Selective laser melting TC4 alloy-based composite material as well as preparation method and application thereof

A technology of selective laser melting and composite materials, which is applied in metal material coating technology, additive processing, pharmaceutical formulations, etc. Improve physical and chemical bonding, improve surface quality, and promote the effect of chemical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

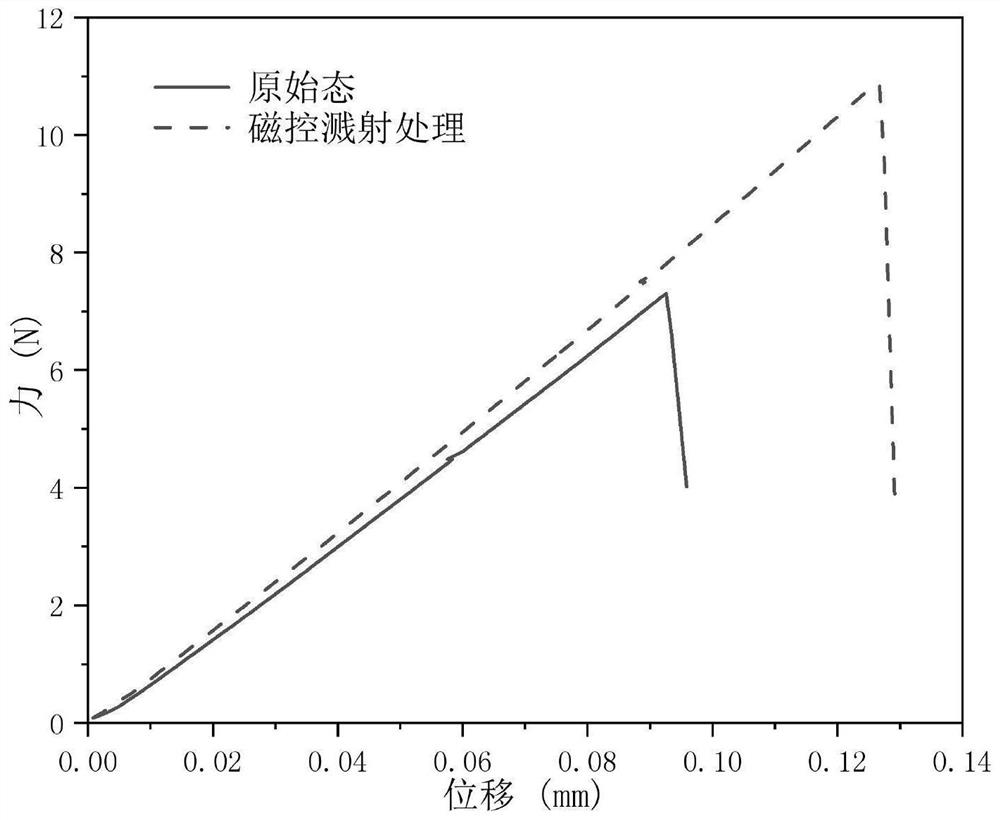

[0023] The invention provides a preparation method for selective laser melting of TC4 alloy matrix composite material, comprising the following steps:

[0024] (1) Corrosion treatment of selective laser melting of TC4 alloy with acid solution to obtain surface corrosion alloy;

[0025] (2) Coating treatment is performed on the surface of the surface corrosion alloy obtained in the step (1) to obtain a selective laser melting TC4 alloy-based composite material with a nickel-chromium-molybdenum alloy coating on the surface.

[0026] In the invention, the acid solution is used to perform corrosion treatment on the selective laser melting of the TC4 alloy to obtain a surface corrosion alloy. The invention performs corrosion treatment on the selective laser melting of the TC4 alloy, which can remove the inclusions and stress layers on the surface thereof, which is beneficial to the subsequent coating treatment.

[0027] In the present invention, the chemical composition of the sel...

Embodiment 1

[0049] A preparation method for selective laser melting of TC4 alloy-based composite materials, comprising the following steps:

