Process for producing alpha-sulfo-fatty acid alkyl ester salt

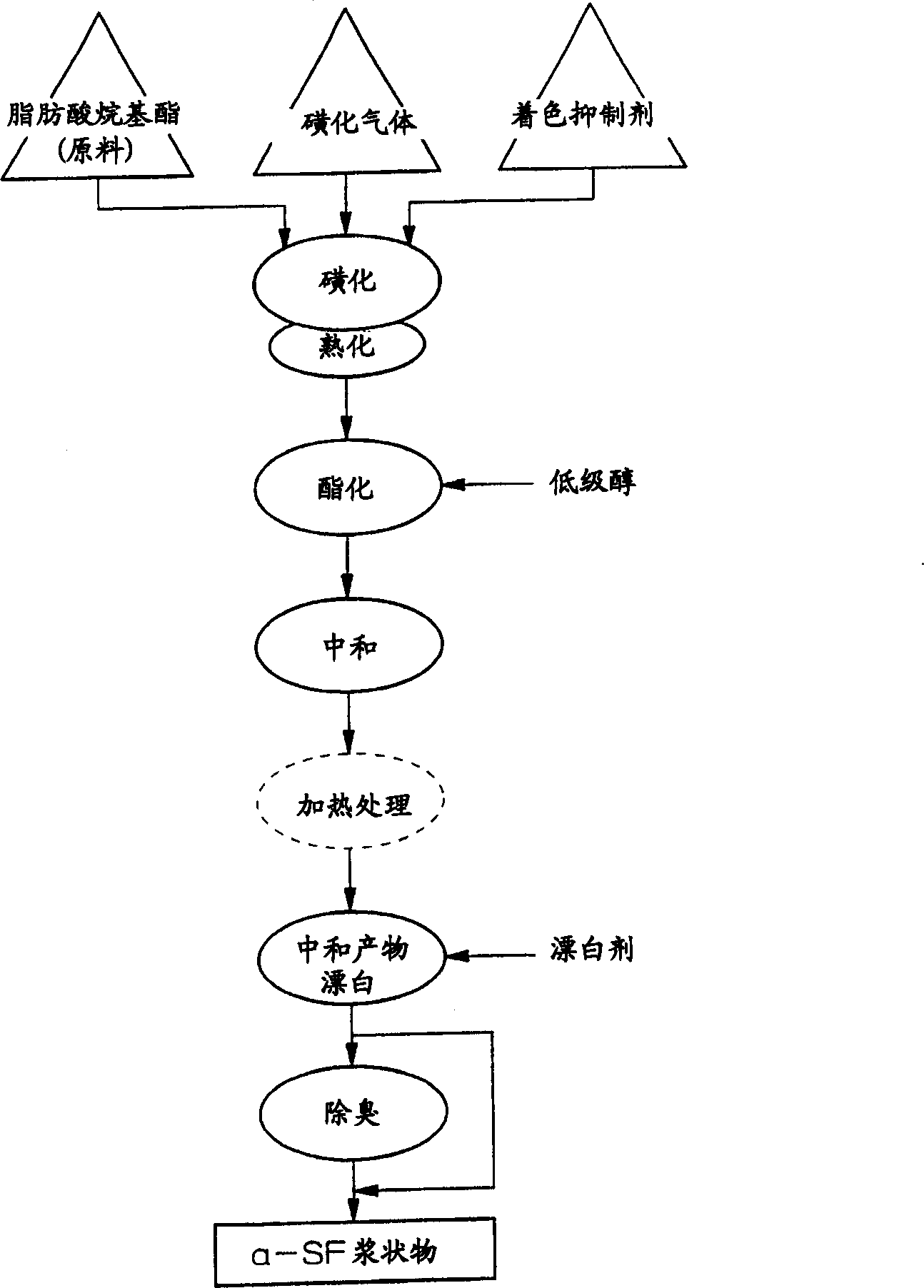

A technology of sulfo fatty acid alkyl esters and fatty acid alkyl esters, which is applied in the field of preparation of α-sulfo fatty acid alkyl ester salts, and can solve problems such as unsatisfactory effects, limited composition of detergent compositions, and complicated preparation processes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

