Exposure energy predicting method

A technology of exposure energy and energy compensation, which is applied in the field of photolithography technology, can solve the problem of being unable to predict the exposure energy of new products, and achieve the effect of reducing variation and accurate exposure energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

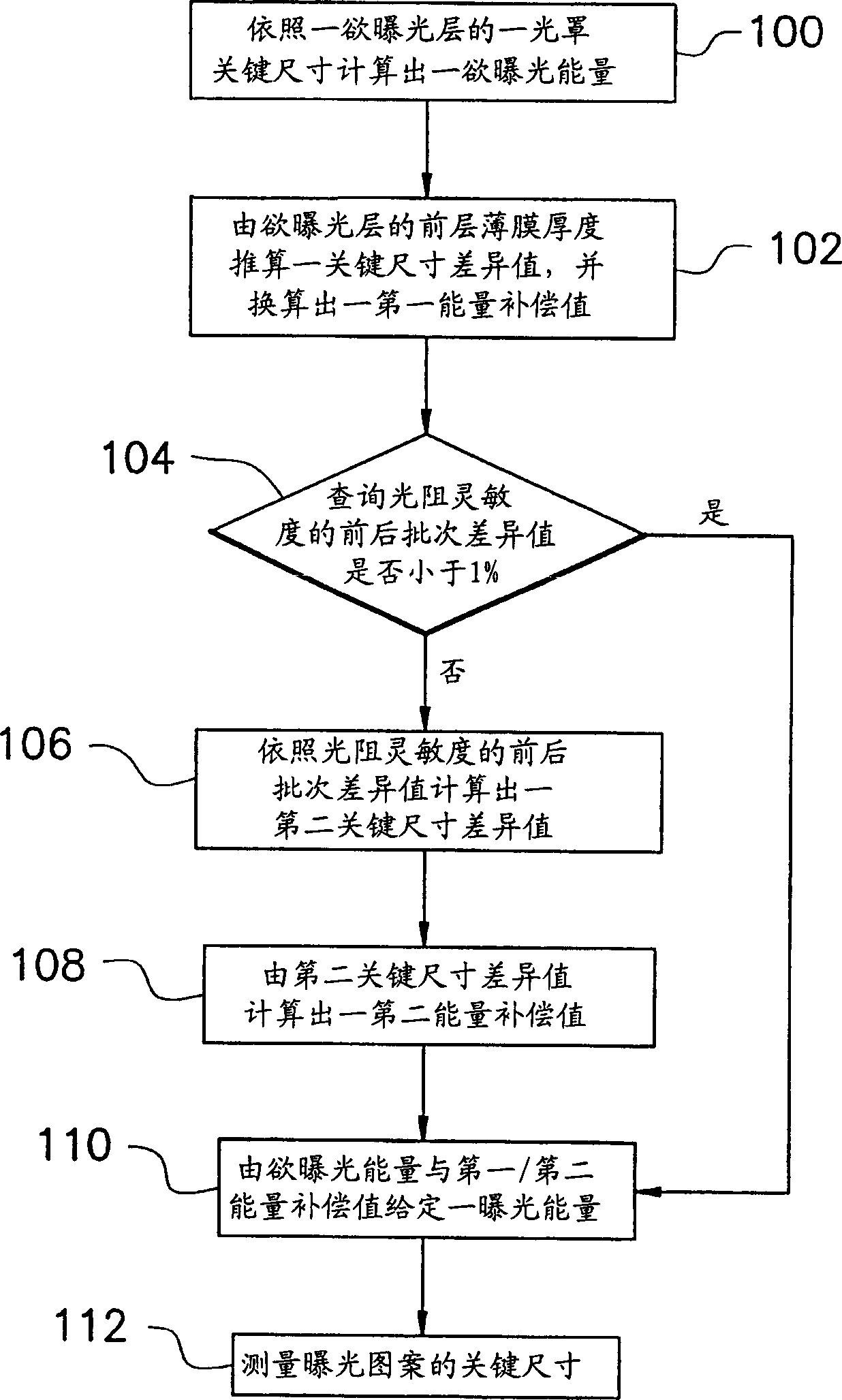

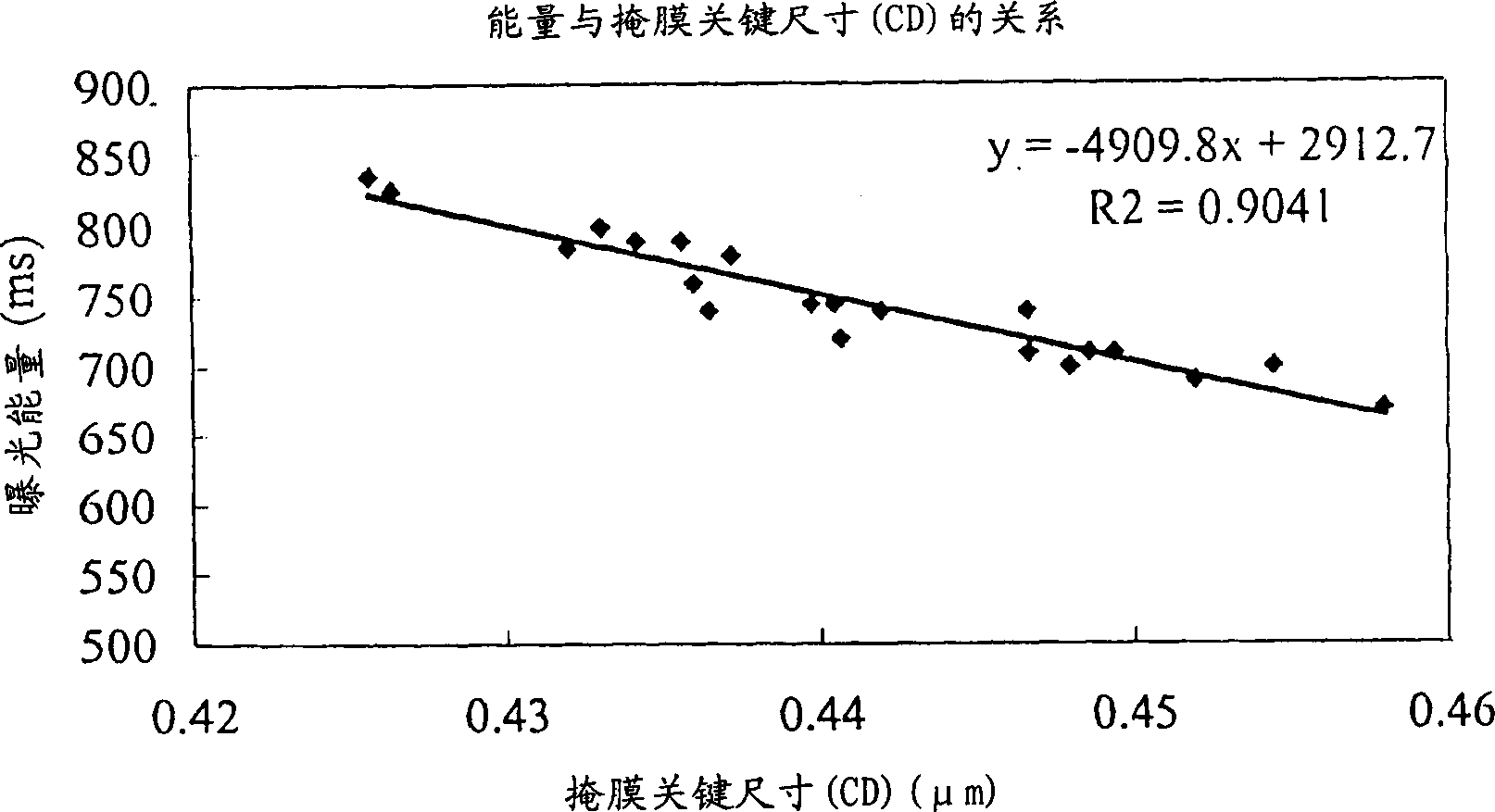

[0018] figure 1 Shown is a flowchart of a method for predicting exposure energy according to a preferred embodiment of the present invention; figure 2 Shown is the linear regression relationship between the critical size of the mask and the exposure energy.

[0019] Please refer to figure 1 The method for predicting exposure energy in this embodiment is to firstly calculate a desired exposure energy according to a critical dimension of a mask of a layer to be exposed (step 100 ). For the method of calculating the energy to be exposed, please refer to figure 2 , figure 2 It is to make a linear regression graph of the historical data of the key size of the mask and the exposure energy, wherein the abscissa is the size of the key size of the mask head, and the ordinate is the value of the exposure energy. Therefore, substitute the mask critical dimension of the layer to be exposed into figure 2 The linear regression equation in can obtain an exposure energy value, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com