WCN thin film deposition method with adjustable work function

A thin film deposition and work function technology, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of difficulty in mass production, polysilicon depletion effect, uncontrolled adjustment range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

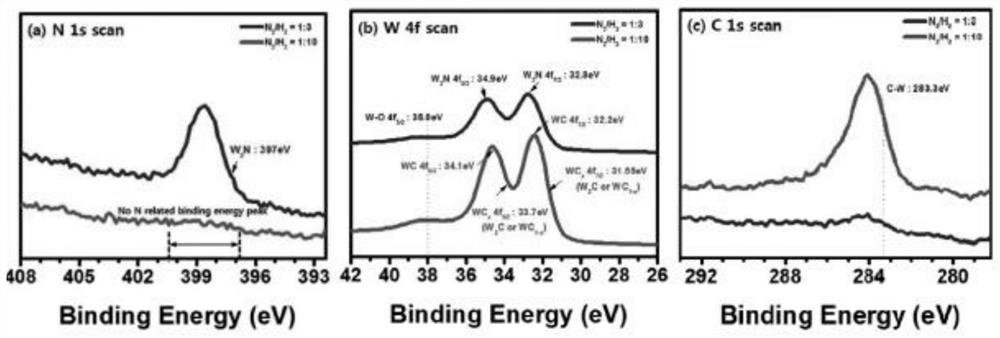

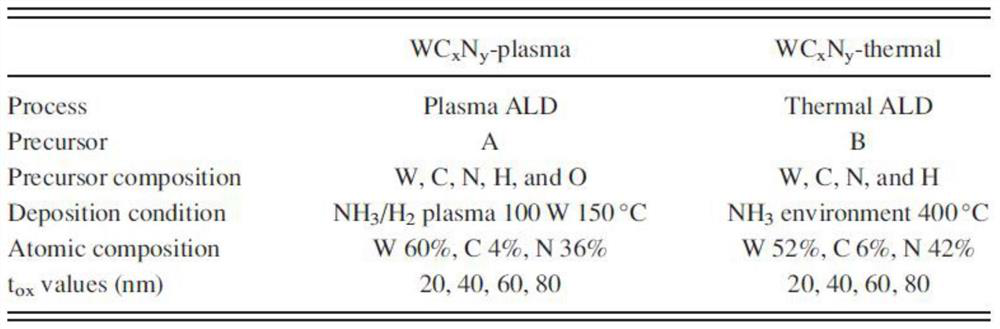

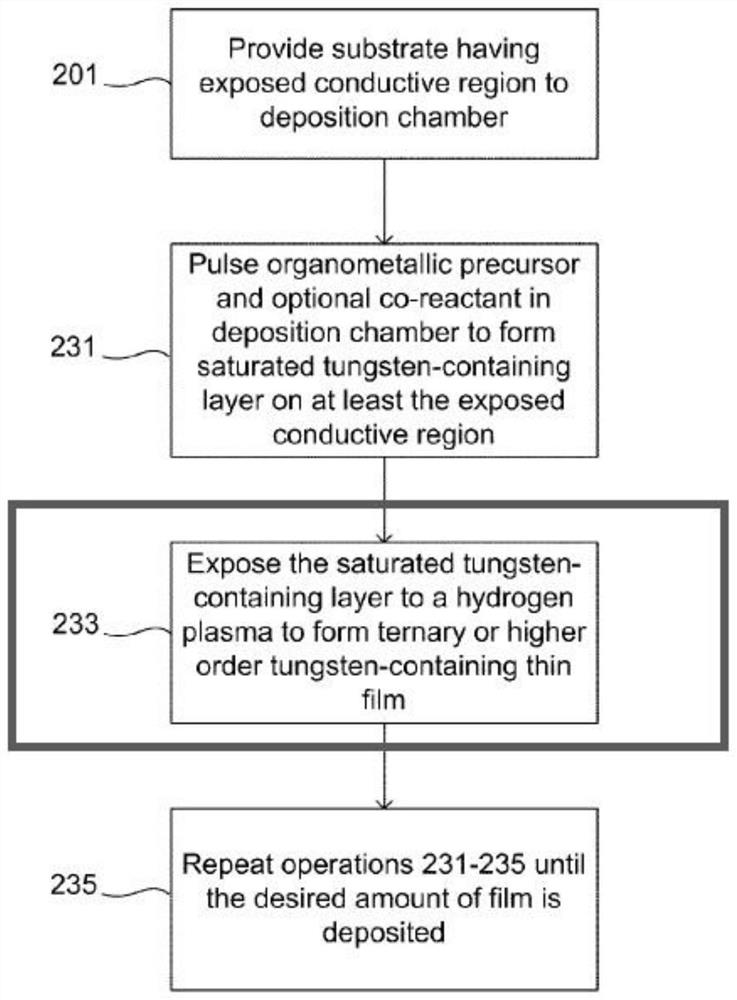

[0034] like Figure 4 As shown in (A), a WCN thin film deposition method with tunable work function includes the following steps:

[0035] (1) The substrate is subjected to pretreatment to clean and activate the substrate surface. The pretreatment includes ozone treatment, oxygen plasma treatment, ammonia gas plasma treatment, hydrogen plasma treatment and mixed gas plasma treatment;

[0036] (2) Heating the tungsten precursor to 90°C, heating the precursor transport pipeline and valve to 120°C, heating the ALD chamber temperature to 300°C, and evacuating the ALD chamber to 1Pa;

[0037](3) The tungsten precursor is introduced into the ALD cavity through an inert gas carrier gas, and the tungsten precursor forms chemical adsorption on the surface of the substrate. The tungsten precursor is bis(tert-butylimino)bis(dimethylamino) tungsten , and its chemical structure is as follows:

[0038]

[0039] (4) The unadsorbed precursor and the by-product of the reaction are purged ...

Embodiment 2

[0051] like Figure 4 (B), a work function tunable WCN thin film deposition method, comprising the following steps:

[0052] (1) The substrate is subjected to pretreatment to clean and activate the substrate surface. The pretreatment includes ozone treatment, oxygen plasma treatment, ammonia gas plasma treatment, hydrogen plasma treatment and mixed gas plasma treatment;

