal-PEG / PAMA block copolymer aqueous solution (NH:Au=8:1) were mixed, and stirred at room temperature for 24 hours. The UV-vis spectrum was measured at predetermined time intervals, and it was confirmed that the peak at 540 nm originating from the gold particles gradually increased, and a colloidal gold particle (fine particle) dispersion was produced without adding a reducing agent. The solution was measured by light scattering (DLS: Dynamic Ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com