Method for preparing pharmaceutics of hydrolysate of brain protein

A technology for cerebroprotein hydrolysate and preparation, which is applied in the field of preparation of cerebroprotein hydrolysate preparation, can solve the problems of long production cycle, complicated operation, high price, etc., and achieves reduced production environment requirements, reduced probability of deterioration, and simple and easy operation. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

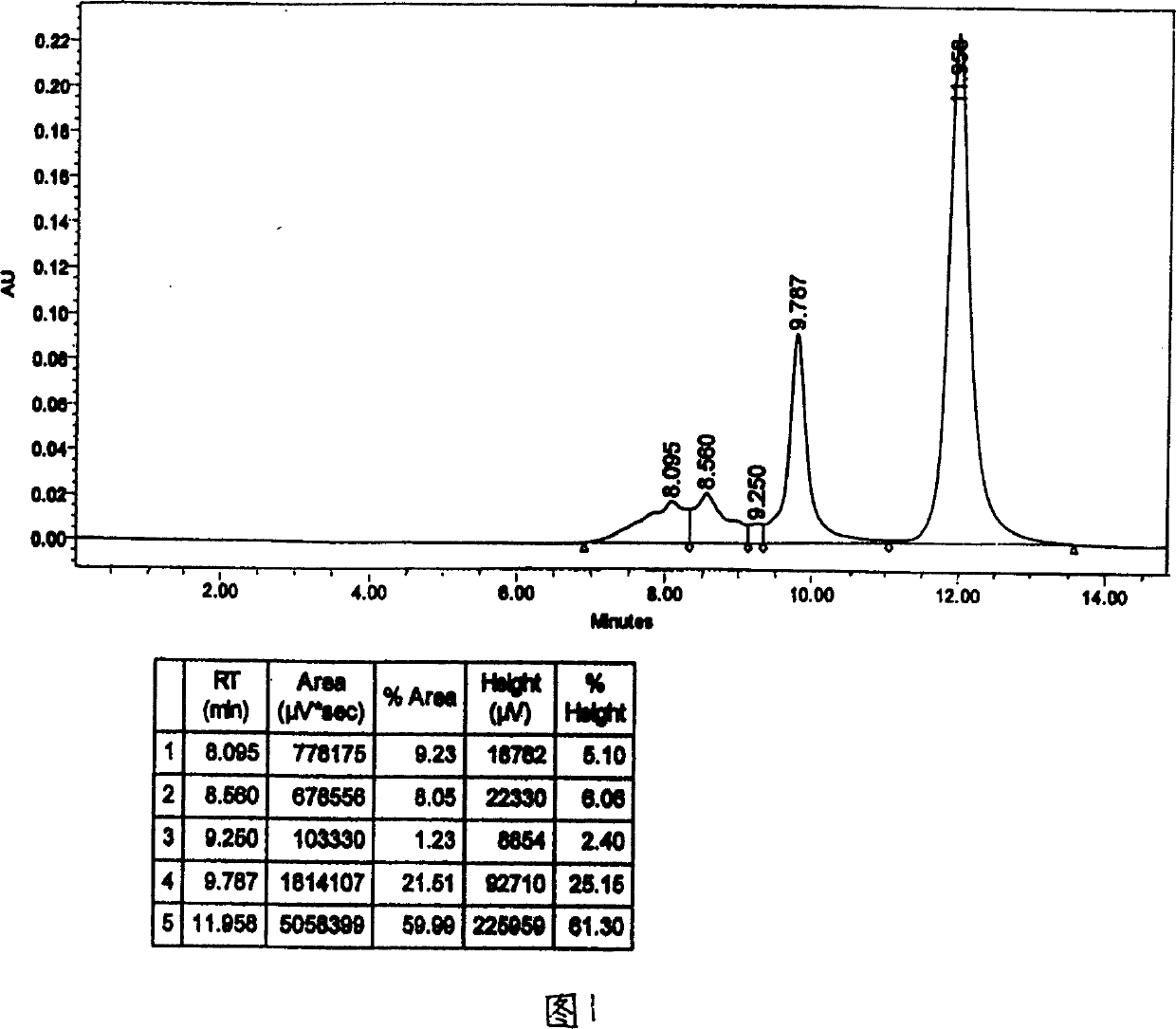

Image

Examples

Embodiment 1

[0017] 1. Take 100 kg of fresh pig brain, remove the capsule and blood vessels on the surface, add 100L of purified water (hereinafter referred to as water) while homogenizing, heat to 85°C with water steam, 15 minutes, and quickly cool down to 40°C 6mol / L hydrochloric acid to adjust the pH to 1.5, add 3Kg pepsin for enzymolysis for 3 hours, adjust the pH to 8.0 with 12mol / L sodium hydroxide, add 2Kg trypsin multienzyme (trypsin, pancreatic lipase and pancreatic starch enzyme), add 0.04mol / L CaCl before use 2 Activate trypsin multienzyme for 1 hour, enzymatically hydrolyze for 2 hours at 42°C, then adjust the pH value to 3.0 with 6mol / L hydrochloric acid, and freeze at -20°C for 12 hours; Filter through gauze, add sodium hydroxide to adjust the pH value to neutral, filter and clarify with a microporous membrane with a pore size of 1.0 μm, take the clarified liquid, and ultrafilter with an ultrafiltration membrane with a molecular weight cut-off of 10,000 to collect the permeat...

Embodiment 2

[0019] Take 100 kg of fresh pig brain, remove the capsule and blood vessels on the surface, add 200L of purified water (hereinafter referred to as water) while homogenizing, heat to 80°C with water steam for 15 minutes, and quickly cool down to 45°C, Use 6mol / L hydrochloric acid to adjust the pH to 2.0, add 3Kg pepsin for enzymatic hydrolysis for 12 hours, then use 12mol / L sodium hydroxide to adjust the pH to 7.7, add 2Kg trypsinase, and add 0.04mol / L CaCl before use 2Activate trypsin multienzyme for 0.5 hours, enzymatically hydrolyze for 4 hours at 38°C, then adjust the pH value to 2.0 with 6mol / L hydrochloric acid, and freeze at -10°C for 48 hours; at room temperature, use multi-layer Filter through gauze, add sodium hydroxide to adjust the pH value to neutral, filter and clarify with a microporous membrane with a pore size of 0.2 μm, take the clarified liquid, and ultrafilter with an ultrafiltration membrane with a molecular weight cut-off of 10,000 to collect the permeate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com