[0053] (2) Heating the tungsten precursor to 100°C, heating the precursor transport pipeline and valve to 120°C, heating the ALD chamber temperature to 250°C, and evacuating the ALD chamber to 0.5Pa;

[0054] (3) The tungsten precursor is then introduced into the ALD cavity through an inert gas carrier gas, and the tungsten precursor forms chemical adsorption on the surface of the substrate. The tungsten precursor is bis(tert-butylimide) bis(dimethylamine) Tungsten;

[0055] (4) The unadsorbed precursor and the by-product of the reaction are purged with an inert gas, and the purge time is 20s;

[0056] (5)...

Embodiment 3

[0067] A WCN thin film deposition method with adjustable work function, comprising the following steps:

[0068] (1) The substrate is subjected to pretreatment to clean and activate the substrate surface. The pretreatment includes ozone treatment, oxygen plasma treatment, ammonia gas plasma treatment, hydrogen plasma treatment and mixed gas plasma treatment;

[0069] (2) Heating the tungsten precursor to 100°C, heating the precursor transport pipeline and valve to 125°C, heating the ALD chamber temperature to 300°C, and evacuating the ALD chamber to 1Pa;

[0070] (3) The tungsten precursor is introduced into the ALD cavity through an inert gas carrier gas, and the tungsten precursor forms chemical adsorption on the surface of the substrate. The chemical structural formula is as follows:

[0071]

[0072] (4) The unadsorbed precursor and the by-product of the reaction are purged with an inert gas, and the purge time is 20s;

[0073] (5) Pass the reaction gas NH into the AL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com