Multi-layer ceramic capacitor material with dielectric constant and temp stability and its preparing process

A temperature-stable, multi-layer ceramic technology, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, ceramics, etc., can solve the problems of complex sintering process, etc., and achieve easy control of sintering process, small dielectric loss, and high insulation resistivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

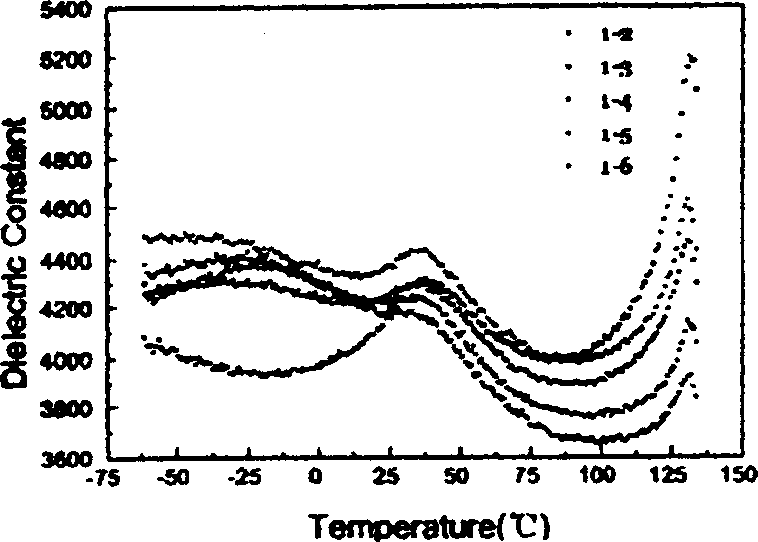

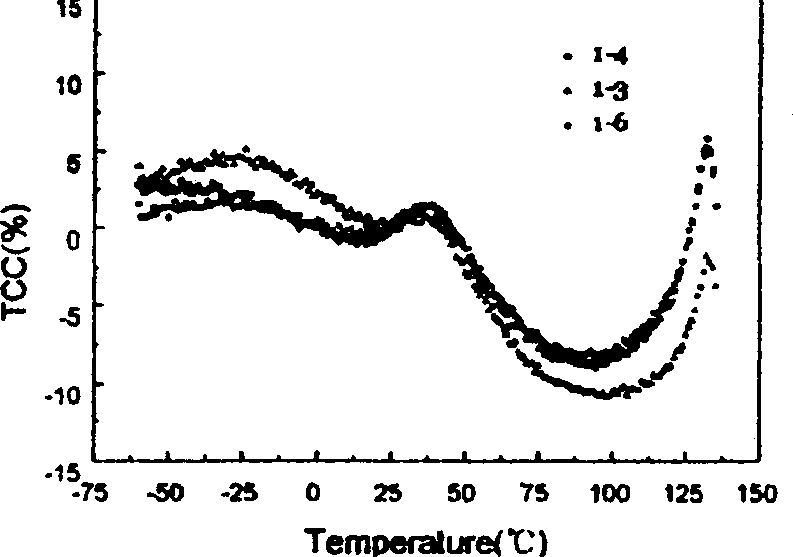

[0028] Embodiment 1, taking Nb, Co, Nd element doping as an example. The amount of fixed additives Nb and Co is 1.0 mol%. Nb:Co=2.5. Barium titanate (BaTiO 3 ) The main material is prepared by chemical synthesis method, and its initial raw material is tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) 102.1g dissolved in ethanol, barium acetate (Ba(CH 3 COO) 2 ) is 76.64g soluble in water, oxalic acid (H 2 C 2 o 4 2H 2 O) 83.2g was dissolved in ethanol. Firstly add tetrabutyl titanate ethanol solution into oxalate ethanol solution, stir evenly, then slowly add barium acetate aqueous solution to form white precipitate of barium titanyl oxalate. The precipitate is firstly washed several times with deionized water, and then washed several times with ethanol, then dried and calcined to obtain white barium titanate powder material. Add secondary additives to 20g of barium titanate powder according to the formula, the content of niobium oxide and cobalt oxide in the formula is 1.0mo...

Embodiment 2

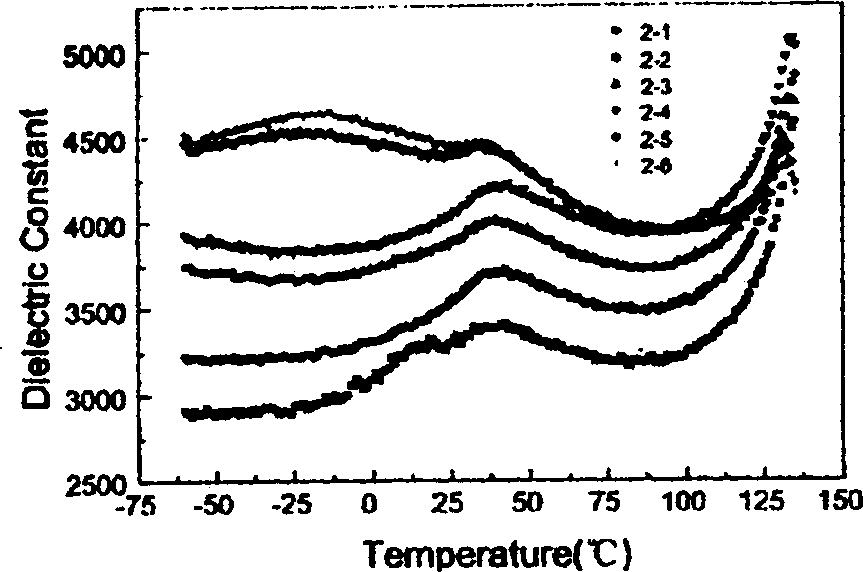

[0029] Example 2: Fixed formula The main ingredient is barium titanate at 98 mol%, the contents of niobium oxide and cobalt oxide at 1.0 mol%, and neodymium oxide at 1.0 mol%. Barium titanate was prepared by the chemical synthesis method in Example 1. Add secondary additives to 20 g of barium titanate powder according to the formula in Example 1. The ingredients are mixed by ball milling, and after drying, press molding under a pressure of 2 MPa, with a diameter of 10 mm and a thickness of 1 mm. Sinter at 1200°C, 1220°C, 1240°C, 1250°C, 1260°C, 1280°C for 2 hours. The heating rate is 6°C / min. The dielectric properties of the fired tiles were measured after firing silver on the upper and lower surfaces. The dielectric performance parameters of the obtained ceramic samples are shown in Table 2. image 3 The curve shows the dielectric temperature characteristic curve of the sample. Figure 4 Give the volumetric temperature change rate curve of the sample.

Embodiment 3

[0030] Example 3: Use and weigh three groups of 20g barium titanate, add secondary additives according to the formula in Example 1, and then add 0.2g, 1.0g, 2.0g metal silver powder respectively, recorded as 3-1, 3-2, 3- 3. The ingredients are mixed by alcohol ball mill, dried, molded under 2MPa pressure, sintered at 1240℃, and the holding time is 2 hours. The dielectric properties of the obtained ceramic samples were tested after firing silver. Table 3 lists the dielectric performance parameters of ceramic samples with different metal Ag powder additions under 1240°C sintering. Figure 5 with Image 6 are the dielectric temperature characteristic curve and capacity temperature change rate curve of the sample, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com