NiAl/AlSiON multi-layer composite coating resistant to high-temperature oxidation and preparation method of NiAl/AlSiON multi-layer composite coating

A high-temperature oxidation-resistant, multi-layer composite technology, applied in coating, metal material coating process, high-efficiency propulsion technology, etc., can solve problems such as peeling, and achieve the effects of easy control of thickness, continuous sub-layer structure, and fast deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

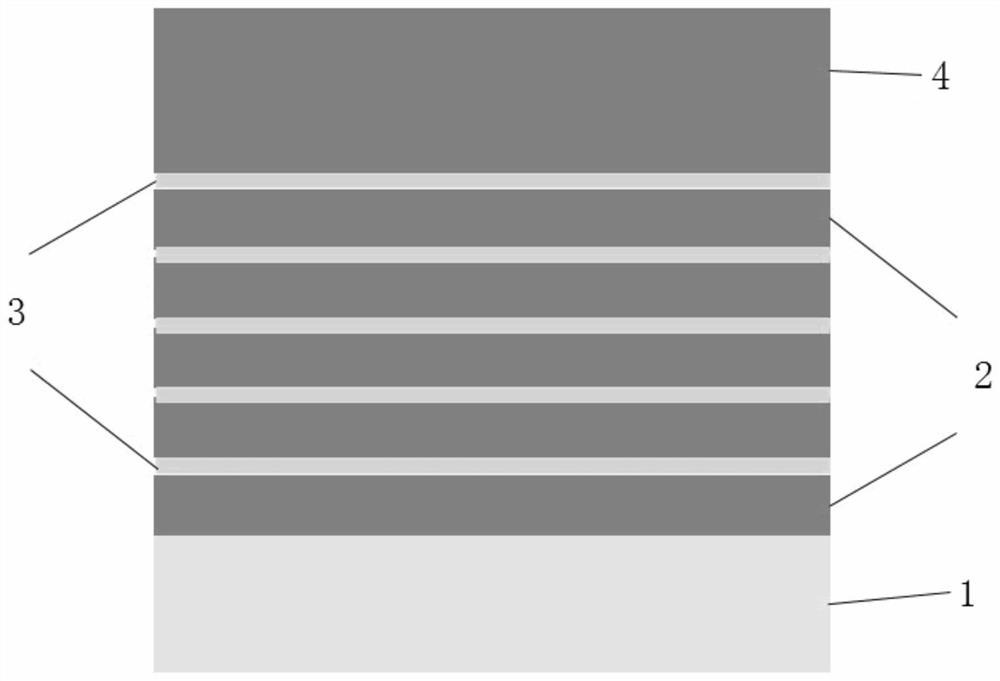

[0048] In the following specific implementation process, the high-temperature oxidation-resistant NiAl / AlSiON multi-layer composite coating and preparation method of the present invention are as follows: the multi-layer composite coating is prepared by using ion plating-sputtering co-deposition equipment, the AlSiON layer is prepared by ion plating technology, and the Magnetron sputtering to prepare NiAl metal sublayer, using AlSi target as ion plating cathode target to prepare AlSiON layer, using Ni 3 Al and Al targets are used as magnetron sputtering cathode targets to prepare NiAl metal sublayers. NiAl / AlSiON multilayer composite coatings are alternately deposited on various titanium alloys and titanium aluminum alloy substrates by AlSiON sublayers and NiAl metal sublayers. , the first layer and the top layer are both AlSiON layers; in the multi-layer composite coating, the thickness of each NiAl metal sub-layer is 0.05-0.5 μm, the number of layers is 5-9, the thickness of t...

Embodiment 1

[0052] In this embodiment, the preparation method of the NiAl / AlSiON multi-layer composite coating resistant to high temperature oxidation includes the following steps:

[0053] (1) Pre-processing

[0054] Using Ti-6Al-4V (wt.%) titanium alloy as the matrix, the sample was cut into a matrix material with a size of 15mm × 10mm × 1.5mm by wire cutting. After polishing the diamond paste, put the matrix into a mixed solution of acetone and ethanol, ultrasonically clean it for 10 minutes, and further remove oil and other solid contaminants on the surface of the matrix. Take it out and dry it, then hang it on the sample holder, and finally put it in the working room and put it into the working chamber. Vacuum to 7.0×10 -3 Pa.

[0055] (2) Sputtering bombardment cleaning

[0056] Composite coatings were prepared using ion plating-sputtering co-deposition equipment. Pour in argon gas, adjust the flow rate to control the argon pressure at 0.1Pa, apply a negative bias value of 800V ...

Embodiment 2

[0062]In this embodiment, the preparation method of the NiAl / AlSiON multilayer composite coating resistant to high temperature oxidation specifically includes the following steps:

[0063] (1) Pre-processing

[0064] Using Ti-5Al-2.5Sn (wt.%) titanium alloy as the matrix, the sample was cut into a matrix material with a size of 10mm × 10mm × 2mm by wire cutting. After polishing the diamond paste, put the matrix material into a mixed solution of acetone and ethanol, ultrasonically clean it for 15 minutes to further remove oil and other solid contaminants on the surface of the matrix, take it out and dry it, quickly hang it on the sample holder, and finally put it into the studio and evacuated to 6.0×10 -3 Pa.

[0065] (2) Sputtering bombardment cleaning

[0066] Coatings were prepared using ion plating-sputtering co-deposition equipment. Argon gas was introduced, the pressure was controlled at 0.2Pa, the substrate was applied with a negative bias value of 850V, the duty cyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap