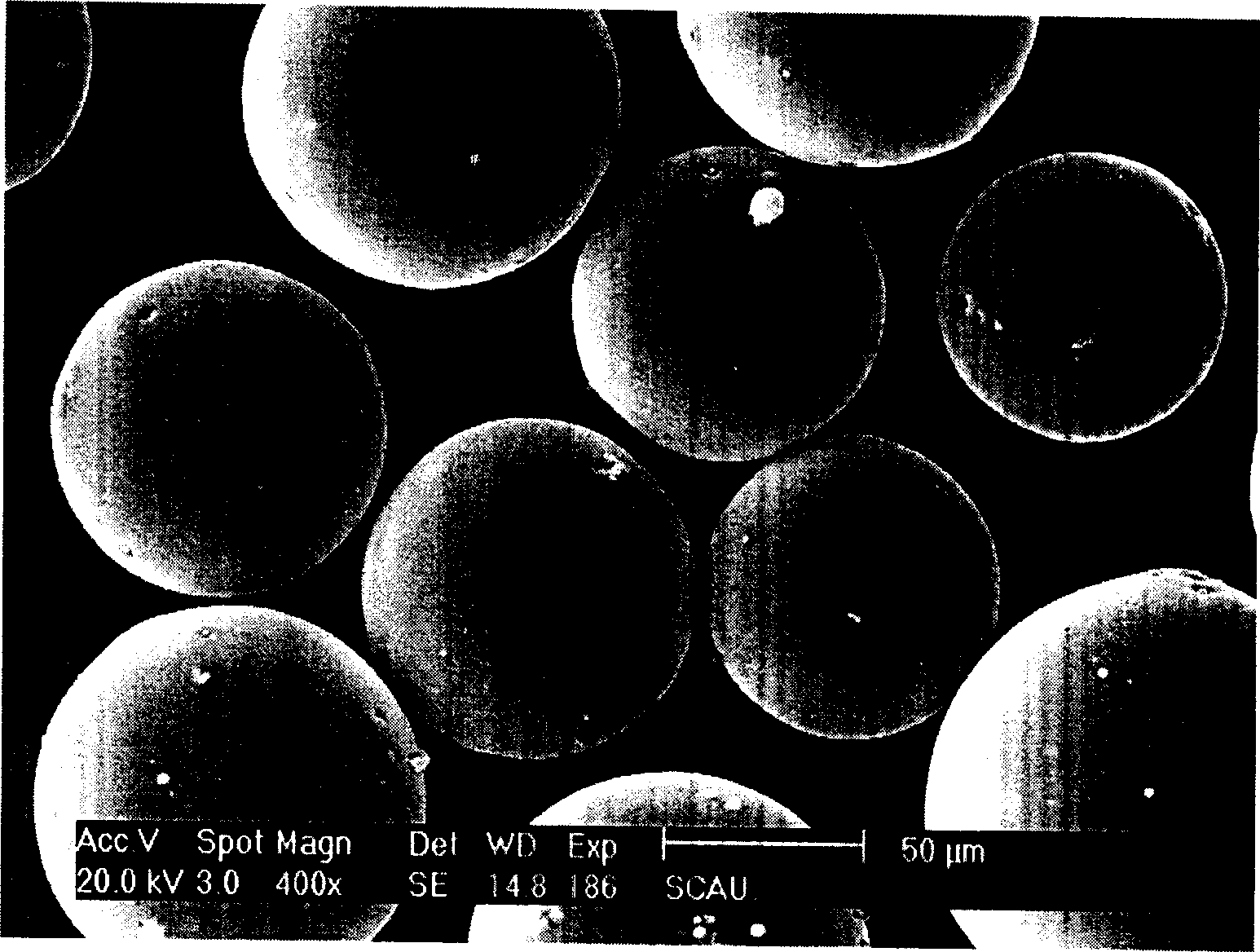

Process for preparing magnetic polymethyl methacrylate microsphere by two-step method

A technology of polymethyl methacrylate and methyl methacrylate, applied in the field of magnetic polymethyl methacrylate microspheres, can solve the problems of wide particle size distribution, difficult control of polymerization conditions, uneven distribution of magnetic content, and the like, Achieve narrow particle size distribution, eliminate thermal expansion coefficient mismatch, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Two-step method of the present invention prepares the method for magnetic polymethyl methacrylate microsphere to comprise the steps:

[0035] The first step, preparing polymethyl methacrylate microspheres, including

[0036] (1) dispersant is dissolved in distilled water; Described dispersant is magnesium hydroxide, and the mass ratio with water is 1: 100;

[0037] (2) add initiator in methyl methacrylate, and make initiator dissolve completely; Described initiator is dibenzoyl peroxide, and the mass ratio with methyl methacrylate is 2: 100;

[0038] (3) the solution that step (1) is obtained is heated with stirring, and logical nitrogen 30min gets rid of the oxygen in the container, when temperature reaches 75 ℃, adding consumption is the concentrated sulfuric acid of 0.1% quality of described solution, then adds step (2) ) the solution that obtains, its consumption and the solution equivalence that step (1) obtains;

[0039] (4) After reacting at 60° C. for 2 hours,...

Embodiment 2

[0048] Two-step method of the present invention prepares the method for magnetic polymethyl methacrylate microsphere to comprise the steps:

[0049] The first step is to prepare polymethyl methacrylate microspheres, including

[0050] (1) Dispersant is dissolved in distilled water; Described dispersant is calcium phosphate, and the mass ratio with water is 3: 100;

[0051] (2) add initiator in methyl methacrylate, and make initiator dissolve completely; Described initiator is azobisisobutyronitrile, and the mass ratio with methyl methacrylate is 1: 100;

[0052] (3) the solution that step (1) is obtained is heated with stirring, and logical nitrogen 90min gets rid of the oxygen in the container, when temperature reaches 60 ℃, adding consumption is the concentrated sulfuric acid of 0.3% quality of described solution, then adds step (2) ) the solution that obtains, its consumption and the solution equivalence that step (1) obtains;

[0053] (4) After reacting at 90° C. for 2.5...

Embodiment 3

[0062] Two-step method of the present invention prepares the method for magnetic polymethyl methacrylate microsphere to comprise the steps:

[0063] The first step: prepare polymethyl methacrylate microspheres, including

[0064] (1) dispersant is dissolved in distilled water; Described dispersant is calcium phosphate and barium sulfate, and its mass ratio is 80: 20, and the mass ratio of dispersant and water is 2: 100;

[0065] (2) add initiator in methyl methacrylate, and make initiator dissolve completely; Described initiator is dibenzoyl peroxide, and the mass ratio with methyl methacrylate is 3: 100;

[0066] (3) the solution that step (1) is obtained is heated with stirring, and logical nitrogen 65min gets rid of the oxygen in the container, when temperature reaches 95 ℃, adding consumption is the concentrated sulfuric acid of 0.15% quality of described solution, then adds step (2) ) the solution that obtains, its consumption and the solution equivalence that step (1) o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com