Carbon doped silicon sheet with internal impurity absorbing function and production thereof

A carbon-silicon wafer and functional technology, applied in the field of carbon-doped silicon wafer preparation, can solve the problem of low micro-defect density, achieve good gettering effect, high internal gettering capacity, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

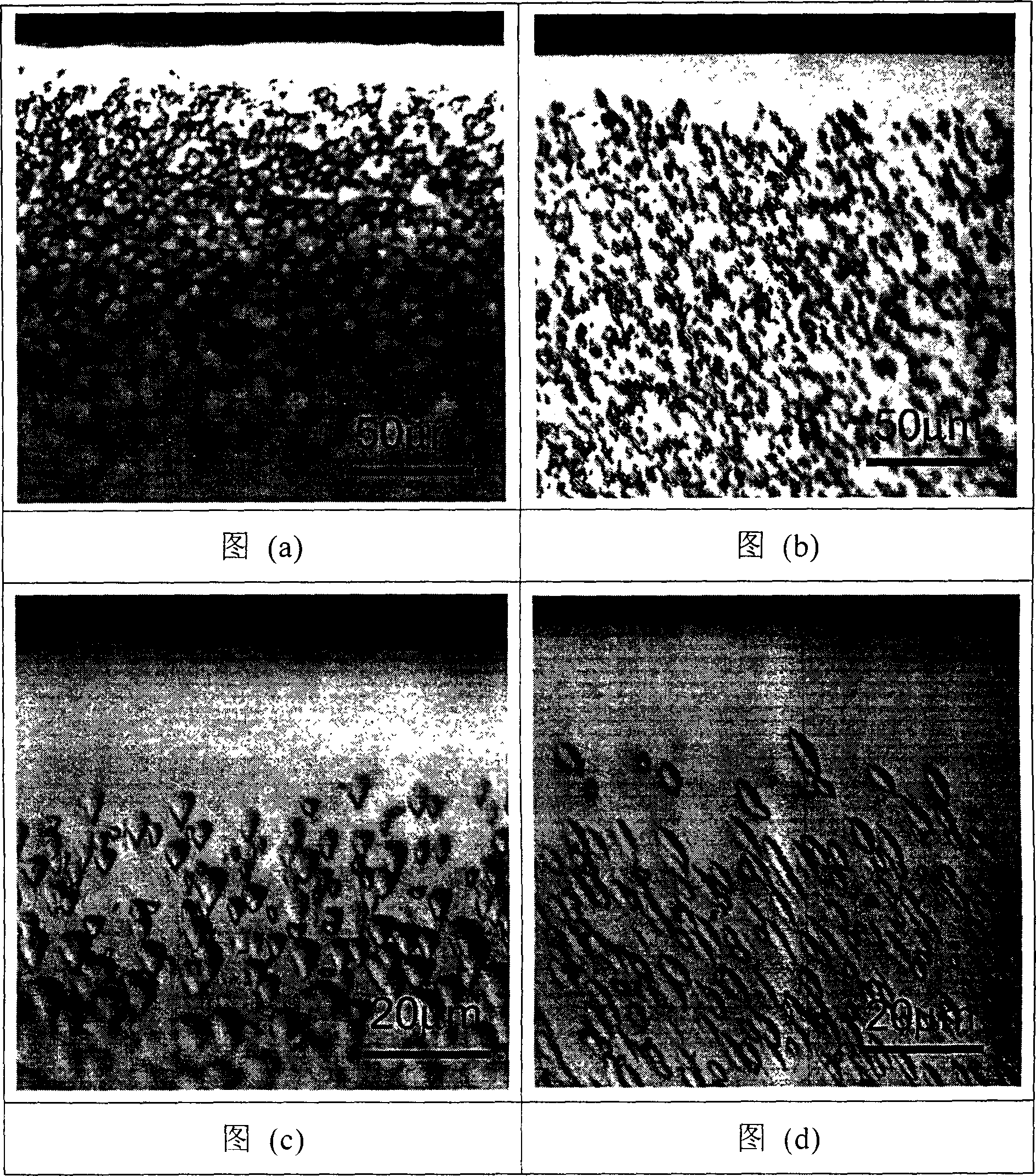

[0014] Select a 3-inch carbon-doped Czochralski silicon wafer (HCCZ-Si) grown under the protection of argon, with a carbon concentration of 1×10 17 cm -3 , the oxygen concentration is 8×10 17 cm -3 , The resistivity is 10 ohms. cm. In order to form a clean area and a bulk defect area in the silicon wafer, the silicon wafer is kept in a heat treatment furnace at 1200°C for 2 hours, then at 750°C for 16 hours, and after the treatment is completed at 1050°C for 16 hours. All heat treatments were performed under an argon atmosphere. After heat treatment, the silicon wafer was cleaved and etched in Sirtl preferential etching solution for 5 minutes, and then the distribution of defects on the cleavage plane was observed and photographed with an OLYMPUS MX50 microscope.

[0015] For comparison, an ordinary Czochralski silicon single crystal (CZ-Si) with the same oxygen concentration and resistivity, and a carbon concentration below the infrared detection limit, was also subjected...

Embodiment 2

[0018] Choose a 3-inch carbon-doped Czochralski silicon wafer grown under the protection of argon, with a carbon concentration of 5×10 16 cm -3 , the oxygen concentration is 15×10 17 cm -3 , The resistivity is 1 ohm. cm. Put the silicon wafer into the heat treatment furnace at 1150°C and keep it warm for 2 hours, then keep it at 650°C for 50 hours, and keep it at 1100°C for 6 hours after the treatment. All heat treatments were performed under an argon atmosphere. A silicon wafer with internal gettering ability can be obtained, with a certain width of defect-free clean area near the surface and a certain density of micro-defects (oxygen precipitation and secondary defects) in the body.

Embodiment 3

[0020] Select a 4-inch carbon-doped Czochralski silicon wafer grown under the protection of argon, with a carbon concentration of 3×10 17 cm -3 , the oxygen concentration is 6×10 17 cm -3 , The resistivity is 20 ohms. cm. Put the silicon wafer into the heat treatment furnace at 1250°C and keep it warm for 0.5 hours, then keep it at 850°C for 10 hours, and keep it at 1200°C for 20 hours after the treatment. All heat treatments were performed under an argon atmosphere. It is also possible to obtain a silicon wafer with internal gettering ability, a clean area with a certain width and no defects near the surface, and a certain density of micro-defects (oxygen precipitation and secondary defects) in the body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com