High conductive copper-steel composite cast cooling wall of blast furnace

A copper-steel composite and cooling stave technology, which is applied in cooling devices and other directions, can solve the problems of limited service life, insufficient cooling capacity, and low service life of cast steel staves, and achieve comprehensive performance improvement, carbon content reduction, and toughness improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

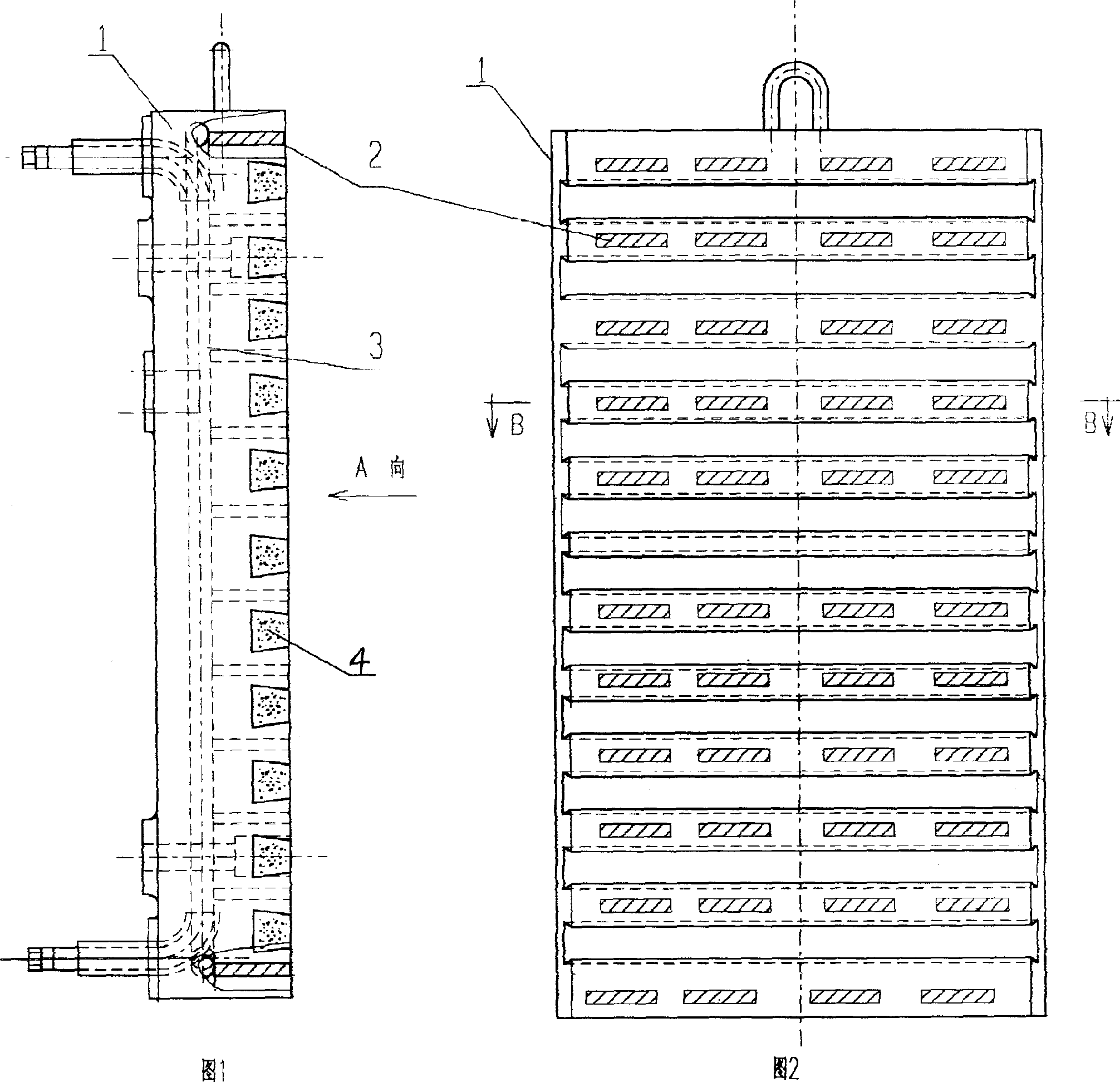

