Modification method for anode activated charcoal of ultracapacitor

A technology of supercapacitors and modification methods, applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of narrow electrochemical window, affecting the weight specific energy characteristics of carbon-based supercapacitors, and low capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

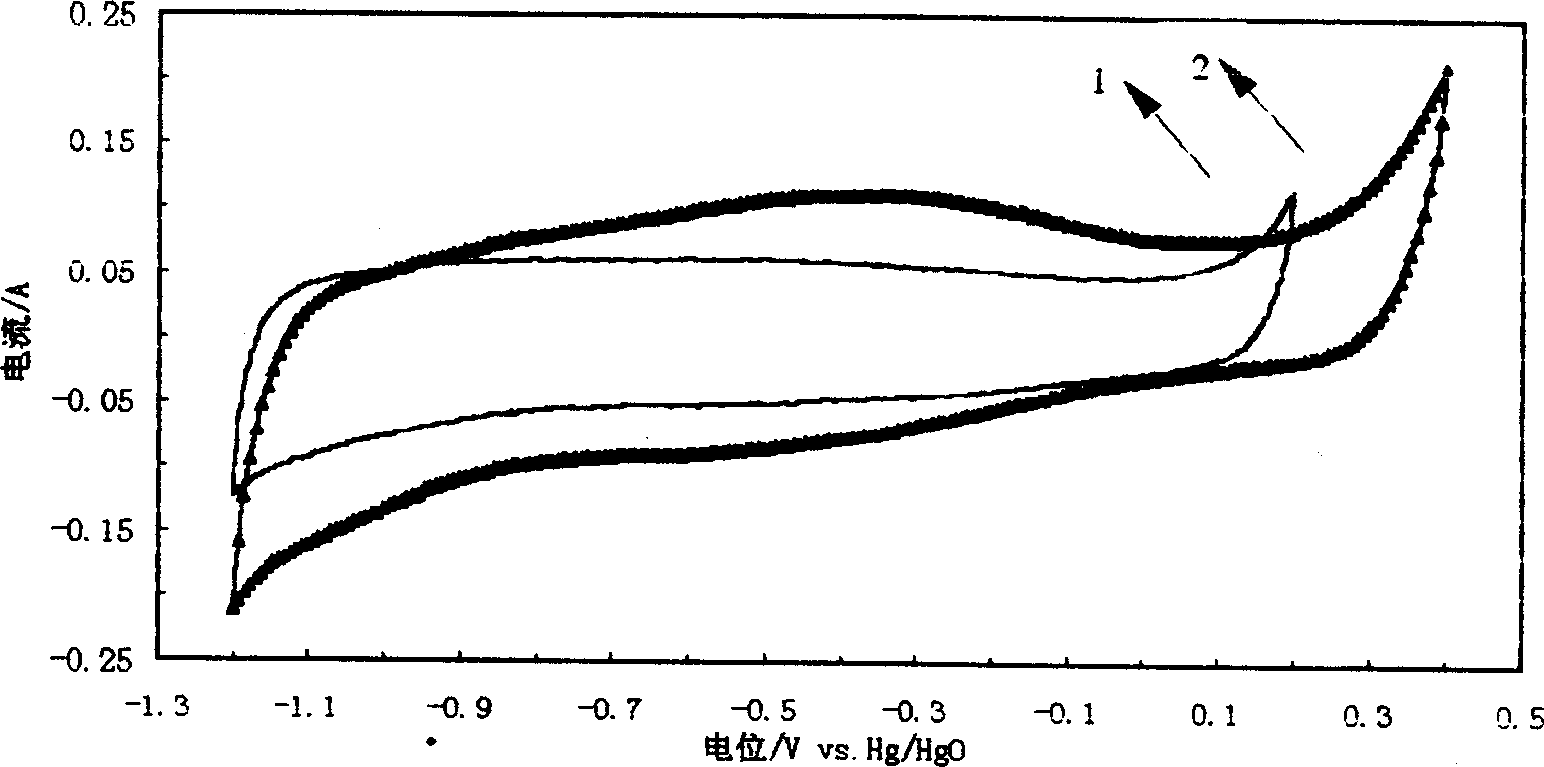

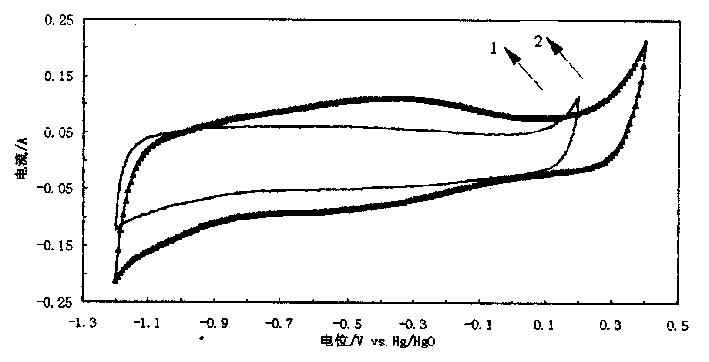

Image

Examples

Embodiment Construction

[0008] Use one of the above schemes to modify the activated carbon material for the positive electrode of the supercapacitor. The specific surface area of the activated carbon used in the experiment is 1000-1500m 2 / g, the particle size is 200-300 mesh, and it has been pre-treated with sulfuric acid and nitric acid before mixing the paste.

[0009] At room temperature, pretreated activated carbon was mixed with 0.05 mol / l Co(NO 3 ) 2 Vacuum impregnation in the solution at 40°C for 3 hours, suction filtration, and then adding an excess of 9mol / l KOH solution for immersion and alkalization for 1 hour, at this time a layer of nano-scale Co(OH) was deposited in the micropores of the activated carbon. 2 The modified layer was suction-filtered until the pH was less than 7.5, and dried at 100° C. for 6 hours to complete the cobalt modification.

[0010] The activated carbon modified by impregnating cobalt was mixed with 3mol / l Ni(NO 3 ) 2 and 0.09mol / l Co(NO 3 ) 2 Vacuum impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com