Method for manufacturing uranium foils containing fine crystals

A crystal and melt technology, applied in the field of manufacturing uranium foil containing fine crystals, can solve problems such as destruction and deformation of uranium foil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

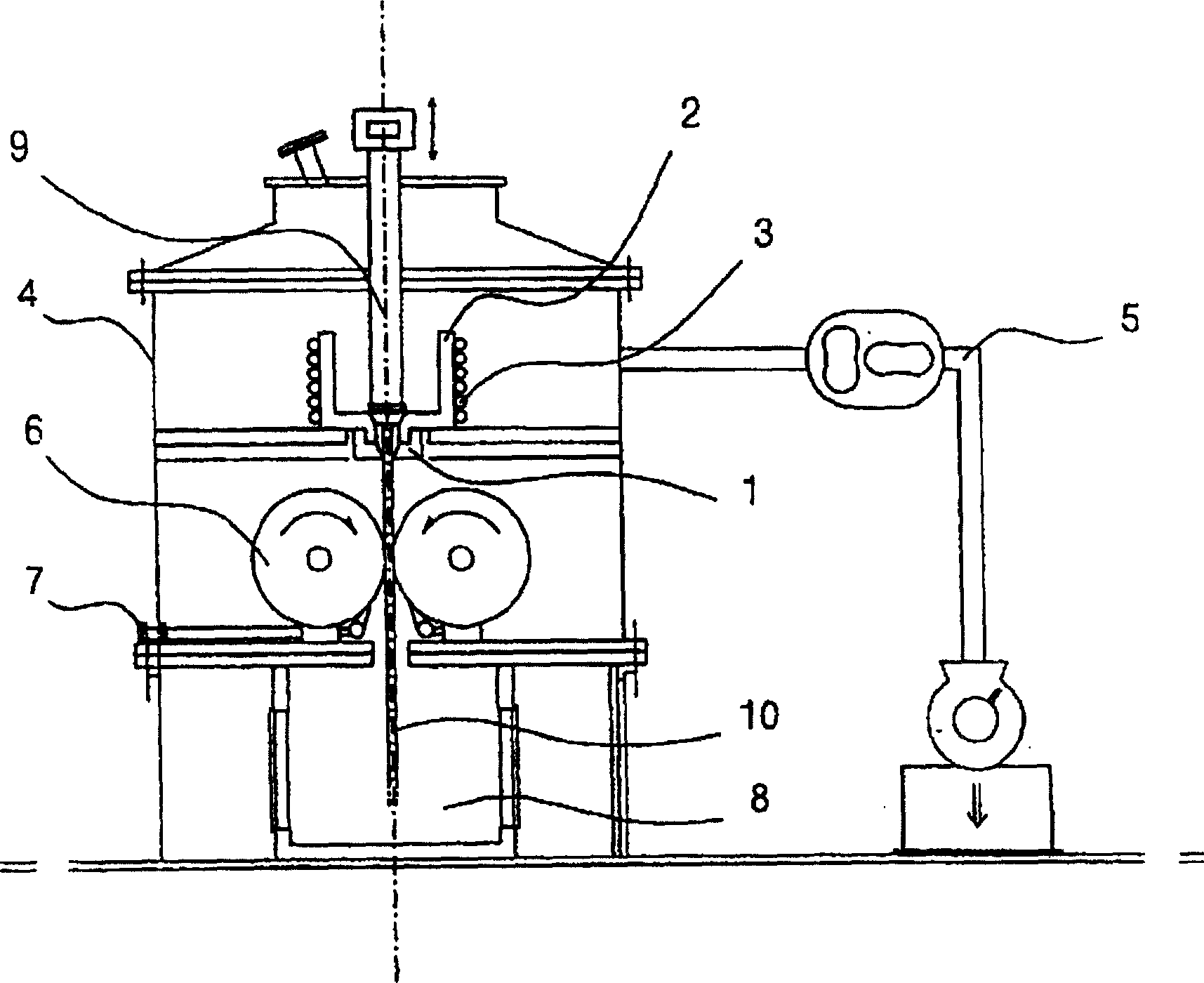

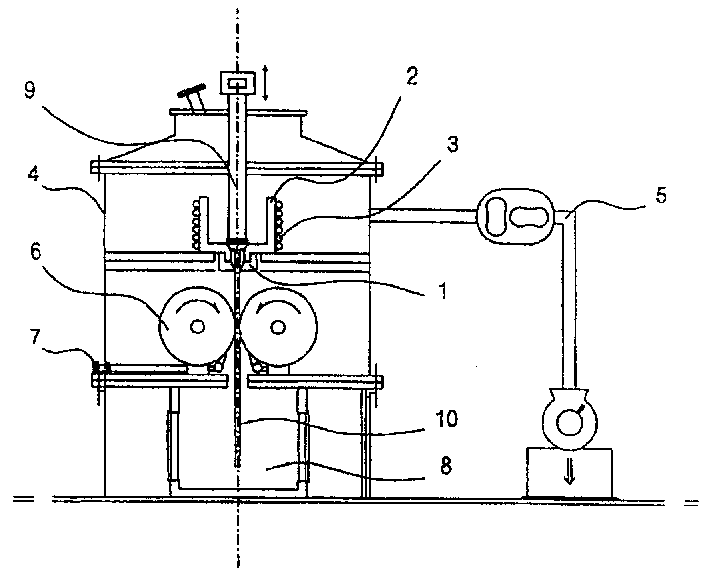

[0027] To manufacture low- or high-enriched uranium foils, uranium material is charged into a refractory crucible (2) with slots (1). The crucible (2) and insulating material (not shown) are assembled in the manufacturing apparatus in proper order.

[0028] Then, the steel chamber equipped with crucible (2) in the device is evacuated to 10 by vacuum pump system (5). -3 tor or higher.

[0029] The high frequency generator (3) is operated to superheat the contents of the crucible to about 200°C above the melting temperature of uranium.

[0030] When the rotation speed of the roller (6) driven by the electric motor is stabilized at about 300 rpm, the plug (9) placed in the crucible (2) is lifted up to discharge the alloy melt.

[0031] The outgoing alloy melt passes through a 1 mm wide slot (1) and then enters the middle of preheated side baffles (not shown) and a roll (6) rotating at about 300 rpm to form a thin foil (10).

[0032] Then, the air inlet valve (7) is operated to...

Embodiment 2

[0037] The invention is applied to low or highly enriched uranium [U-(A)Q-(B)X-(C)Y (Q: Al, Fe, Ni, Si, Cr, Zr elements, X: Al , Fe, Ni, Si, Cr, Zr elements, Y: Al, Fe, Ni, Si, Cr, Zr elements, Q≠X≠Y, (A)≤1% (weight), (B)≤1% ( weight), (C)≤1% (weight))] foil of uranium alloy.

[0038] In order to manufacture U-500ppm Fe-1200ppm Al-500ppm Ni alloy foil, uranium and doping elements including Fe, Al and Ni are appropriately weighed and packed in the crucible according to the required alloy composition. The steel chamber (4) was evacuated to 10 using the vacuum pump system (5) described in the process of making uranium foil. -3 tor or higher.

[0039] Likewise, when the crucible (2) and insulating material (not shown) are installed in the apparatus in proper sequence, the high frequency generator (3) is operated to superheat the contents of the crucible to a temperature higher than that of uranium alloy The melting temperature is about 200°C higher.

[0040] When the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com