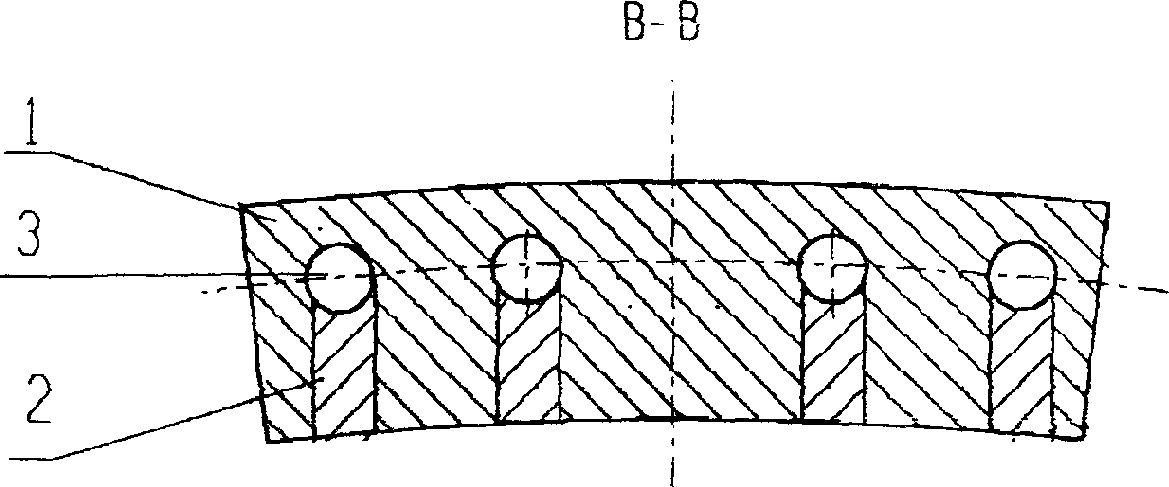

[0035] Figure 1, Figure 2, image 3 As shown, the inlaid and cast copper parts (2) are arranged in rows and columns, and are welded together with the water pipes (3) to form a heat conduction system with high thermal conductivity. (4) is inlaid cast refractory brick or refractory pound , the principle is as mentioned above. Other conventional structures are specifically designed according to the type of blast furnace. The composition of the stave body (1) micro-composite low-carbon steel is: wt%

