One-step molding technology and device for spherical soldering tin

A molding device and solder ball technology, applied in the direction of welding medium, manufacturing tools, welding equipment, etc., can solve the problems of difficulty in meeting the refinement of IC packaging technology, increasing cleaning and drying processes, and easy to produce tolerances, etc. Strong adaptability, high one-time forming rate and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

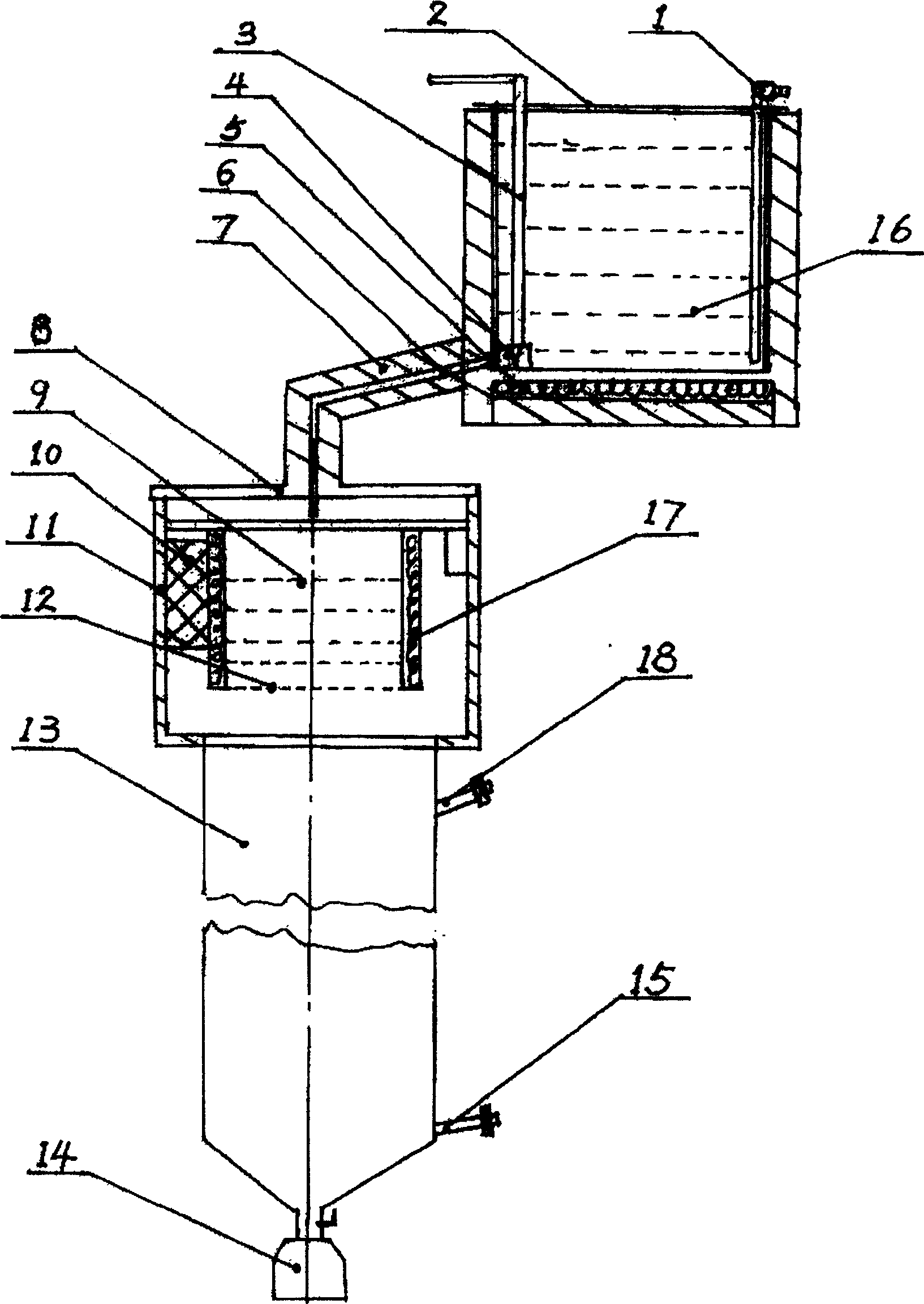

Image

Examples

Embodiment 1

[0029] Utilize above-mentioned molding device, adopt the alloy that raw material is 63%Sn, 37%Pb, prepare solder ball according to the following steps:

[0030] (1) Alloy melting: Put the commercial 1#Sn and 1#Pb ingots in proportion or qualified 63Sn37Pb alloy ingots into the electric heating melting pot for heating and melting, then stir them evenly until the alloy temperature reaches 360°C±10°C, prepare Put the alloy liquid into the "liquid particle forming machine".

[0031] (2) Electromechanical integration liquid particle forming: open the heating and heat preservation facilities in the "forming machine", and at the same time send nitrogen into the machine and adjust the atmosphere, pressure and temperature, of which the oxygen atmosphere is 100ppm, and the temperature is 390 ° C ± 10 ° C; start the electromechanical Oscillating device, open the liquid discharge valve in the electric heating melting pot and put the alloy liquid into the SMT laser orifice plate container....

Embodiment 2

[0036] Prepare lead-free solder balls of 96Sn3.5Ag0.5Cu according to the method and steps of Example 1. Among them, the alloy melting temperature is 380°C±10°C, the SMT laser orifice plate container is 410°C±10°C, and the SMT laser orifice plate aperture is Φ0.06mm±0.005mm; other process parameters are the same as in Example 1, and the obtained solder ball particle size is Φ0.15mm±0.005mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com