Wallpaper and method for producing thereof

A wallpaper and bottom paper layer technology, applied in chemical instruments and methods, paper, papermaking, etc., can solve the problems of difficult sticking, poor three-dimensional sense, and contamination on the surface of wallpaper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

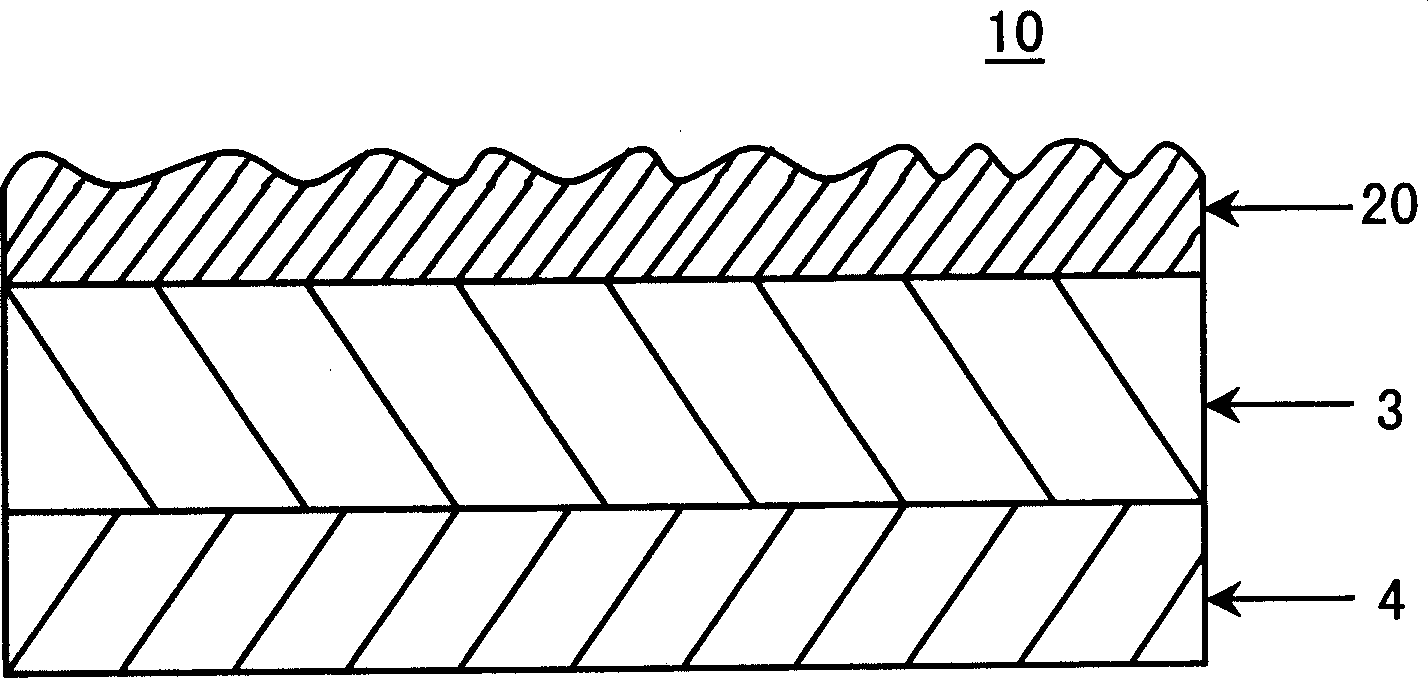

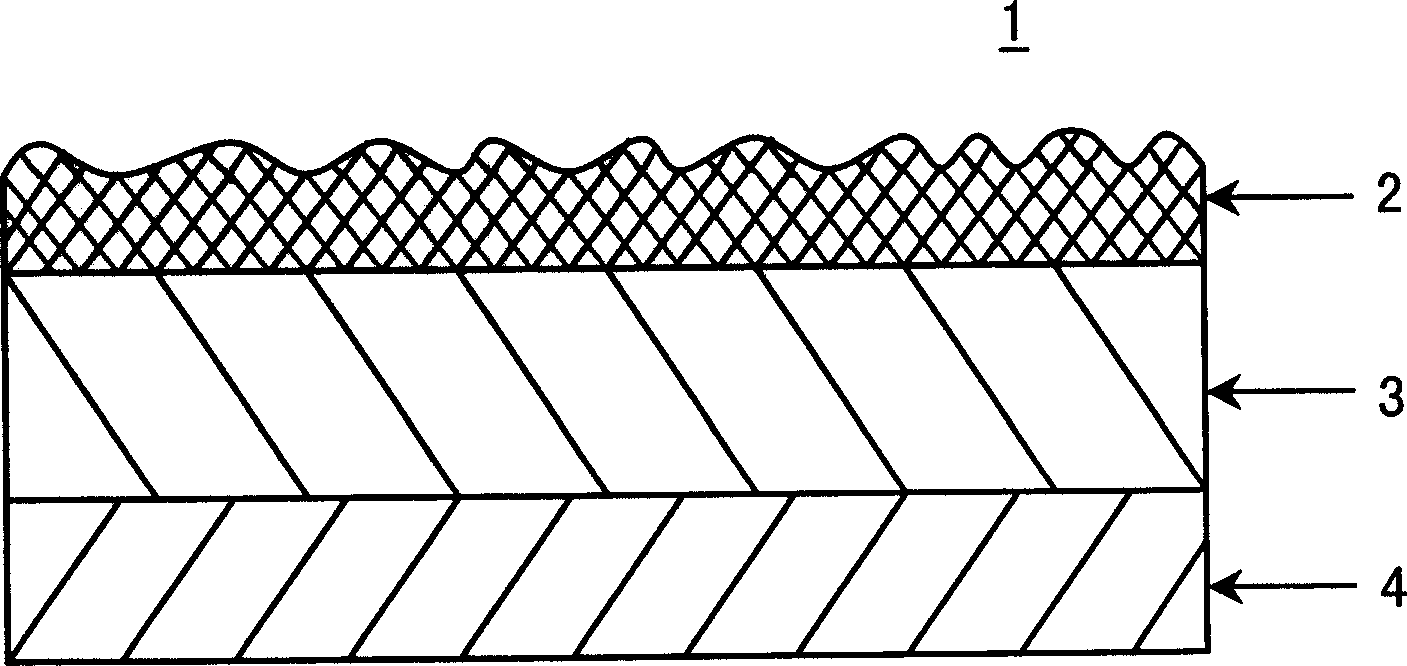

[0048] Below, refer to figure 1 Embodiment 1 of the present invention will be described.

[0049] The wallpaper 10 of the present invention has the following laminated structure: the thermoplastic resin film layer 20 is laminated and bonded on one side of the bulky non-woven fabric layer 3 by a hot-melt method; A polyolefin laminate base paper layer 4 having an extrusion laminated layer of a fusion-bonding polyolefin resin on one side, the extrusion laminated layer being on the inner side (nonwoven fabric layer side), is laminated and bonded by a hot melt method. The other surface of the non-woven fabric layer 3 is connected, and then heat embossing is performed from the side of the thermoplastic resin film layer.

[0050] The non-woven fabric 3 used in the wallpaper 10 of the present invention is not particularly limited, as long as it has softness, flexibility, non-hygroscopicity and bulkiness, it can adopt spunbonded (spunbonded) fabric, jet spray net (spunlace) : Spunlac...

Embodiment 1