[0036] Fe: 99.22~98.57% C: 0.15~0.25%

[0037] Si: 0.20~0.40% Mn: 0.30~0.60%

[0038] P: ≤0.04 S: ≤0.04

[0039] V / Ti / Nb: 0.05~0.10

Embodiment 2

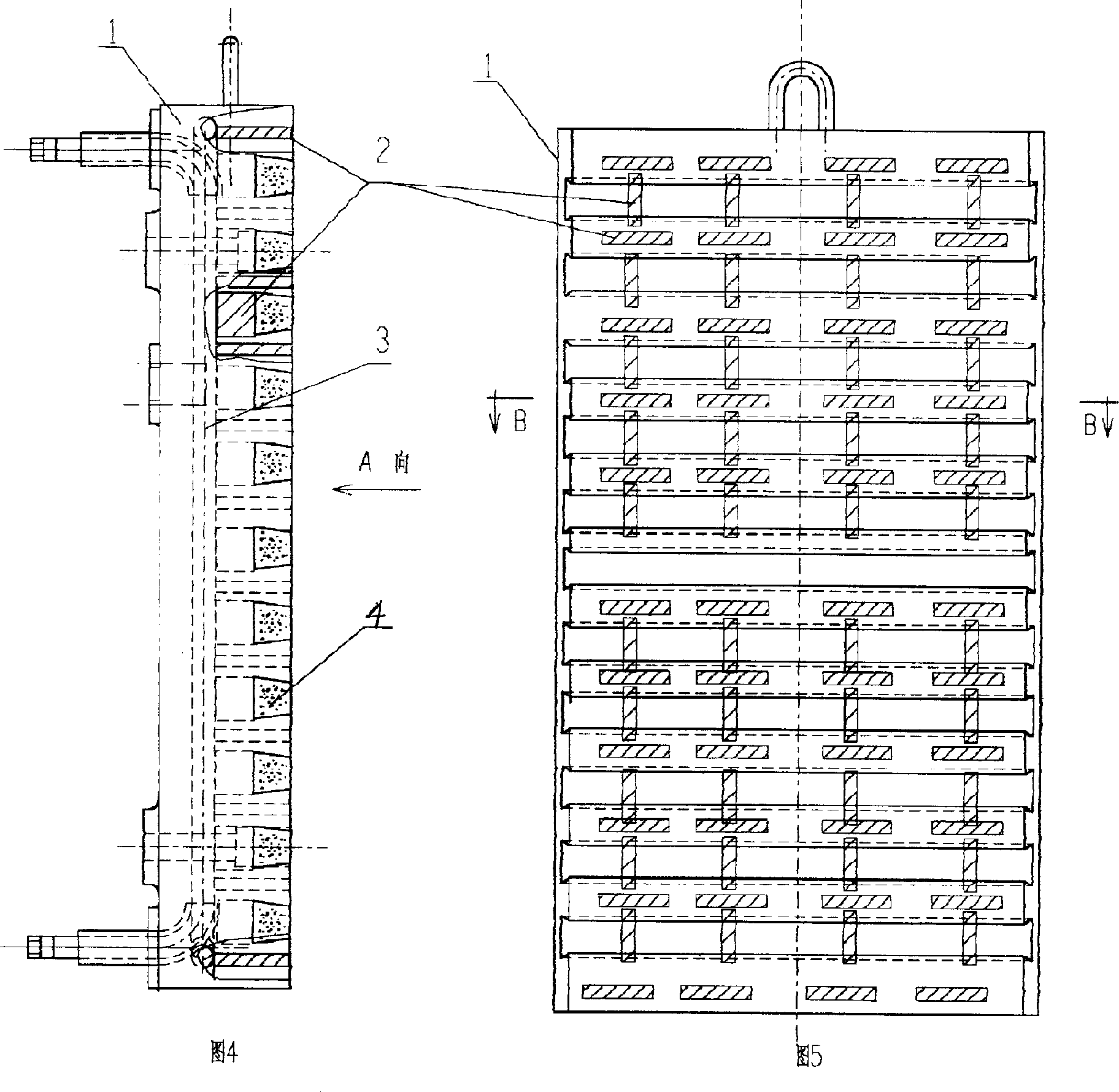

[0041] Figure 4, Figure 5, Figure 6 As shown, the composition of the stave main body (1) micro-alloyed chemical steel is as in Example 1. Inlaid and cast copper pieces (2), the inlaid structure increases the copper piece (2) with a width parallel to the cooling water pipe on the basis of embodiment 1, the cold end is connected with the water pipe (3), and the hot end is connected with the bottom of the dovetail groove In the same way, (4) is an inlaid cast refractory brick or refractory pounding material. Further improve the cooling capacity of the stave.

Embodiment 3

[0043] Figure 7, Figure 8, Figure 9 As shown, the cold surface of the stave is the stave body (1), and its material is microalloyed steel and its composition is as in Example 1. The rib arms of the stave dovetail are all inlaid and cast copper pieces (2). (3) is a cooling water pipe, and (4) is an inlaid cast refractory brick or refractory pounding material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com