Prepn process of emulsive interpenetrating thermoplastic elastomer

A thermoplastic elastomer and interpenetrating network technology, which is applied in the field of emulsion polymerization to synthesize interpenetrating network thermoplastic elastomers, can solve the problems of low efficiency, low efficiency of crosslinking agent, loss of control of crosslinking density, etc., and achieve crosslinking High efficiency, satisfying repeated processing, and maintaining structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

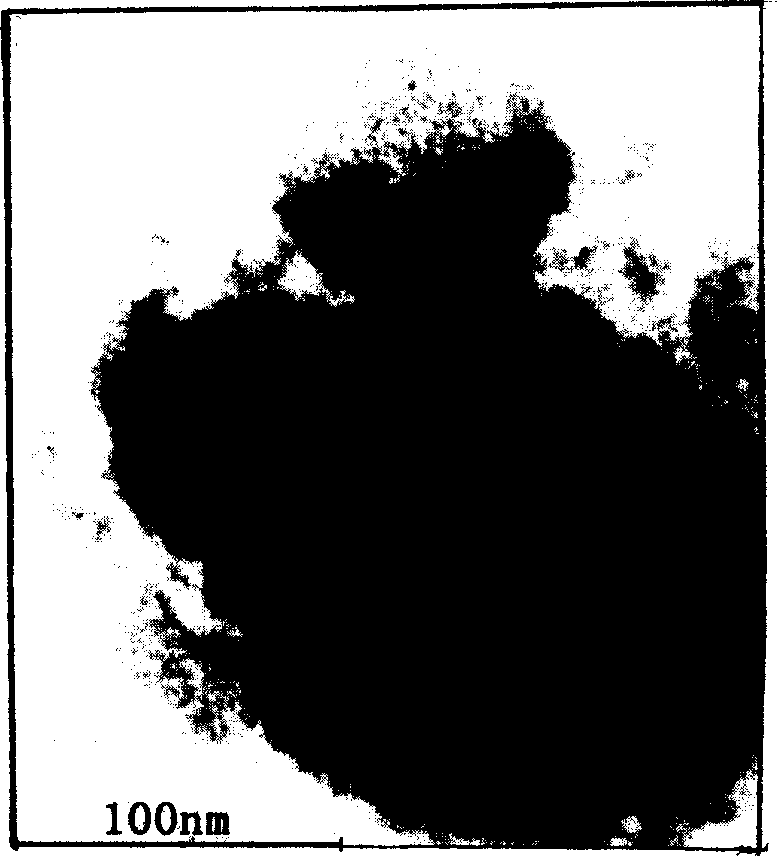

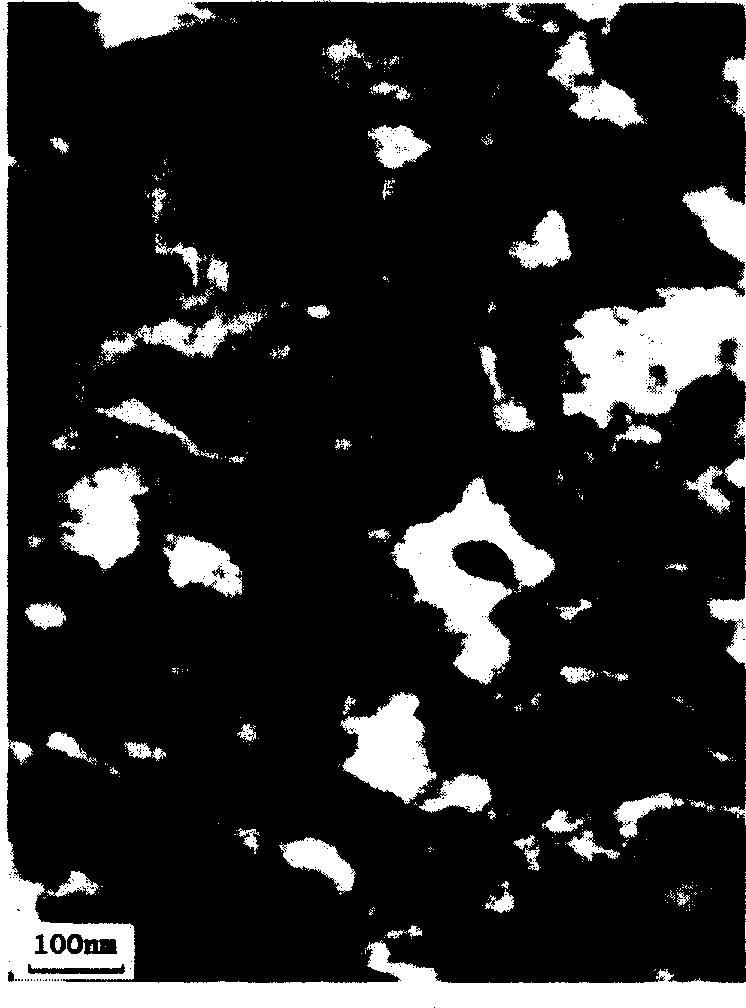

Image

Examples

Embodiment 1

[0031] Add 5.0 g of emulsifier sodium alkyl sulfate (SDS) and 325 ml of deionized water into a 1000 ml three-port reactor, get 250 g of acrylate monomers containing triethylene glycol diacrylate (TEGDA) crosslinking agent, and crosslink The consumption of agent is 0.15% (molar ratio), drops among the reactor, after 20 minutes of passing nitrogen, in the reactor at 50 ℃, slowly add dropwise 0.175g ammonium persulfate and 0.175g sodium bisulfite solution simultaneously , dripping is completed within 1 hour, and then kept at 60°C for 2 hours, and the polymerization is stopped after the conversion rate is greater than 98%. After the solid content is measured, the material is discharged for use.

[0032] In a 1000ml three-port reactor, add 12.5g of seed I (calculated according to the solid content, about 38ml), add 200ml of deionized water, and at a uniform stirring speed, take 237g of the same monomer as the previous reaction, and drop it into the reactor Among them, while adding ...

Embodiment 2

