Combining method for heat pipes and radiating fins

A technology of heat dissipation fins and heat pipes, which is applied in the field of combination of heat pipes and heat dissipation fins, can solve problems such as unstable combination of heat pipes and heat dissipation fins, troublesome assembly process of radiators, etc., and achieves improved operation efficiency and convenience, The effect of high-efficiency thermal conductivity and small interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The method for combining heat pipes and cooling fins of the present invention is applied to the manufacture of heat pipe radiators, which can quickly and closely connect the formed heat pipes and cooling fins, and make the heat pipe radiators have high-efficiency heat conduction performance.

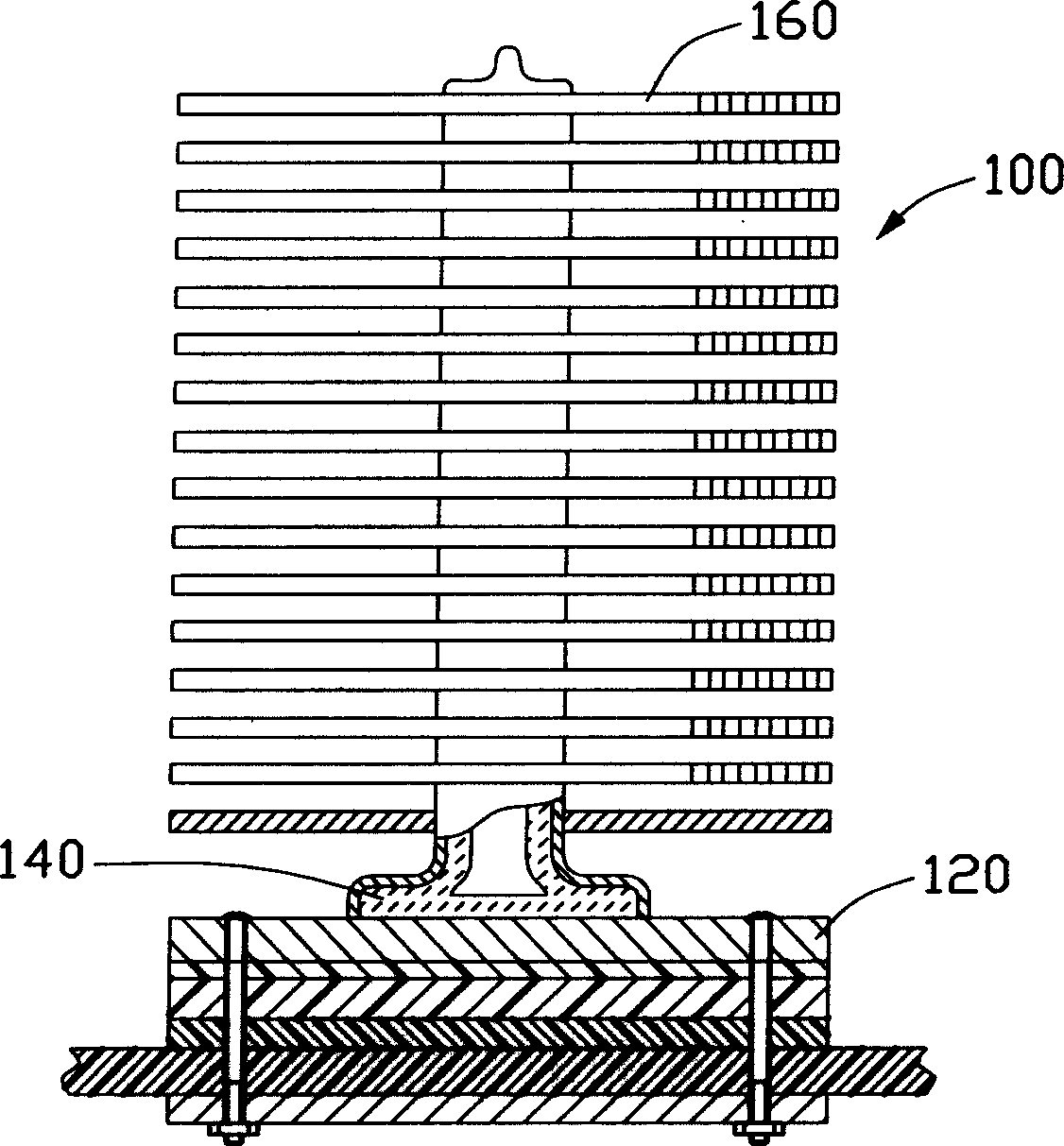

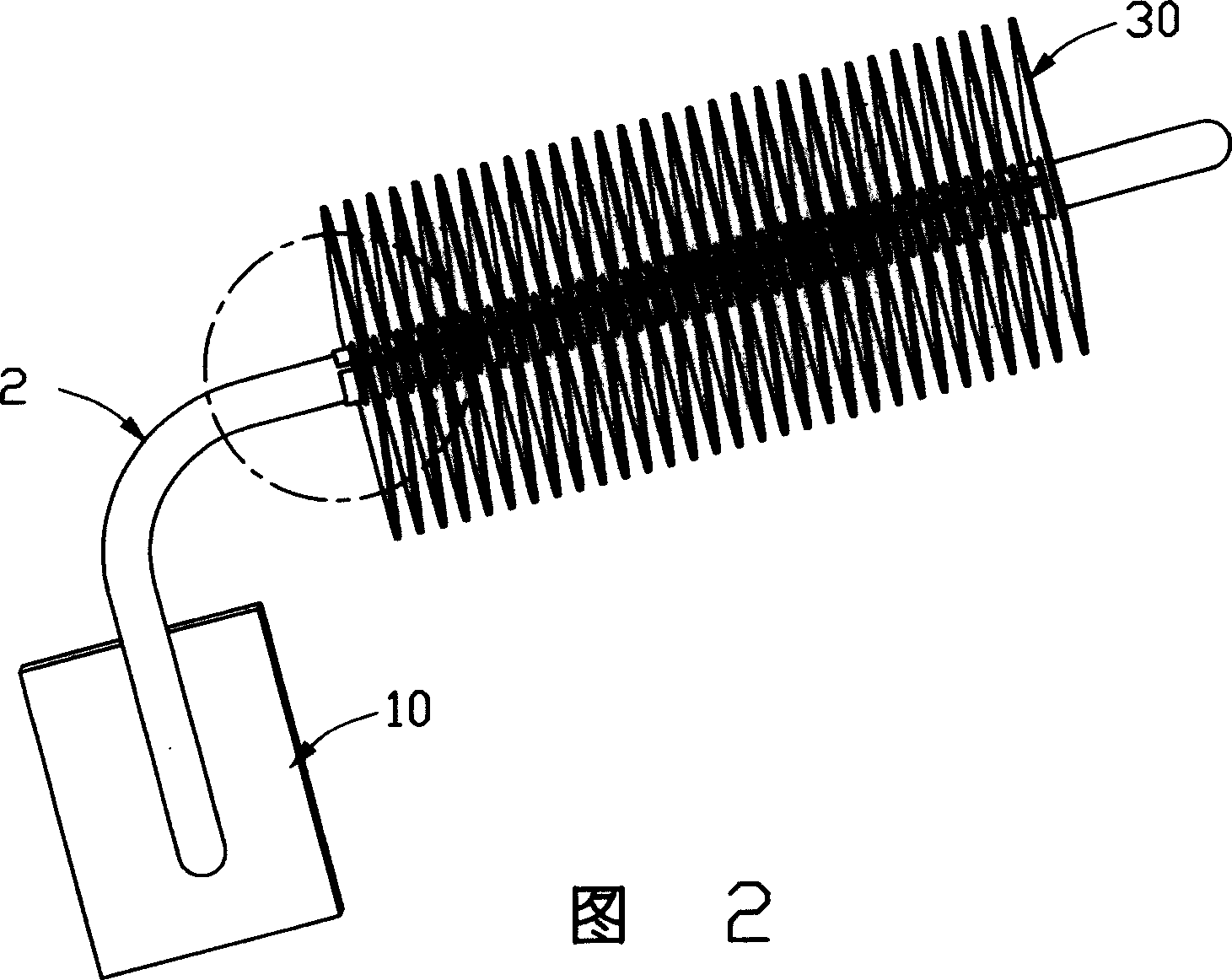

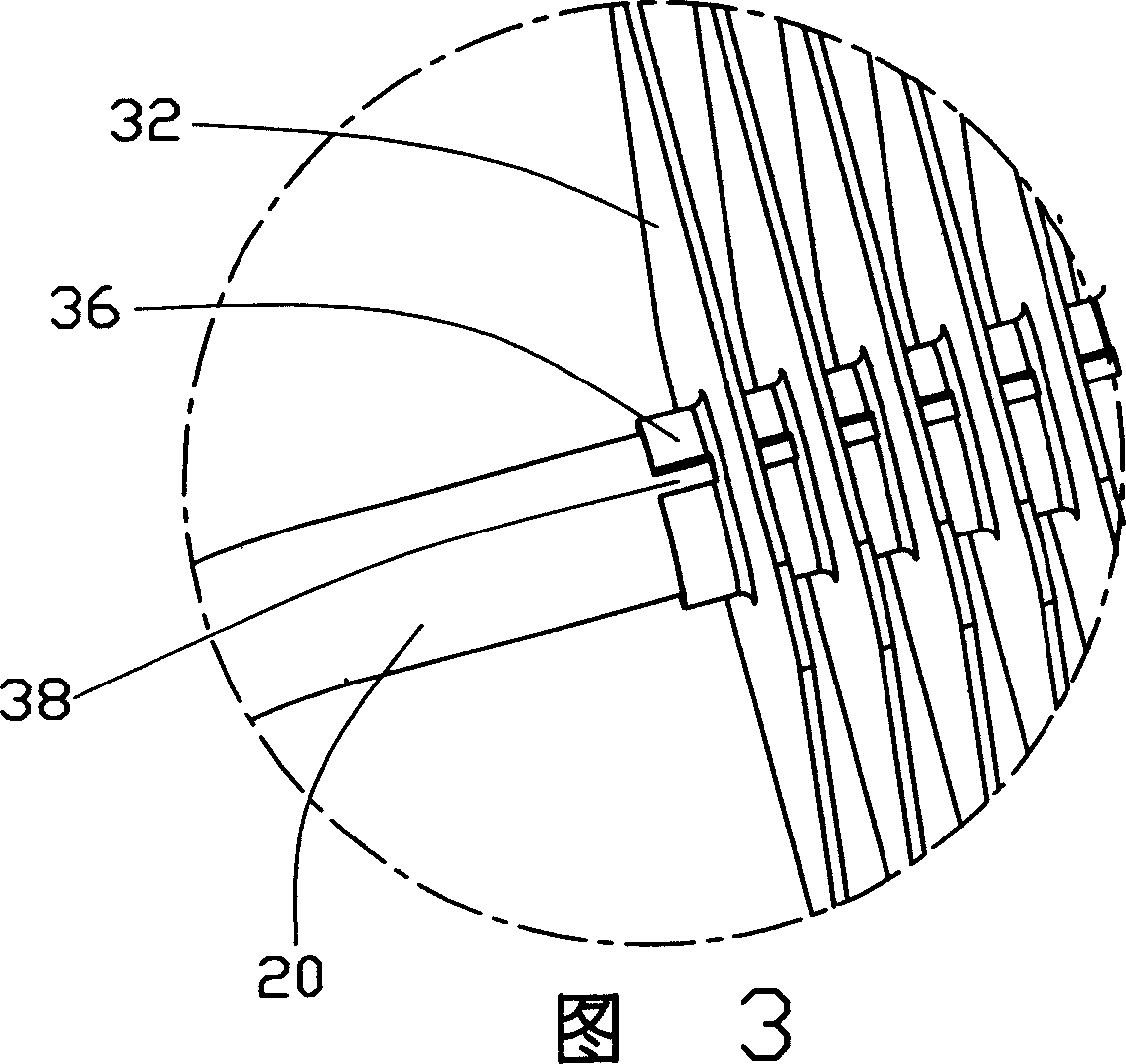

[0016] Please refer to Fig. 2, this heat pipe type radiator 1 has a base 10 which is in contact with heating electronic components such as a central processing unit, at least one heat pipe 20 is horizontally inserted on the base 10, and several heat dissipation fins 30 are parallel at certain intervals. Arranged and threaded on the heat pipe 20 , the heat sink 1 can absorb the heat generated by the heat-generating electronic components from the base 10 , and transfer the heat from the heat pipe 20 to the heat dissipation fins 30 , and then dissipate it. Of course, this heat sink 1 is not limited to the above-mentioned structure. For example, the heat pipe 20 can be inserted vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com