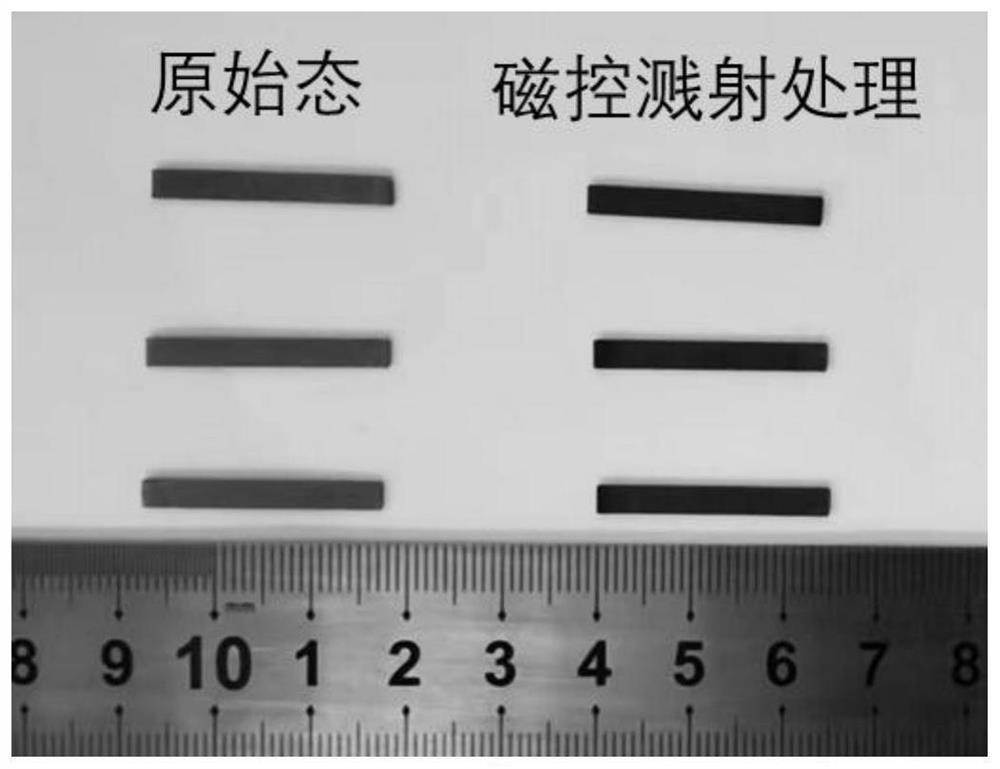

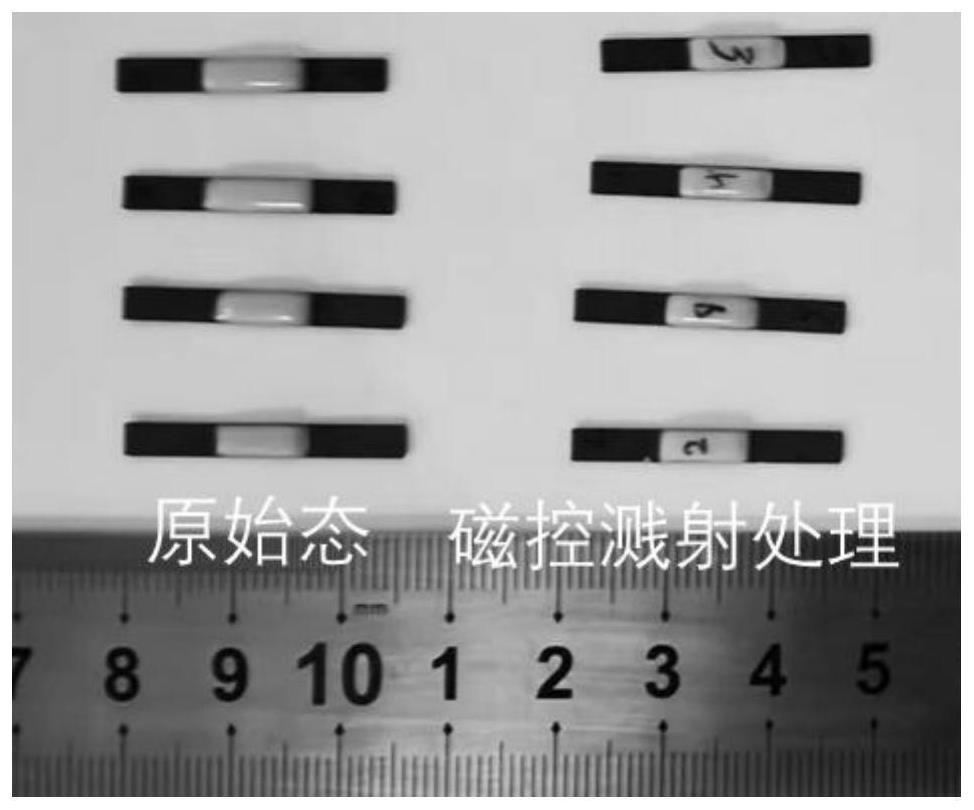

[0050] (1) The selective laser melting TC4 alloy was placed in a mixed solution of hydrochloric acid and hydrofluoric acid, and the corrosion treatment was carried out at 30 °C for 1 min, and the surface corrosion alloy was obtained after washing with water and ethanol; wherein, the selective laser melting of the TC4 alloy The preparation method is as follows: TC4 alloy powder (in terms of mass percentage: Al 5%, V 3%, Fe<0.25%, and the remainder is Ti) is printed with a selective laser melting device (metal 3D printer) to prepare a metal block, Using the method of mechanical cutting, it is prepared into a 25×3×0.5mm sheet; the concentration of hydrochloric acid in the mixed solution is 5wt.%, and the concentration of hydrofluoric acid is 1wt.%;

[0051] (2) Coating treatment is performed on the surface of the surface corrosion alloy obtained in the...

Embodiment 2

[0065] A preparation method for selective laser melting of TC4 alloy-based composite materials, comprising the following steps:

[0066] (1) The selective laser melting TC4 alloy was placed in a mixed solution of hydrochloric acid and hydrofluoric acid, and the corrosion treatment was carried out at 25 ° C for 2 minutes, and the surface corrosion alloy was obtained after washing with water and ethanol; wherein, the selective laser melting of the TC4 alloy was The preparation method is as follows: TC4 alloy powder (calculated by mass percentage: Al 7%, V 5%, Fe<0.25%, and the balance is Ti) is printed with a selective laser melting device (metal 3D printer) to prepare a metal block, Using the method of mechanical cutting, it is prepared into a 25×3×0.5mm sheet; the concentration of hydrochloric acid in the mixed solution is 10wt.%, and the concentration of hydrofluoric acid is 2wt.%;

[0067] (2) Coating treatment is performed on the surface of the surface corrosion alloy obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com