Solid electrolytic capacitor, producing method and apparatus thereof

A technology of solid electrolysis and capacitors, applied in the direction of solid electrolytic capacitors, electrolytic capacitor manufacturing, electrolytic capacitors, etc., can solve problems such as the size of solid electrolytic capacitors 1 becoming larger, and achieve elimination of size increase, elimination of possibility, and reduction of internal resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described as follows:

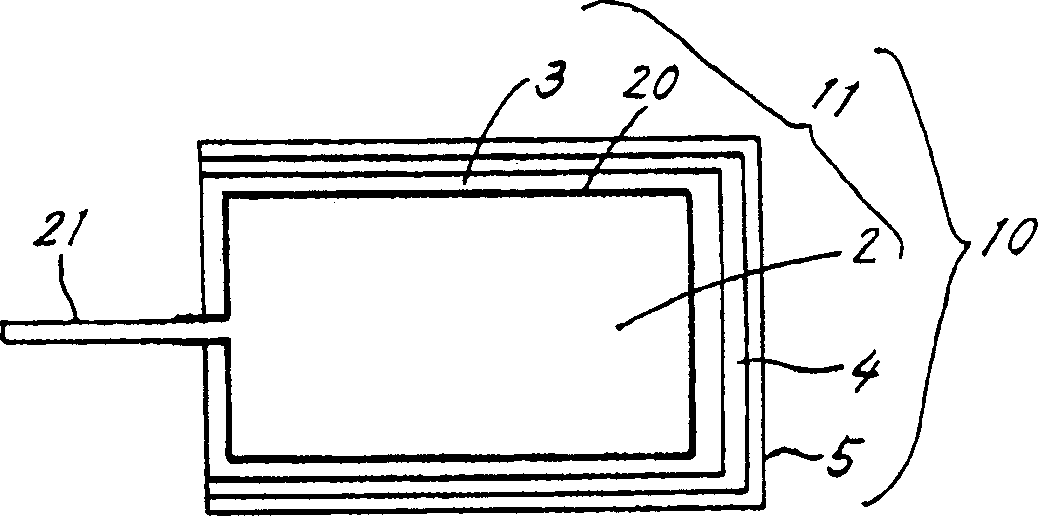

[0036] 1. Example of manufacturing method

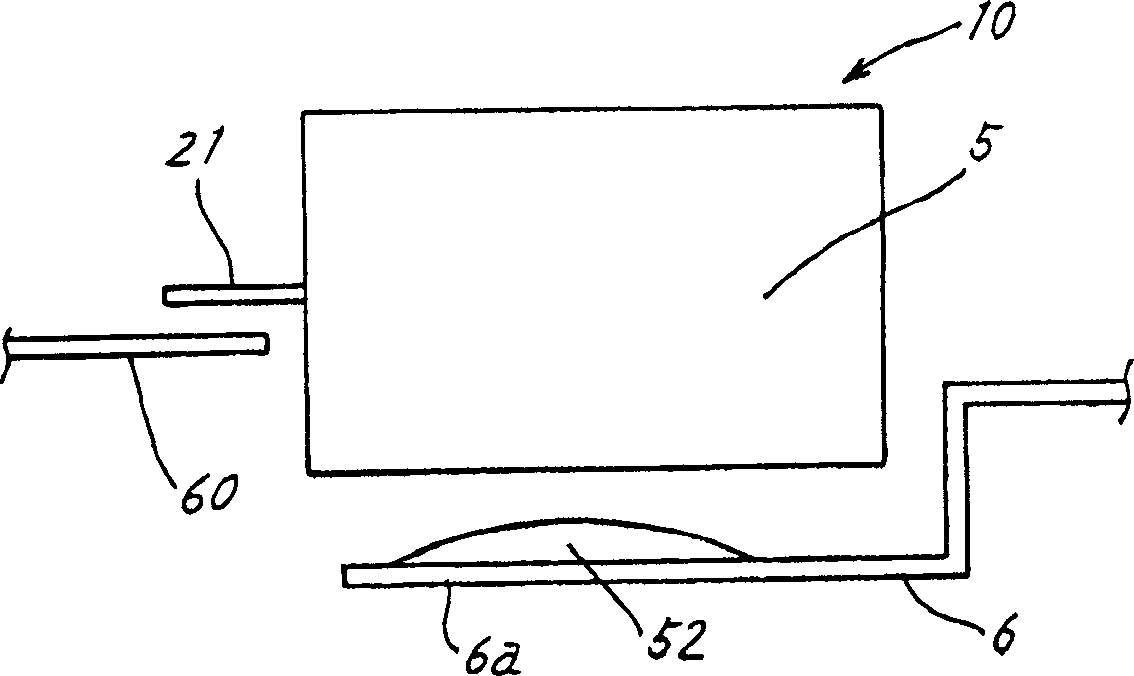

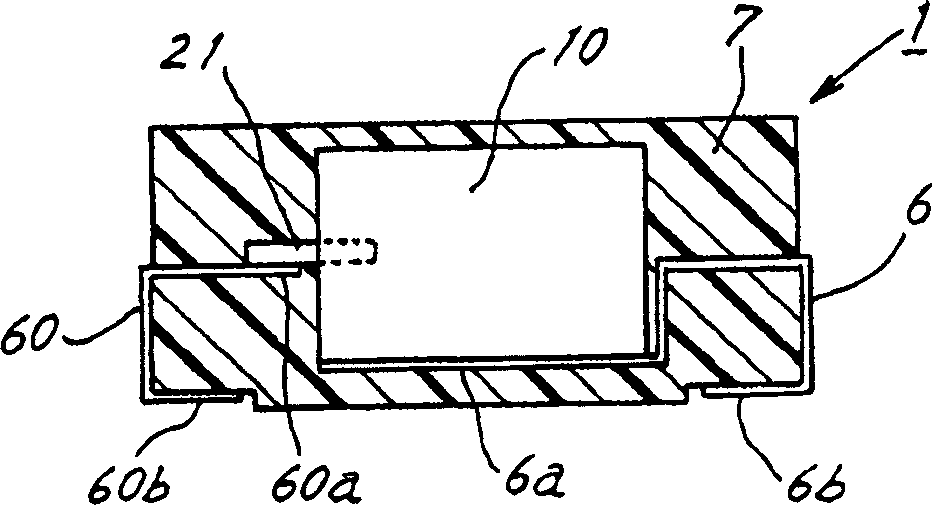

[0037] Referring to Fig. 1, the manufacturing method of the chip type solid electrolytic capacitor according to the present invention comprises: connecting the anode lead wire 21 to the anode body 2 made of valve metal such as Ta, Al or Nb, on the surface of the anode body 2 Electrolytic oxidation treatment is used to form a dielectric oxide film 20, and MnO is used on the oxide film 20 2 Solid conductive substances such as conductive organic compounds form the cathode layer 3 to make the capacitor core 11 . Afterwards, a carbon layer 4 is applied to the cathode layer 3 of the capacitor core, and a silver paste layer 5 is applied to the carbon layer 4 to form a capacitor body 10 . As shown in FIG. 2 , subsequently, the lead frame 6 is connected to the silver paste layer 5 with silver adhesive 52 , and the lead frame 60 is soldered to the anode lead wire 21 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com