Refractory hard metals in powder form for use in the manufacture of electrodes

A hard alloy, high melting point technology, applied in nanotechnology, carbon compounds, metal borides, etc. for materials and surface science, can solve problems such as high melting temperature and difficult material forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

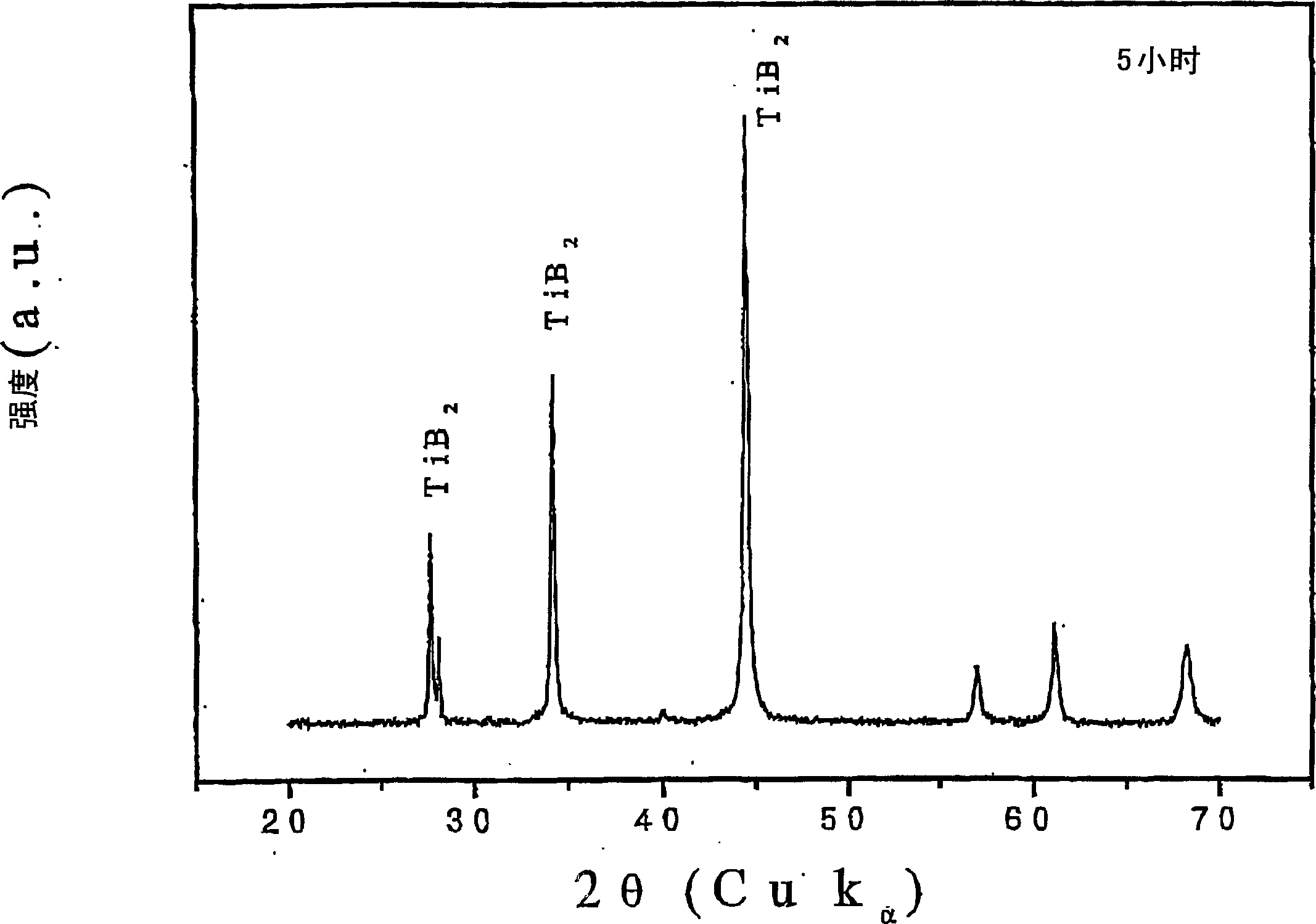

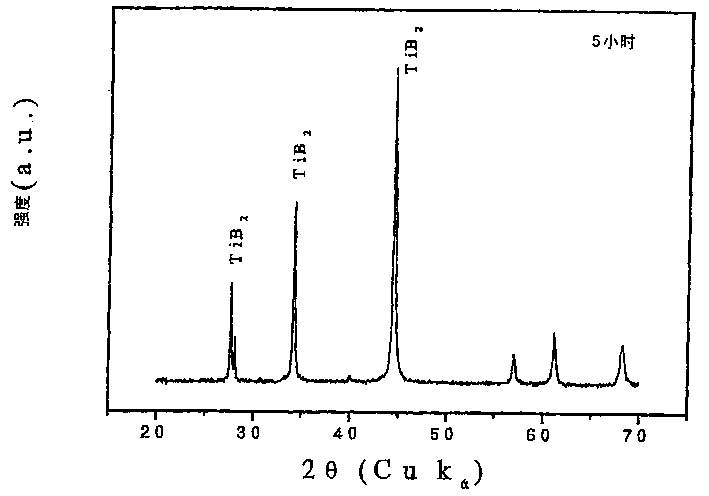

[0030] With a SPEX 8000 (trademark) vibratory ball mill operating at about 17 Hz, 3.45 g of titanium and 1.55 g of boron were ball milled in a hard steel crucible at a ball / powder mass ratio of 4.5:1 to obtain TiB 2 powder. This operation was performed under a controlled argon atmosphere to prevent oxidation. Close the crucible and seal with a rubber O-ring. After high-energy ball milling for 5 hours, TiB was formed 2 structure, as shown in the X-ray diffraction pattern in the accompanying drawings below. TiB 2 The structure of is a hexagon with pitch P6 / mmm(191). The particle size is between 1-5 μm and the crystal size determined by X-ray diffraction is about 30 nm.

Embodiment 2

[0032] TiB was produced following the procedure described in Example 1 and under the same operating conditions, except ball milling was carried out for 20 hours instead of 5 hours 2 powder. The powder obtained was similar to that obtained in Example 1. But the crystal size is small (about 16nm).

Embodiment 3

[0034] Except for ball milling titanium and graphite, TiC powder was prepared according to the steps described in Example 1 and the same operating conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com