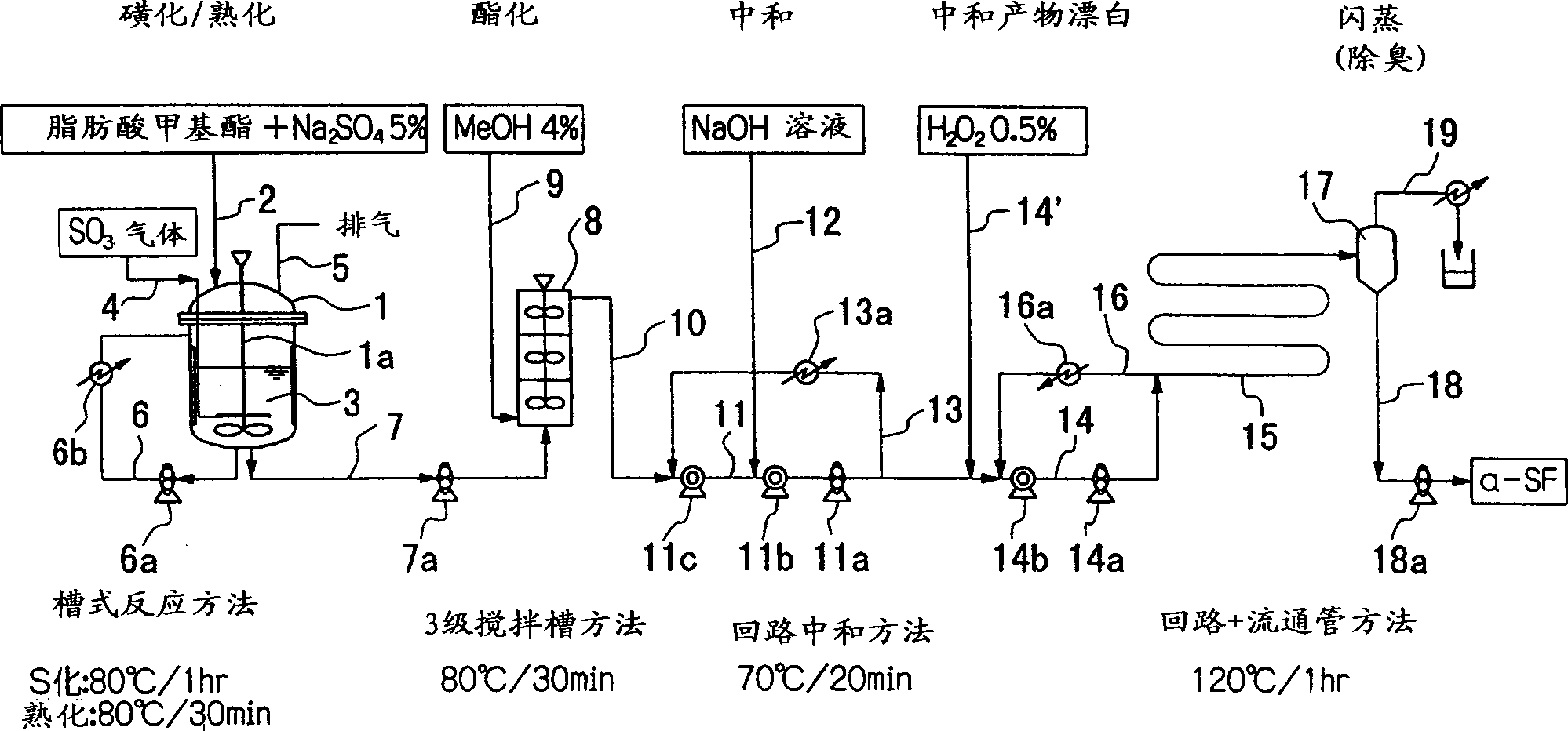

[0158] exist figure 2 [alpha]-Sulfo fatty acid alkyl ester salts were prepared in the pilot plant shown.

[0159] The raw materials used are fatty acid methyl esters obtained by esterification and distillation of palm kernel oil, coconut oil, and palm oil (trade names: Pastel M-14, Pastel M-16, Pastel M-180 (manufactured by Lion Oleochemical)) , After mixing in the required ratio, then undergo hydrogenation treatment to reduce its iodine value and purify the product. The raw material used in this example is a mixture of Pastel M-14 and Pastel M-16 in a weight ratio of 2:8.

[0160] The hydrogenation treatment was carried out by a conventional method, the addition amount of the hydrogenation catalyst SO-850 (trade name, manufactured by Sakai Chemical Co., Ltd.) was 0.1% by weight of the fatty acid methyl ester, and the reaction conditions were 170° C. for 1 hour. After hydrotreatment, the catalyst was removed by filtration.

[0161] The properties and carbon chain distribut...

Embodiment 2~4

[0200] Further, when the product was stored in a constant temperature room at 40° C. for one month, and then evaluated in the same manner as above, the evaluation result did not change.

[0201] Under the conditions shown in Table 3, the experiment was carried out in the same manner as in Example 1. Only Example 3 and Example 4 were subjected to the deodorization step. The results are shown in Table 3 together.

[0202] When evaluating the odors of Examples 2, 4 and Comparative Examples 1 to 3 in the same manner as in Example 1, immediately after the preparation was completed, the results of each product were △, and the results after one month were also △. No change. In addition, when the odor before and after the deodorization step of Examples 3 and 4 was evaluated in the same manner as in Example 1, the same evaluation as in Example 1 was obtained for each product.

[0203] It can be proved from Table 3 that the coloring inhibitor can improve the color tone, and even if...