[0073] Pulp fibers (NBKP: manufactured by Oji Paper Co., Ltd.) with a fiber length of 0.05 to 5 mm are scattered from a pulp mat forming machine, and the weight per unit area is 45 g / m 2 A layered pad, spray a kind of adhesive aqueous solution, and its composition is: acrylic adhesive (trade name " QET1003 " Japan Zeon company (ZEON Corp.) make) 29.8 mass parts and waterproofing agent (trade name " Asahi Guard" (manufactured by Asahi Glass Co., Ltd.) 0.2 mass part, and the bulk density is 0.075g / cm 3 Air-laid non-woven fabric made of pulp fiber with a thickness of 1.0mm.

[0074] In addition, the polyethylene resin film ("WS-21N" produced by Fusuke Kogyo Co., Ltd., manufactured by Fusuke Kogyo Co., Ltd., the thickness before matting treatment) 21μm, the thickness after matte treatment is 38μm, and the weight per unit area is 19.5g / m 2 ) on the back of the corona discharge treatment, gravure printing was carried out to make a film for the surface layer.

[0075] In addition,...

Embodiment 2

[0079] A polyethylene resin film (" WS-21N" manufactured by Fukusuke Kogyo Co., Ltd., thickness before matting treatment is 21 μm, thickness after matting treatment is 38 μm, weight per unit area is 19.6 g / m 2 ) after corona discharge treatment on the back, gravure printing was carried out to make a film for the surface layer. Moreover, the wallpaper containing the pulp fiber nonwoven fabric was produced by the method similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com