[0035] Add 350ml of deionized water into a 1000ml three-port pressure reactor, add 5.0g of disproportionated abietate potassium and 3.0g of diffusing agent NF into the reactor, and take 250g of a mixture of butadiene and styrene, wherein the ratio of butylbenzene to styrene is 70 / 30 Between 95 / 5, 0.2% (molar ratio) of divinylbenzene (DVB) crosslinking agent is contained in the mixed monomer, drop into the reactor, at a uniform stirring speed, at about 5 ° C , Utilize 0.3 gram of cumene hydroperoxide, 0.04 gram of ferrous sulfate, 0.1 gram of sodium ethylenediamine tetraacetate, 0.2 gram of carved white powder to initiate polymerization, and obtain micro-crosslinked styrene-butadiene rubber seed I emulsion.

[0036] In a 1000ml pressure vessel, weigh 18.8g of the above-mentioned Seed I emulsion (calculated according to the solid content, about 63ml), add 250ml of deionized water, and gradually add 170g of monomer dropwise under stirring, the monomer is completely the same as the...

Embodiment 3

[0040] Add 500 g of deionized water into a 1000 ml three-port high-pressure reactor, add emulsifiers in the reactor, these emulsifiers are potassium stearate 2.5 g, get the mixture of butadiene and acrylonitrile 125 g, wherein butadiene and propylene The ratio of nitrile is at 75 / 25 (weight ratio), wherein contains the divinylbenzene (DVB) linking agent of 0.2% (mol ratio) in the mixed monomer, drops among the reactor, under uniform stirring speed, At about 5°C, the polymerization was initiated by using the cumene hydroperoxide-ferrous sulfate-EDTA-glyphite redox initiation system to obtain a slightly cross-linked nitrile rubber seed I emulsion.

[0041] Add above-mentioned seed I emulsion 6.25g (according to solid content calculation, about 37.5ml) in 1000ml high-pressure reactor, add 500ml deionized water, get the same mixed monomer 118.75g of the previous step, drop in the reactor, and 0.875 g of potassium stearate aqueous solution was added dropwise to the monomer synchron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com