Embodiment 10

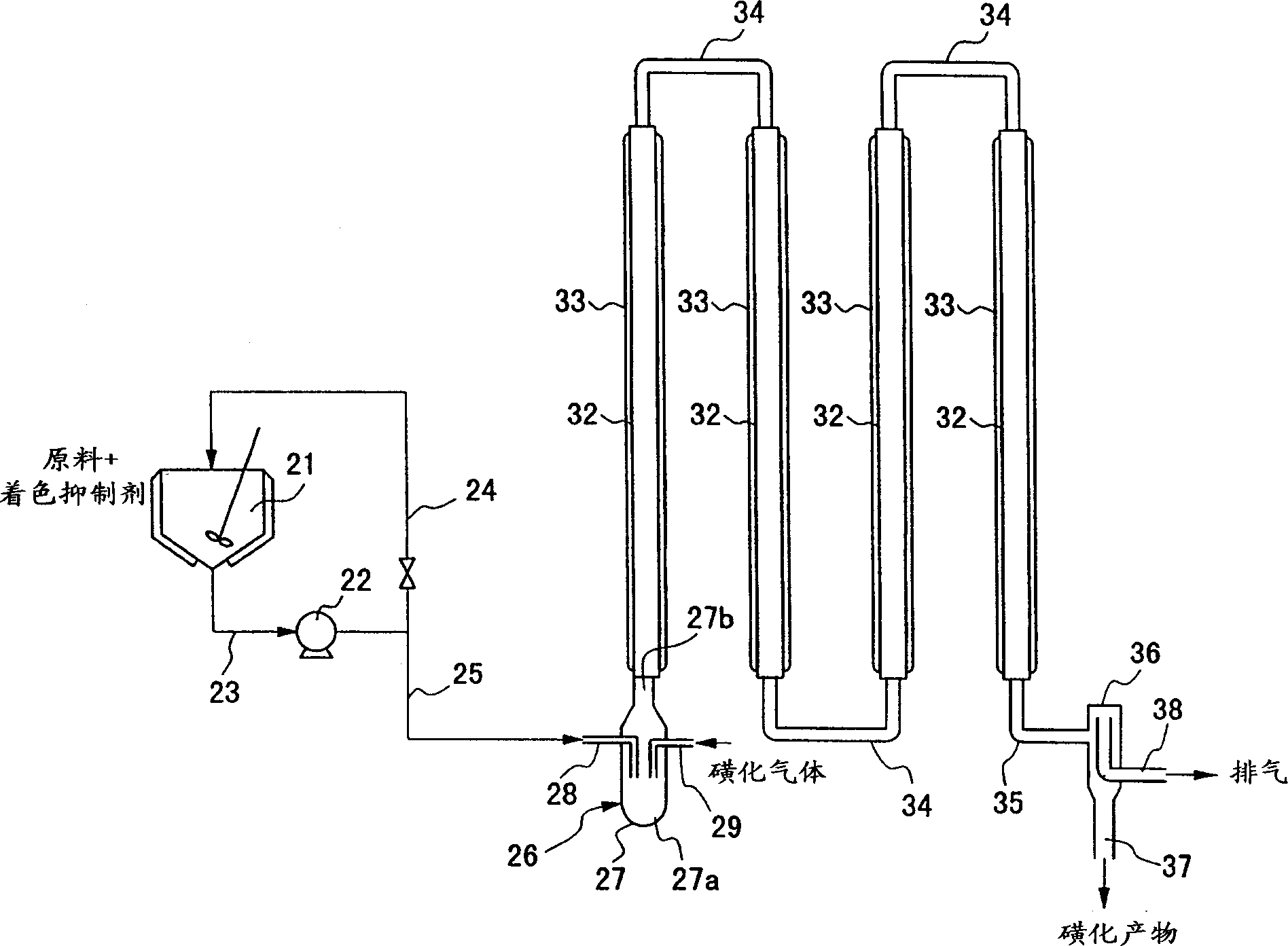

[0212] use image 3 The shown tubular gas-liquid mixed phase flow-through reactor (pseudo-membrane reactor) replaces the tank reactor 1 for the sulfonation reaction.

[0213] A jacketed reaction mixer with a volume of 100 ml was used as the introduction part 26 . As the jacketed reaction tube 32 , four pipes with an inner diameter of 13.8 mm and a length of 2 m made of stainless steel SUS316L were arranged in parallel. These pipes are connected to each other by a connection pipe 34 having an inner diameter of 13.8 mm and a length of 1 m.

[0214]In the stirring tank 21, put into except the iodine value 0.05, all the other same raw material fatty acid methyl esters shown in Table 2, coloring inhibitor Glauber's salt (5% by weight of raw material), be heated to 50 ℃ then, make Glauber's salt in the liquid Evenly disperse in the phase, start the pump 22, and make the mixture return to the stirring tank 21 through the circulation pipe 24, so as to improve the mixing property of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com